Search

Search

Search

Search

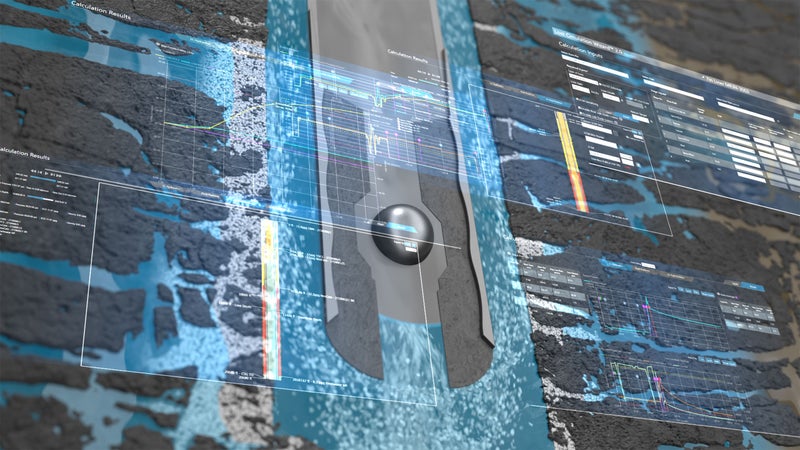

Assess and monitor critical variables before, during, and after a cement job to ensure integrity and zonal isolation

Talk to an expertIntegral to our cementing services, our cementing software suite helps energy companies solve complex challenges, reduce operational risk, and optimize production.

As wells reach greater depths and complexity, maintaining wellbore integrity becomes essential. Halliburton’s cementing software offers tools to design smarter, execute faster, and validate cement placement in real time. Whether operating in conventional oil and gas, geothermal, or carbon capture and storage (CCUS) environments, our software helps provide effective barriers across the well lifecycle.

Our software applies artificial intelligence (AI), machine learning, and digital twin technology to customize cement designs for specific well conditions. Engineers simulate fluid behavior, optimize centralizer placement, and forecast top of cement (TOC) with precision. These predictive capabilities help reduce nonproductive time and avoid costly remediation.

Operators stream and analyze up to 20 real-time variables, including pump rates, pressures, and equivalent circulating density (ECD). This enables immediate validation of cement placement and early detection of anomalies. Real-time insights improve decision-making and enhance operational safety.

Post-job evaluation tools compare execution data with design parameters to confirm cement integrity and identify improvement opportunities. Advanced modeling assesses risks such as casing deformation, fluid migration, and sustained casing pressure. These insights inform future designs and strengthen operational outcomes.

Halliburton’s cementing software suite includes:

Cementing barrier design and tailoring digital twin software that enables real-time job monitoring, evaluation, and instantaneous barrier validation.

Lost Circulation Wizard™ software allows Halliburton technical professionals to predict the optimal LCM/fluid package to mitigate losses during and after cement operations.

Evaluating LCM selection and concentration for optimal passage, suspendability, and transport.

Tailored design decisions employed by machine learning to improve the probability of operational success.

Advanced FEA analyzes the casing, cement sheath, and formation information to determine the cement mechanical properties necessary for long-term integrity.

Halliburton cementing software works as part of our complete cementing services. By combining field-proven technology with real-time analytics, we help improve well integrity, reduce risk, and support informed decisions throughout the operation.

Whether designing a new well or evaluating post-job cement performance, our software provides the clarity and confidence needed to sustain barriers for the life of the well.