Search

Search

Search

Search

Improve reliability, consistency, and efficiency with integrated automation, real-time drilling parameters, and remote execution

talk to an expertDownhole conditions are becoming more complex and unpredictable. Temperature changes, vibration levels, and high-pressure environments can cause challenges, making outcomes difficult to predict.

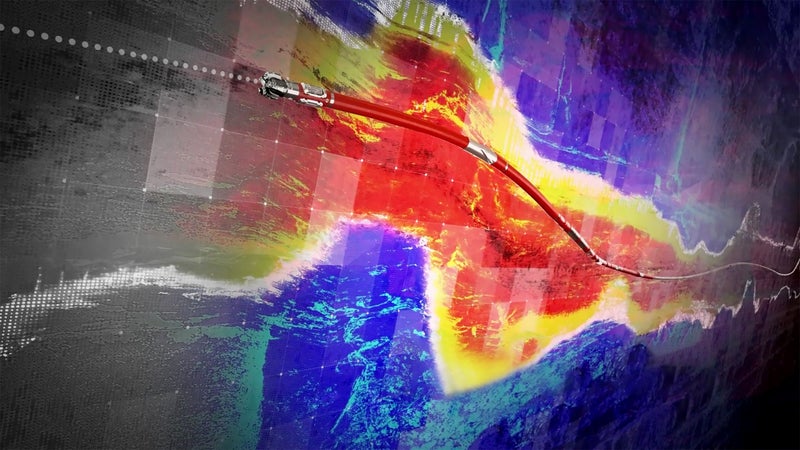

LOGIX™ automation and remote operations helps provide the insights and solutions that operators need to maximize their asset value. With real-time adaptability from machine learning algorithms and dynamic adjustment of drilling parameters, LOGIX™ automation and remote operations helps ensure optimal operations even in difficult geological formations.

The integration of downhole data with rig control systems is designed to optimize drilling efficiency and ROP, while automation reduces non-productive time and streamlines well delivery. Operators can achieve consistent, repeatable, reliable results, which can lead to shorter time to production and reduced well construction costs.

oil & gas middle east awards 2025

Halliburton LOGIX™ automation and remote operations, combined with Nabors’ SmartROS® rig operating system, form a unified platform that enables consistent, repeatable drilling performance. This recognition highlights our dedication and innovative efforts to advance automation and digital solutions within the industry.

Operators require real-time decisions for optimal well placement and wellbore quality. But miscalculations, lack of experience, or outside influences can result in inconsistent wells or safety incidents.

LOGIX™ drilling automation incorporates industry-forward technology like digital twins and machine learning to steer without human intervention. Autonomous drilling parameters and well path adjustments help ensure the wellbore stays within the desired target. Integrated drilling dynamics mitigate vibration while drilling, and collision avoidance provides monitoring and alerts. You achieve:

Advanced technologies, sophisticated algorithms, and downhole data used in the well placement control system allow operators to react quickly to changing downhole conditions. This results in more precise well placements because the platform autonomously adjusts drilling parameters and/or the well path. The reduction in downtime increases efficiency. Continuous downhole environment updates deliver repeatable, more accurate well positioning outcomes.

Drilling automation, real-time adaptability, and data-driven optimization provided by digital twins improve drilling performance and mitigate vibration. Machine learning algorithms can increase ROP significantly as they adjust drilling parameters for optimal performance. The LOGIX™ system also reduces downtime through bit wear prediction and failure-related trip reduction.

Real-time sensor data and advanced hydraulic models predict precise wellbore hydraulics, maintain wellbore integrity, and manage wellbore pressure. The wellbore integrity hydraulics applications help provide better formation pressure control, influx management, and wellbore stability insights to optimize ROP, tripping speeds, and well integrity.

Gain a comprehensive view of your operations with real-time visualization of surface and downhole data. The advanced algorithms available in our analytics and visualization solutions detect events and provide timely alarms for rig personnel or remote center staff.

Our integrated solutions remotely control Halliburton surface equipment, which improves efficiency across cementing, wireline services, and drilling activities while integrating with the rig control system. Operators gain real-time insights, streamlined processes, and optimized performance to help ensure seamless and efficient site operations.

Rig automation and remote operations require effective real-time communication between the rig and the office. Our data exchange solutions provide seamless connectivity and real-time insights through the integration of multi-well data in the cloud. The data is then transmitted to Halliburton experts, customers, and third parties for faster, more informed decision-making.

LOGIX™ automated geosteering redefines geosteering precision through automation, real-time intelligence, and advanced geological modeling to optimize well placement and maximize recovery.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Remote controlled, autonomous offshore cementing for operational efficiency and consistency.

Real-time data and AI-driven models provide insights into equipment readiness that help increase reliability, efficiency, and barrier execution consistency.

Real-time virtual logging system for faster, better data-driven decisions.

Drill wells safely, avoiding financial and environmental damages from anti-collision situations.