Search

Search

Search

Search

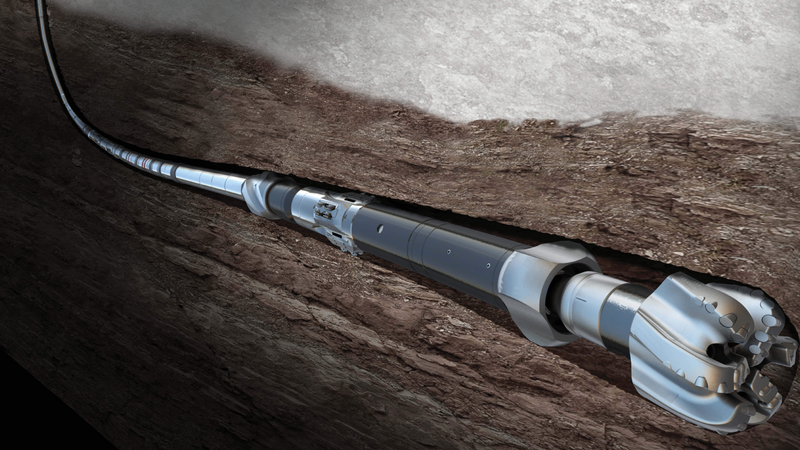

Prepare, clean, and complete the reservoir and reduce operational costs with advanced chemical and mechanical solutions

talk to an expertOptimize reservoir performance with completion fluids designed to improve wellbore cleanliness, prevent formation damage, and facilitate recovery. These high-performance fluids and custom systems preserve production zone permeability, maintain wellbore stability, and facilitate safe and effective downhole equipment installation. This equals higher initial production rates and improved long-term recovery from the reservoir.

Because every reservoir poses unique challenges, we tailor our completion fluid systems to meet specific reservoir conditions and operational requirements. Unlock the full potential of your assets with advanced fluid technologies that bolster operations and reduce costs.

Wellbore conditions vary by reservoir. The wrong fluid choice could lead to formation or equipment damage, reduced well productivity, and safety risks.

Halliburton’s fluid experts interpret each reservoir’s complexities and recommend completion fluid systems customized for your wellbore conditions. Our well completion fluids prepare, clean, and complete the wellbore. This helps you achieve maximum performance from your well through improved formation pressure control and minimized production zone damage.

Completion operations require operators to maintain wellbore stability and manage formation pressures. Uncontrolled pressures can lead to blowouts, well control incidents, or costly formation damage. We formulate fluids with the right density and chemical properties to minimize risks, protect personnel and assets, and ensure a smooth transition from drilling to production.

Completion fluids that invade the production zone can cause damage that reduces permeability and long-term well productivity. Our team of completion fluid experts works closely with you to select and design fluid systems that minimize damage. Advanced, reservoir-friendly chemistries and industry best practices provide you with completion fluids that help protect reservoir integrity and maximize hydrocarbon recovery.

When drilling fluids, debris, and contaminants remain in the wellbore, they can impede flow, reduce efficiency, and require remediation. Our comprehensive suite of wellbore cleaning solutions removes debris and contaminants to facilitate the wellbore’s readiness for completion and production. Cleaner wells result in higher production rates and fewer issues.

Harsh downhole environments and aggressive fluid chemistries can speed up corrosion. This threatens equipment integrity and increases maintenance costs. We engineer our completion fluids with proven corrosion inhibitors and treatment additives to protect costly equipment and completion hardware. The mitigation of corrosion risks extends equipment life and reduces downtime.

Formation damage, low permeability, and fluid invasion can restrict hydrocarbon flow. We designed our completion fluids to minimize skin damage and break up filter cake and other blockages. Our fluids help maintain wellbore stability and control formation pressure. This creates optimal conditions for stimulation treatments, such as acidizing or hydraulic fracturing projects. Technologies like wellbore-shielding additives prevent fluid filtrate from invading the production zone.

Difficult wellbore conditions, damage to the formation, and debris can complicate formation evaluation procedures. We formulated our completion fluids for compatibility with reservoir rock and fluids. This helps prevent alteration of formation properties or clogged pore spaces when logging and testing. Formation evaluation tools can gather more accurate data because our fluids remove debris and contaminants.

world oil article

What makes drilling in the Permian and Delaware unique is the advancements that operators and service companies have designed to push the technical limits of what is possible. At Halliburton, research and development never stop, and BaraSeal™-957 is testament to what we can achieve. Nanoparticle technology paves the way for the industry to deliver wells once considered too risky to drill.

read articleHalliburton offers a comprehensive portfolio of completion fluids and related systems. We designed each to address specific wellbore and reservoir conditions.

Brine-based completion fluids and wellbore cleanup fluids play a critical role in preparing the well for production. Brine-based fluids maintain wellbore stability, control formation pressure, and minimize formation damage during completion operations. Wellbore cleanup fluids remove drilling debris, residue, and contaminants to create a clean and efficient environment for the next phase.

Pressure management and well component integrity rely on packer fluids and breaker systems. Packer fluids help reduce or eliminate differential pressure across the packer, which extends its life and improves reliability. Our breaker systems remove filter cake from wellbore walls and boost reservoir productivity.

To safeguard downhole equipment and maintain fluid integrity, operators employ corrosion-control treatments and filtration solutions. Corrosion-control treatments mitigate the damaging effects of drilling and completion fluids, which preserves the longevity of critical components. Meanwhile, customized filtration technologies remove suspended solids, oil, and grease from completion fluids to improve operational efficiency and environmental compliance.

Innovative fluid technologies, such as the BARAKLEAN® degreaser/cleaning fluid system, and mechanical wellbore cleaning tools offer advanced solutions for complex well environments. Mechanical cleaning tools provide a physical means of removing debris and contaminants to optimize wellbore preparation further.

BaraKlean® cleaners promote wellbore cleanliness to lower costs and boost production.

Customized filtration solutions maximize filtration and ensure environmental compliance for fluid discharge.

Baroid’s breaker systems remove filter cake to improve productivity or injectivity of treated wells.

Proven corrosion-control treatments that mitigate the corrosive qualities of drilling, completion fluids, and other downhole factors.

Reduce or eliminate differential pressure across the packer with Baroid’s packer fluids, extending packer life and reliability.

Providing superior chemical performance, optimized stimulation, and on-site support through cost-effective, enhanced production flow