Search

Search

Search

Search

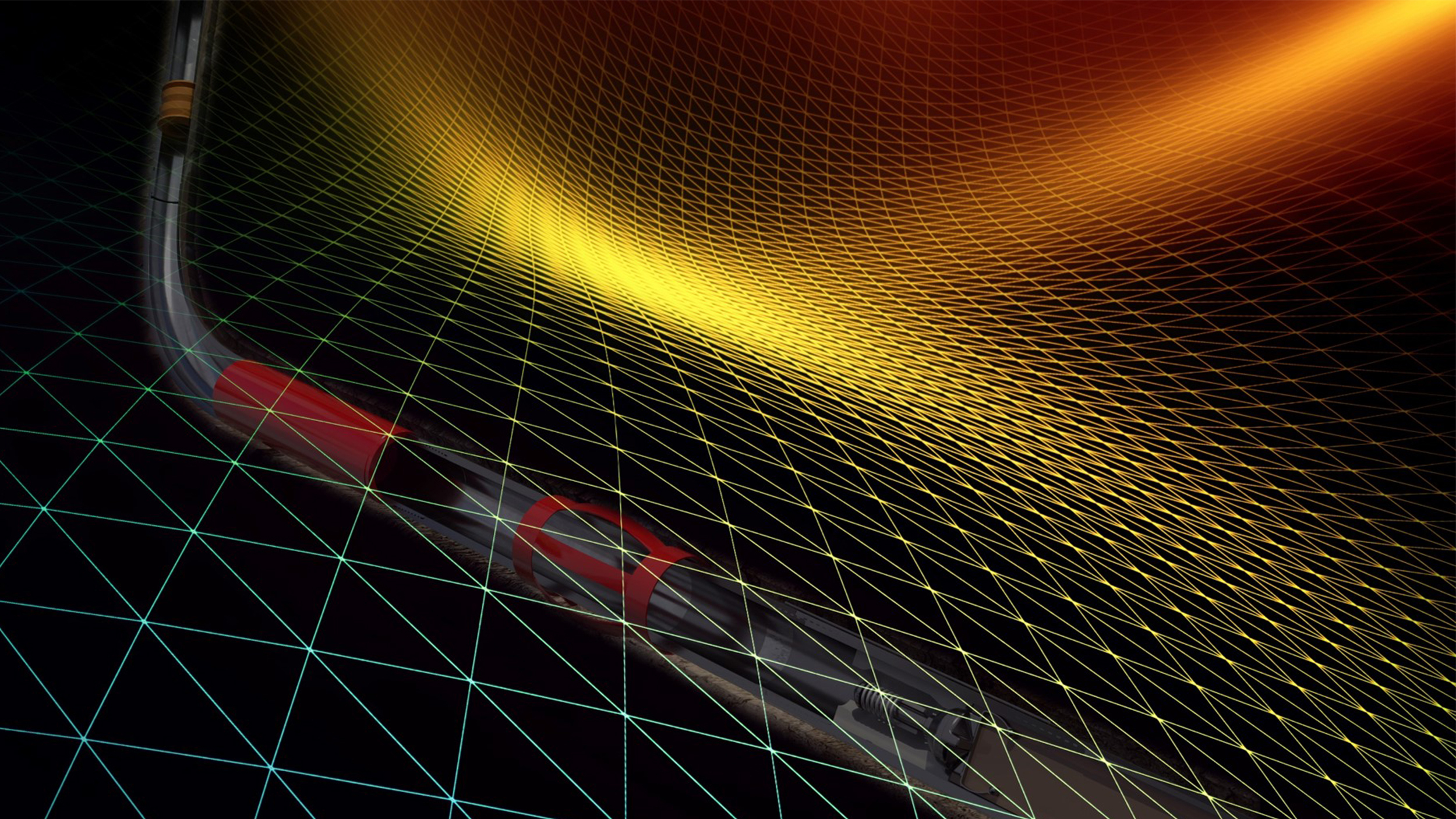

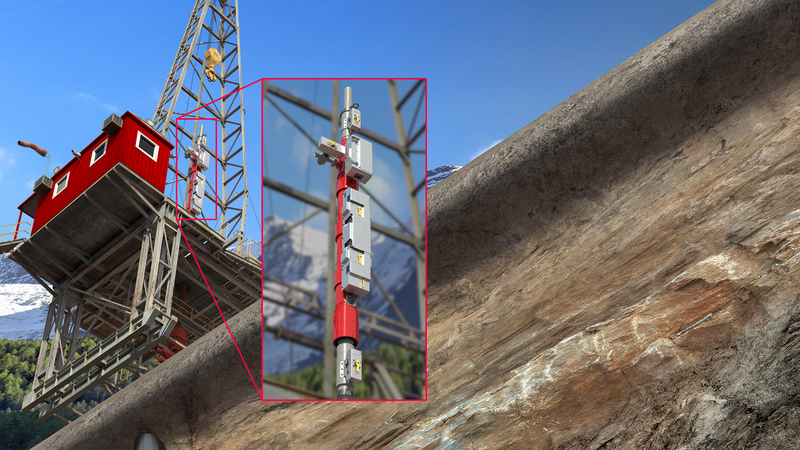

Engineered casing equipment solutions to help run and land casing to depth, ensure proper centralization, and achieve long-term zonal isolation

Talk to an expertThe Halliburton approach to casing equipment product design and delivery helps provide a full set of casing equipment solutions that can be tailored to your specific well needs, so your project runs on time and on budget.

Our casing equipment portfolio goes through rigorous testing, in some cases above and beyond API specifications, to provide reliable performance for each solution. Halliburton casing equipment can help operators run and land casing to total depth faster, ensure proper centralization for a better cement job, relieve rig strain, and provide effective isolation to prevent sustained casing pressure.

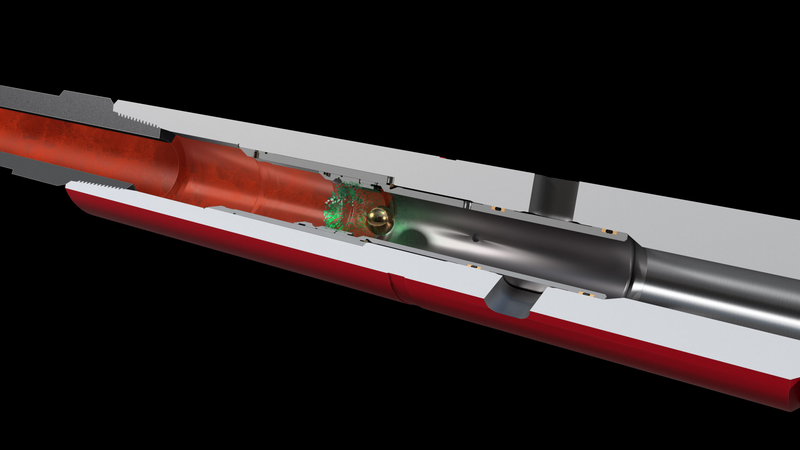

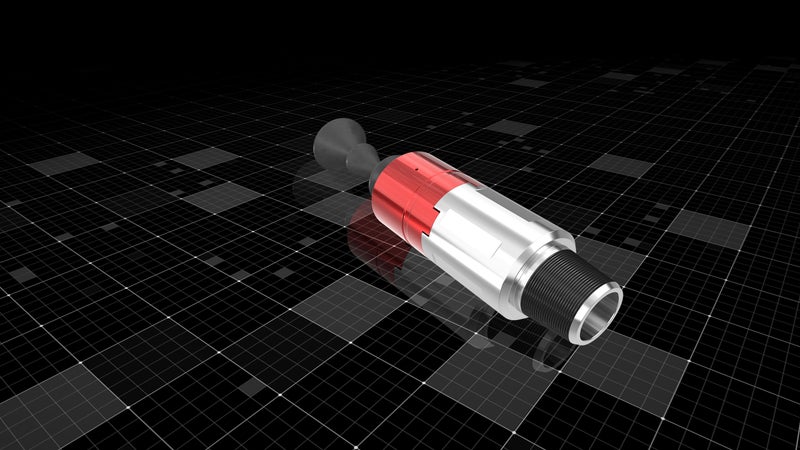

Discover the SuperFill™ II diverter, a cutting-edge solution for auto-fill float equipment designed to reduce surge pressure and improve casing run efficiency.

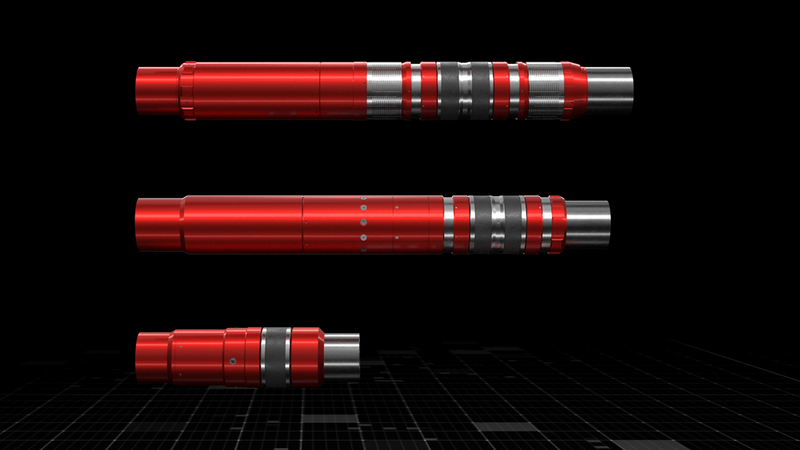

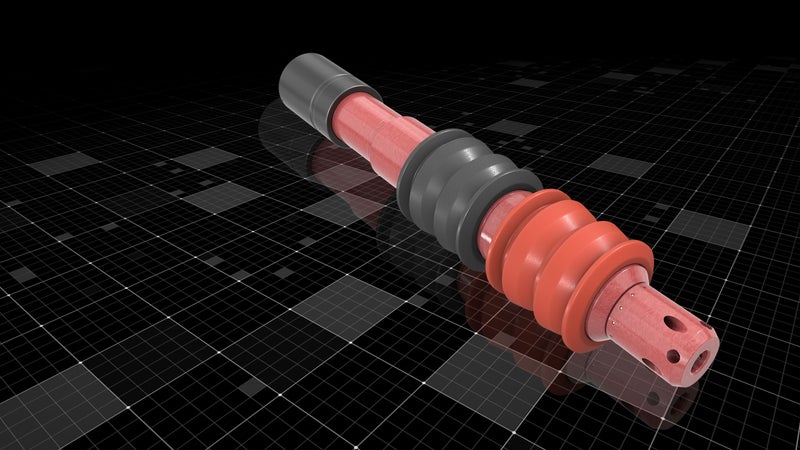

The Obex® family of compression-set packers provides a range of reliable, mechanical barrier support to achieve effective zonal isolation.

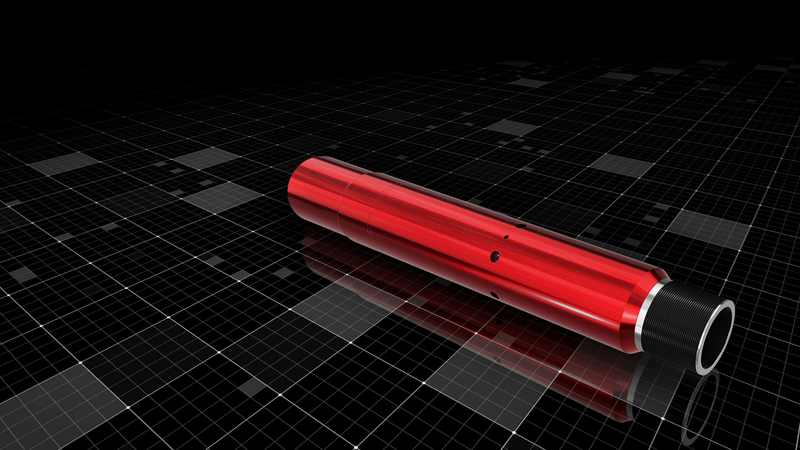

The Fidelis™ stage cementer provides multiple stage cementing capabilities with hydraulic fracturing durability.

The NO-Dull™ cementer is a fully composite system that enables a damage-free drillout and reduces drillout time during multiple stage cementing operations.

GasVault™ float valves provide a gas tight mechanical barrier designed for a safer wet-shoe track.

Protech™ II centralizers reduce friction, enhance flow area, and keep positive standoff.

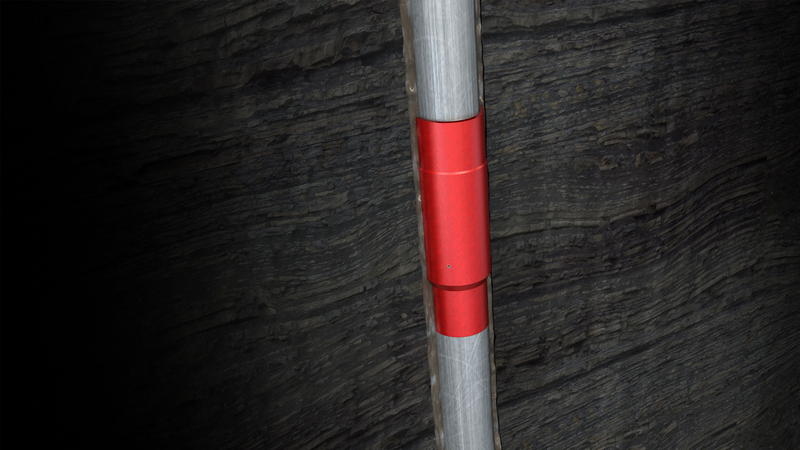

RED-X™ single-piece centralizers outperform competing designs with higher run speeds and greater efficiency gains in multiple well types.

Overcome excessive drag forces to run casing to depth with the AirGlide® floatation collar.

Enabling rotation and reciprocation to improve cement coverage to reduce communication between frac stages and maximize asset value.

Designed for offshore operations to surface launch balls or darts in order to operate subsea plug sets and associated tools.

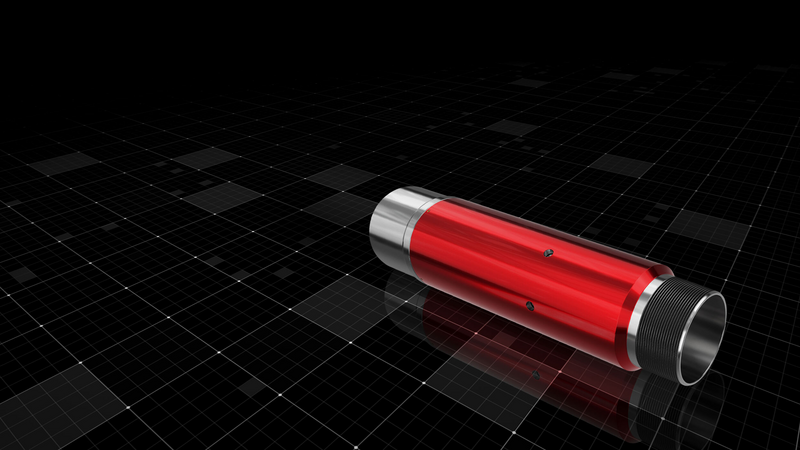

The SuperFill™ family of float equipment is designed to help reduce the effect of surge pressure to optimize casing running speeds.

SSR-II™ cement plugs are designed to provide mechanical separation and prevent contamination between cementing fluids pumped down the landing string.

The Halliburton BHKA™ plug setting disconnect tool simplifies cement plug placement when necessary during well construction or abandonment operations.