Search

Search

Search

Search

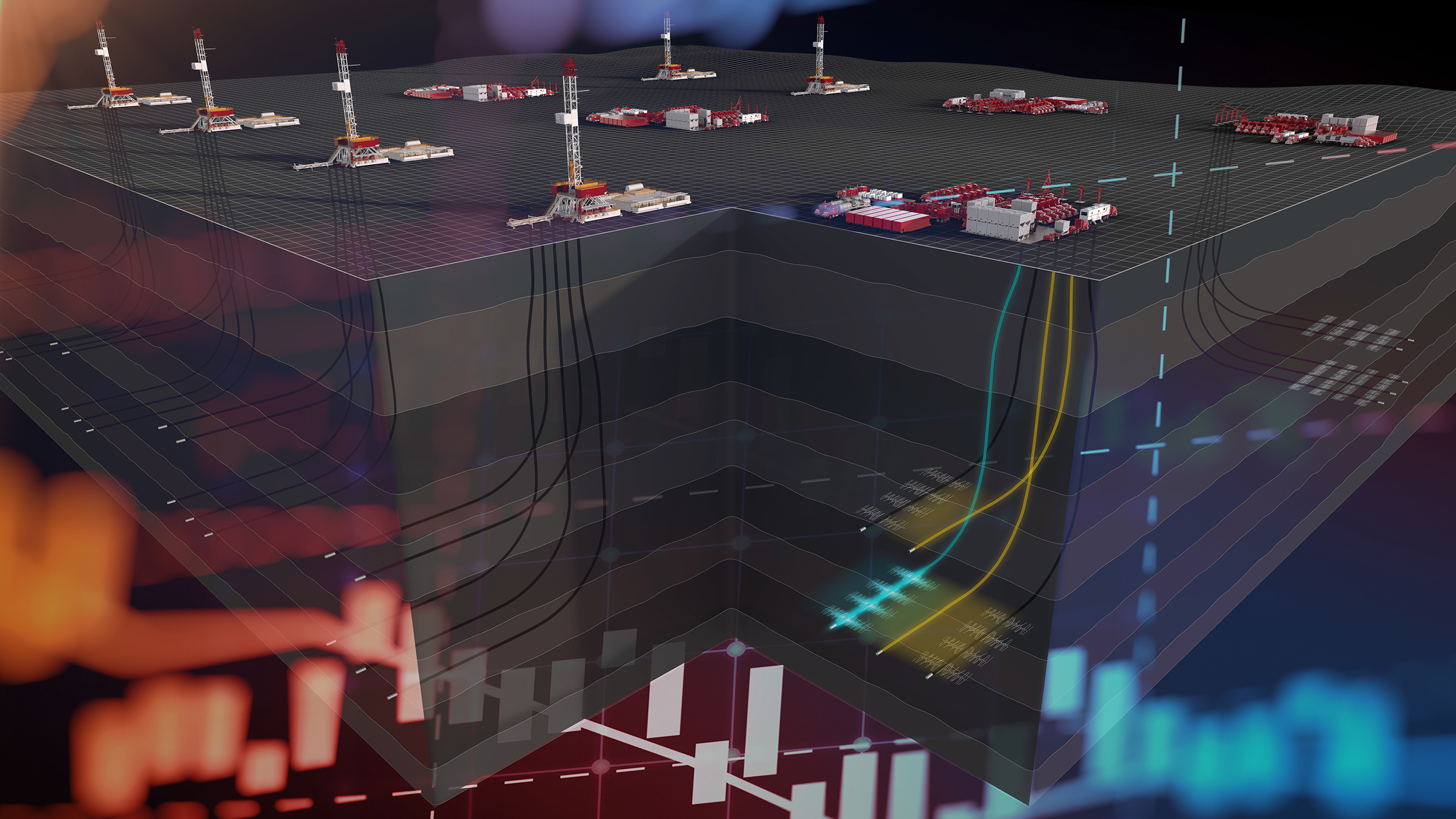

Enabling low-cost, high-quality routine cross-well monitoring for more wells across your asset

Talk to an expertToday, fiber optic fracture monitoring provides valuable insights that help operators understand and validate fracture performance. However, for many operators, the historical cost and complexity of incorporating fiber at scale is simply not economically feasible. To provide fiber solutions that operators can use routinely in every well, Halliburton has engineered cost and complexity out of fiber optic fracture monitoring.

ExpressFiber disposable fiber cable is the newest addition to our scalable fiber portfolio that provides a direct measurement of well interference—at a price point comparable to tracers and indirect pressure analysis.

ExpressFiber is run in offset wells to acquire direct measurements of distributed acoustic sensing (DAS) microseismic, strain and temperature. In addition to being able to install this fiber on existing wells in a few hours, this disposable, low cost fiber makes cross-well monitoring a routine service you can benefit from in every well on your pad, across your entire asset.

When all you want is to better understand frac hits, fracture growth and interactions, ExpressFiber is the economic, risk-free fiber optic option for cross-well monitoring.

Routine cross-well monitoring

Halliburton introduces ExpressFiber, a single-use fiber optic cable that offers accurate, direct cross-well measurements, at a price point that enables fracture monitoring on every well pad. ExpressFiber is the most economic fiber solution for routine cross-well monitoring, has little to no impact on operations and can be pumped downhole in offset wells within a couple of hours.

Read AnnouncementFootage Deployed

Tools Deployed

Stages Completed

Frac Hits Observed

Because its disposable, this single use fiber eliminates any concerns of damaging the cable during fracturing. ExpressFiber can be pumped down hole at any point in time before or during the fracturing operation.

This means you now have the opportunity to monitor cross-well interactions on already drilled wells. If at any time the cable is damaged, another fiber can simply be pumped down to replace it. There is no need to halt operations to remove the fiber, as the amount of space it takes up is equivalent to a pound of proppant.

This disposable fiber can be deployed in extended-reach wells up to 30,000 feet and withstands downhole conditions for the duration of the stimulation before degrading and exiting through perforations.

Just because it’s disposable, doesn’t mean its low quality. Disposable fiber is bare fiber, meaning there is no outer protective layer, making it more sensitive. ExpressFiber acquires high quality strain, microseismic and temperature data, only at a significantly lower price.

ExpressFiber is run downhole to enable our SensoriTM Cross-Well fracture monitoring service. This service provides insights that help you understand fracture growth to prevent communication and improve capital efficiency.

Sensori Cross-Well allows you to pinpoint cross well interference by using strain and DAS microseismic measurements. Analytics include treatment volumes, growth over time, and azimuth for a detailed picture of how and when connection of offset wells are established. With a single sensor detecting multiple measurements, you now have the ability to understand how fracture uniformity is impacting offset wells. Sensori Cross-Well also confirms communication across different benches, allowing you to monitor the frequency and severity of communication across multiple intervals.

With ExpressFiber, you can start recording cross-well data in a few hours, from the time of pump-down to pressing record.

All the equipment you need to install is already on site, and it’s as simple as dropping the fiber down hole and pumping it out to the toe. Once the fiber is in the wellbore, it’s hooked up to the interrogator unit and recording begins.