Search

Search

Search

Search

Operator increased oil production and generated $5.8MM in additional revenue by transitioning from gas lift to ESPs with the help of Intelevate digital platform

Download PDFProduction inefficiencies led the operator to consider ESP conversion

Delaware Basin, West Texas

An independent operator in West Texas’s Delaware Basin initially produced one of its seven wells using a jet pump and gas lift for the remaining six. However, due to unsatisfactory production rates, it decided to transition all wells to ESPs.

While gas lifts are a popular choice for artificial lift due to their simplicity and low operating costs, they eventually lead to production losses when they fail to provide optimal drawdown. ESPs offer superior production rates but require technical expertise to operate effectively.

In this case, the wells were located in a gas- and sand-prone area, which posed challenges for optimizing performance and avoiding premature failure. Without a dedicated in-house ESP expert, the operator turned to the Intelevate® digital platform and team for guidance.

The Intelevate digital platform successfully converted all seven wells to ESPs by providing tailored designs, remote monitoring, and technical expertise.

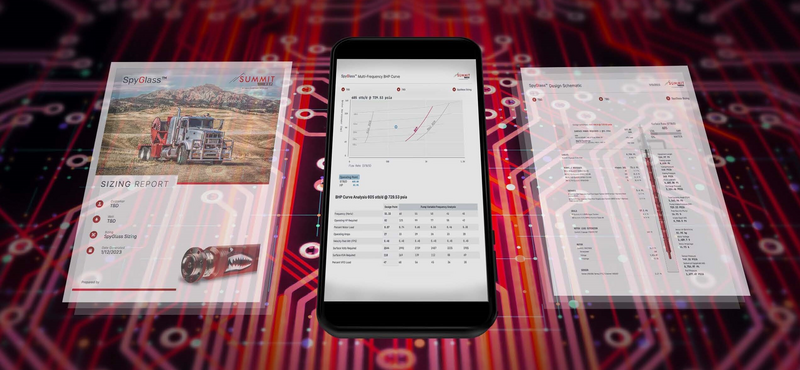

Powered by our Summit Knowledge™ digital ecosystem, Halliburton conducted 64 performance evaluations in SpyGlass™, our pump sizing software, over six months to optimize production and utilize downhole data for maximal drawdown. We made 74 speed adjustments remotely, reducing field visits.

Incremental revenue gain

Average ESP uptime

BBL production increse across 7 wells

Performance evaluations conducted

Converting the lift type and installing seven Halliburton ESPs from November to May increased cumulative oil production by 71,730 BBL across all seven wells. This additional production generated $5.8MM in revenue (calculated at $81/BOE, compared to projections using the initial forms of artificial lift.

Daily remote monitoring and technical trend analysis contributed to an average uptime of 88%. They reduced HSA hazards by eliminating the need for field personnel to make adjustments at the well site. Coupled with zero ESP failures during this period, the total cost of ownership for the operator decreased significantly. This demonstrated the superiority of ESP products over other forms of artificial lift.

The core of our digital ESP solutions integrates essential data sources and leverages advanced data science to automate workflows.

Providing improved ESP system optimization and extensive customizable well monitoring to meet all your production needs.

Cloud-based application for designing and assessing electric submersible pump performance.

Halliburton's superior performance and consistent delivery reduces time and maximizes efficiency.