Search

Search

Search

Search

Halliburton's superior performance and consistent delivery reduces time and maximizes efficiency.

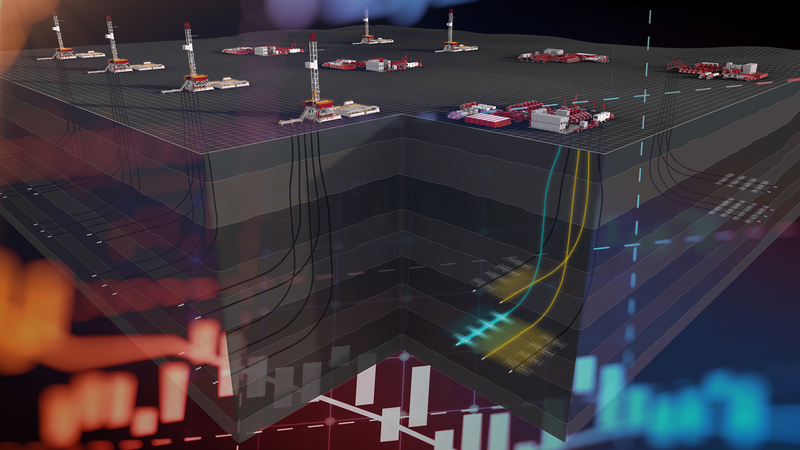

Talk to an expertOur presence in the Permian is built on our commitment to safety, execution, and collaboration to help customers maximize value throughout the lifecycle of the reservoir. From subsurface analysis to abandonment, we work closely with operators in the dynamic and challenging landscapes of the region to achieve success at every stage.

We combine technology, services, and execution expertise to assist our customers with hydrocarbon location, geological data management, drilling and formation evaluation, well construction and completion, and production optimization throughout the life of their asset.

Permian basin

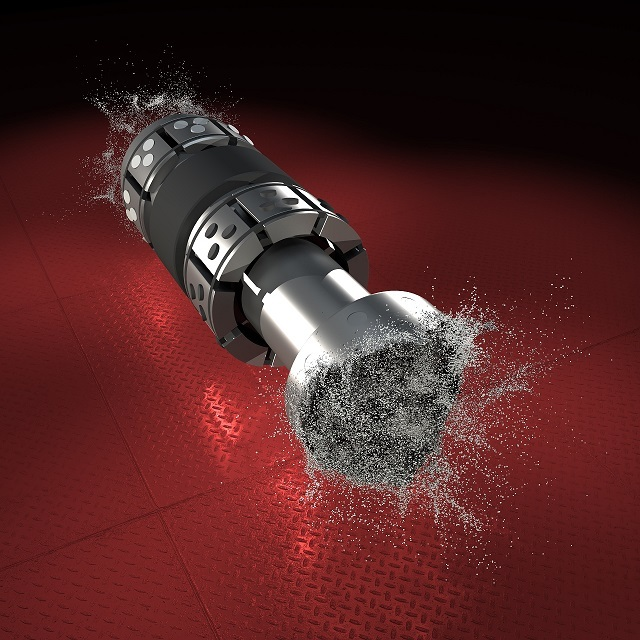

During this run, the operator set a record in the Permian Basin for single-run footage. The HyperSteer™ directional drill bit technology and drilling strategy helped the operator reduce costs through the elimination of trips and reduced operational time.

explore hypersteer

permian basin - january 2025

Halliburton and Coterra Energy Inc. announced the launch of autonomous hydraulic fracturing technology in North America with the Octiv® Auto Frac service, which is part of the ZEUS IQ™ intelligent fracturing platform. This technology automates stage delivery execution with the push of a button. Coterra is the first operator to fully automate and control their hydraulic fracturing design and execution.

read press releaseOur collaborative success in the Permian is not a result of individual efforts but a synergy of various elements working seamlessly together. We recognize that success is not a one-size-fits-all solution. Our approach is centered on understanding unique operator challenges and offering a comprehensive package that caters specifically to their needs.

permian basin

Hybrid permanent magnet motor achieves unmatched efficiency in challenging, gassy, and unconventional wells, setting new standards in performance and reliability.

read case studypermian basin

Sensori's fracture monitoring system empowered operators in the Permian to see, measure, and act on subsurface fracture behavior in real-time, enabling faster validation of completion design and optimization of fracture operations.

read case studydelaware basin

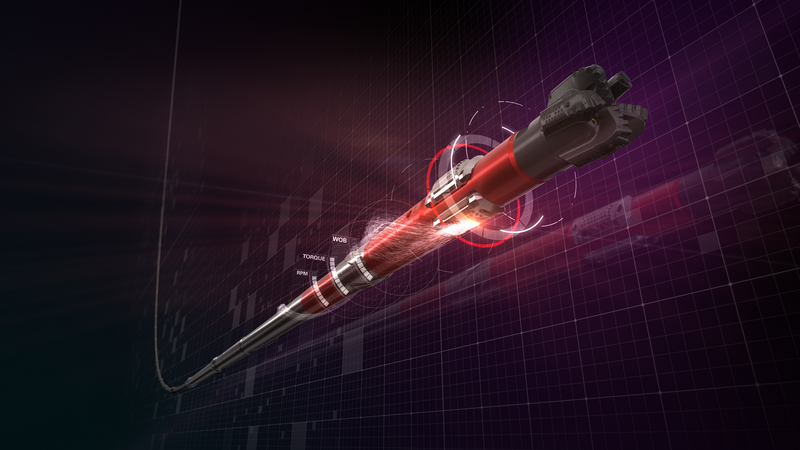

iCruise® CX intelligent RSS delivered outstanding drilling performance in the Barnett Shake, saving 6 days in the horizontal section, achieving 25% more footage, and boosting ROP by 14%.

explore icruise systemsWe help to provide valuable insights and service quality to maximize production. We integrate technology, services, tools, and local expertise to deliver efficient, reliable performance. We help to make real-time adjustments and hit the sweet spot to save cost and reach goals. It’s not about what we've achieved; it's about how we can help you achieve more to advance the future of energy.

delaware basin

Discover how operator increased oil production and generated $5.8MM in additional revenue by transitioning from gas lift to ESPs with the help of Intelevate digital platform.

read case studyPermian Basin

Discover how BaraSeal™-957 helps to enhance integrity by stabilizing microfractures, lowering fluid loss and minimizing wellbore invasion of filtrate in New Mexico.

READ CASE STUDY

Providing improved ESP system optimization and extensive customizable well monitoring to meet all your production needs.

This high-performance frac plug provides zonal isolation of the wellbore during stimulation treatment and customized dissolution times

The ExpressFiber disposable fiber cable is an economic, low-risk fiber solution for cross-well monitoring that provides direct measurement of well interference.

We are integrating insights, automation, and intelligence to improve the performance and efficiency of fracture operations.

Automation-enabled platform designed specifically for longer well applications in harsh environments.

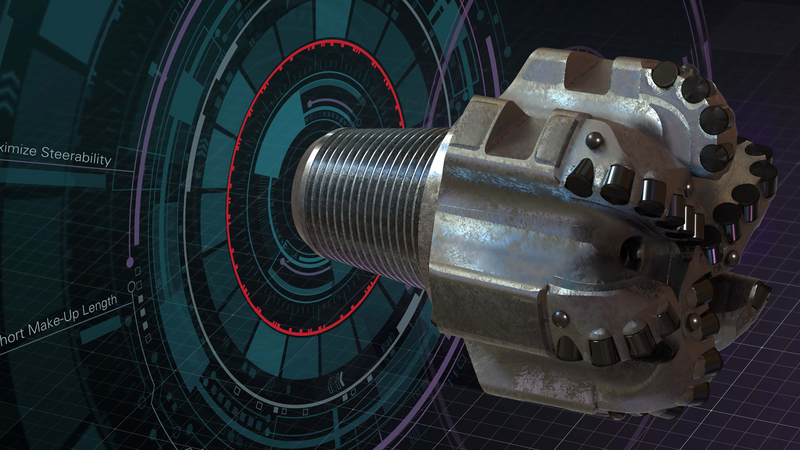

Directional drill bits designed for high build rates in curve and lateral applications.

An easy to deploy, cost-effective fracture monitoring solution for continuous measurement and visualization of the subsurface.

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Tracker® gauge pad technology provides steerability in the curve and stability in the lateral, increasing overall drilling efficiency.