Search

Search

Search

Search

Built to maximize directional performance

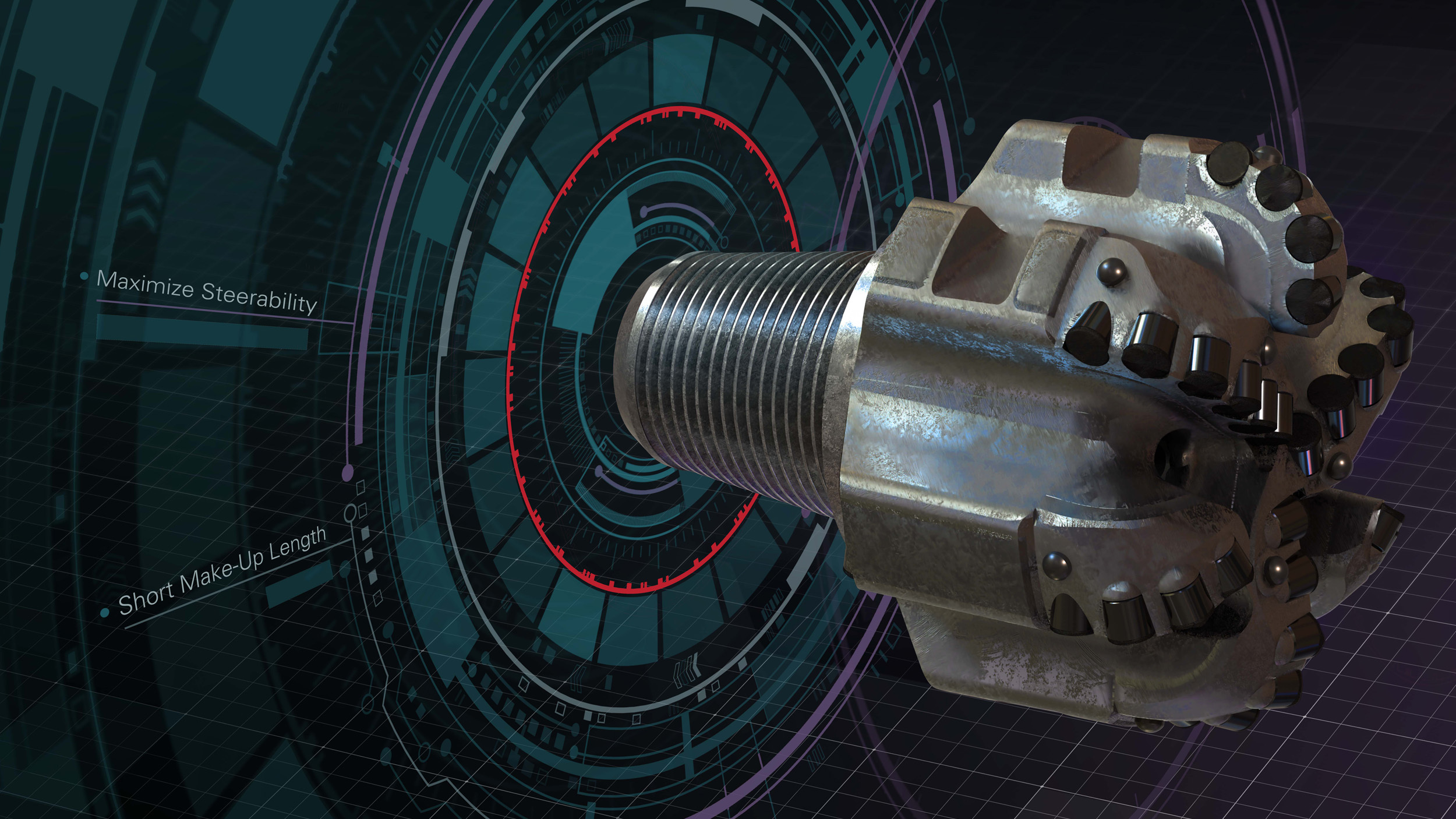

TALK TO AN EXPERTHyperSteer™ directional drill bits are engineered to deliver maximum steerability and stability for vertical, curve, and lateral applications. Designed with reduced makeup length and optimized gauge pads, HyperSteer™ helps operators to maximize directional performance, minimize drilling dysfunctions, and reduce overall well construction time.

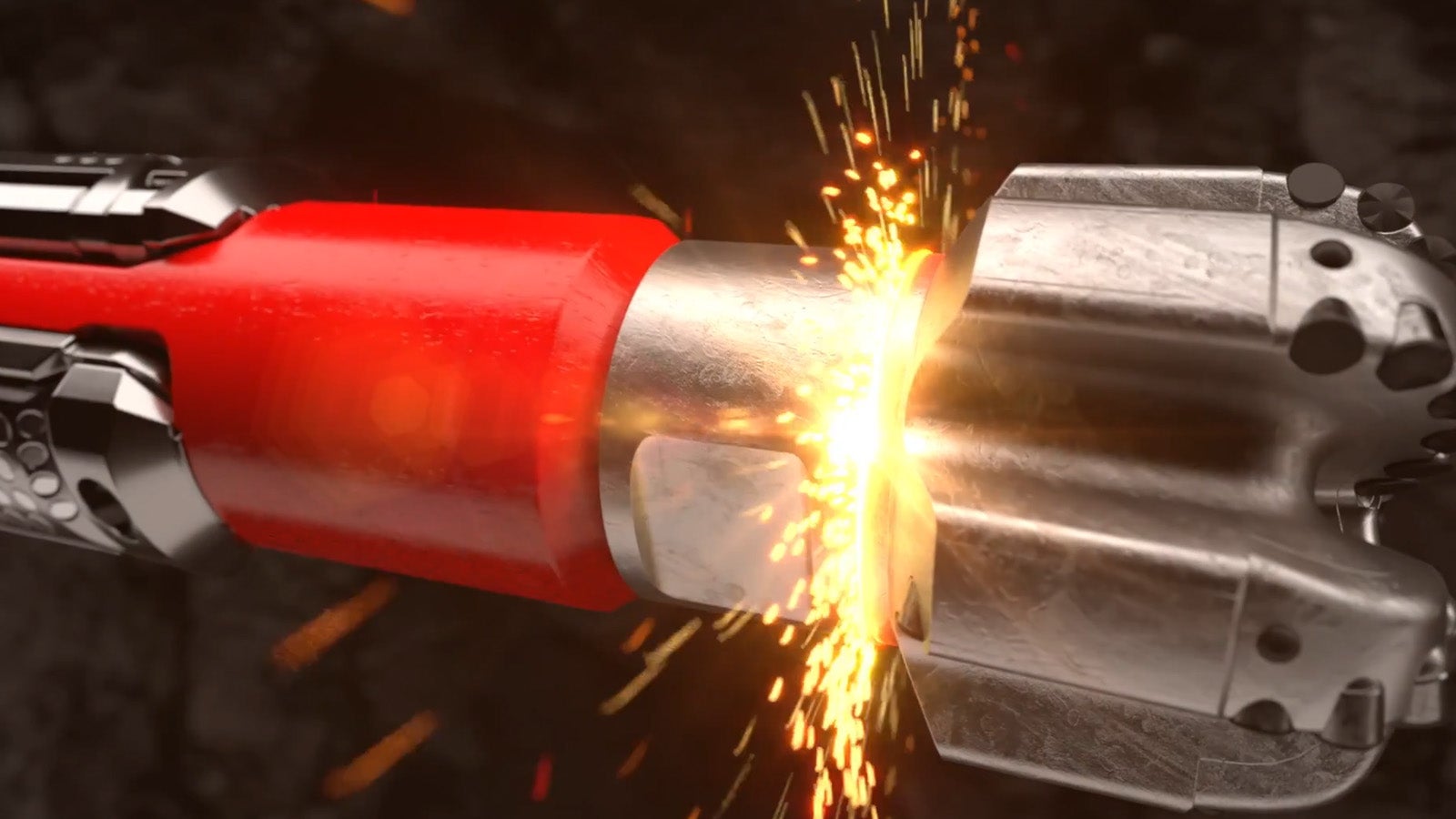

HyperSteer™ MX drill bits

The technology combines the precise steerability of HyperSteer directional drill bits with a durable matrix body.

Read announcementIt allows operators to drill longer in harsh environments and supports efforts to minimize well time and maximize directional performance for customers.

Reduced makeup length for high build rates in curve and lateral applications

0:34

Halliburton expands the HyperSteer™ portfolio with HyperSteer™ MX directional drill bits. The matrix body technology provides superior durability and directional control for demanding drilling challenges in harsh conditions.

Learn how the operator drilled their first-ever four-mile lateral in a single run, reaching a total depth (TD) of 30,315 ft

1:12

world oil / october 2023

Drilling challenges remain the same: drill faster and more efficiently. Read about how the HyperSteer™ directional drill bit and iCruise® X rotary steerable system are consistently drilling the vertical, curve, and lateral in one run.

read article

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Explore

Juggernaut® cutter technology for increased impact and abrasion resistance.

Explore

Geometrix™ 4D-shaped cutters use different geometries to optimize drilling efficiency and durability.

Explore