Search

Search

Search

Search

Improve speed and accuracy with our complete services

Talk to an expertHalliburton offers comprehensive well-intervention solutions, from basic completion tasks to advanced operations. Our slickline services help maintain production and monitor downhole conditions. They ensure wells function properly without complex and expensive equipment like workover rigs or coiled tubing units.

Our slickline capabilities include:

Drawing on over 75 years of expertise, Halliburton delivers customized solutions for complex well challenges to help ensure optimal performance, cost efficiency, and maximized asset value.

Slickline services offer substantial operational advantages for well intervention. They provide a cost-effective solution requiring less equipment and personnel compared to workover rigs or coiled tubing units.

Rapid deployment enhances time efficiency, reduces downtime, and boosts operational performance, minimizing production interruptions and allowing for quicker, more efficient interventions.

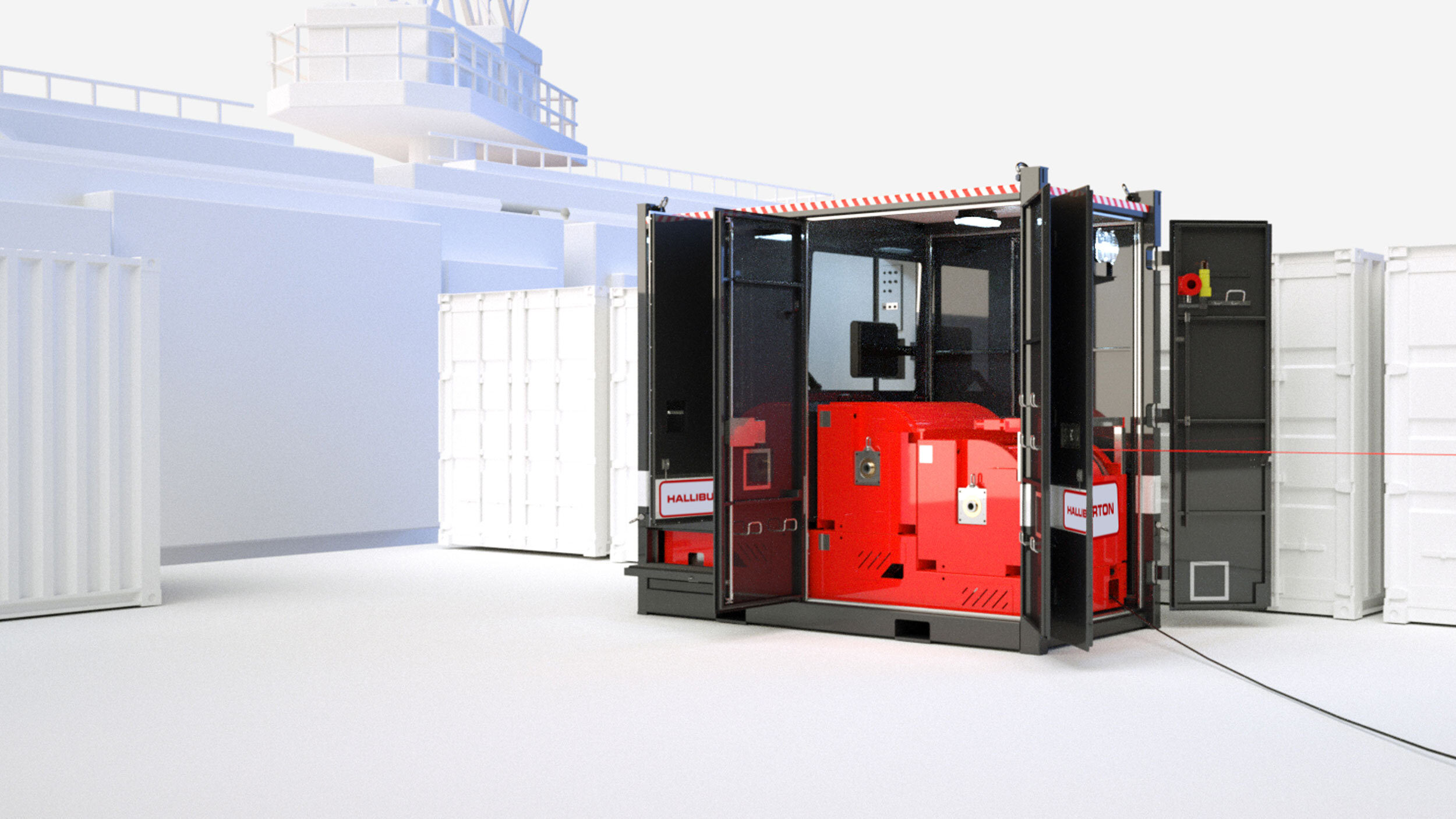

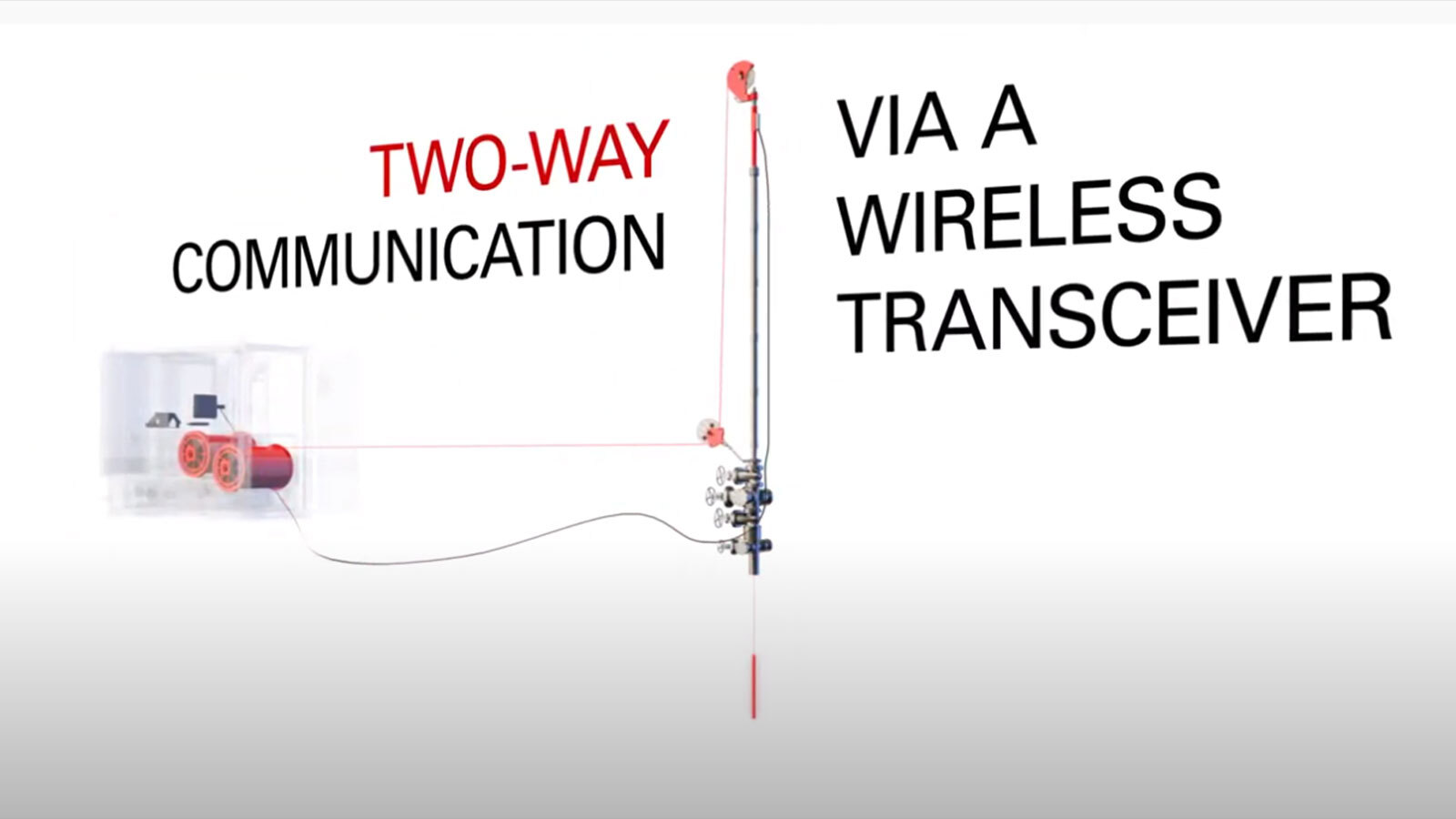

Halliburton's digital slickline services, known as RELAY™, enhance well interventions with real-time downhole communication for logging and mechanical services. This system offers bi-directional communication, allowing real-time depth correlation, formation evaluation, production logging, perforating, and pipe recovery.

The RELAY digital slickline system helps improve well-intervention efficiency, reduces uncertainty, and minimizes environmental impact. It also aids in making informed downhole decisions, increases safety, and reduces logistics costs.

explore relaySlickline is essential for well intervention and maintenance, performing tasks such as cleaning, repairing, and maintaining wells to ensure optimal production. It also plays a key role in logging and data acquisition, measuring and recording downhole conditions to provide valuable data for reservoir evaluation and management.

Another critical application is setting and retrieving downhole tools, including packers, plugs, and valves, to ensure proper well function. Additionally, slickline is vital in plug and abandonment operations, isolating and sealing off depleted or non-productive zones to help ensure environmental safety and regulatory compliance.

RELAY digital slickline services improve intervention efficiency, reduce uncertainty, and minimize environmental impact with real-time down-hole connectivity.

Halliburton has a range of pipe-cutting and hole-punching technology and applies the best mix of tools and methods for well and pipe-cutting challenges.