Search

Search

Search

Search

Halliburton perforating solutions offer industry-leading technologies, tools, and techniques with unequaled success and safety

Talk to an expertThe award-winning Halliburton Advanced Perforating Flow Lab (APFL) at the Jet Research Center® (JRC) Perforating Center of Excellence helps operators understand and optimize perforating system performance in diverse downhole conditions. It provides real-world answers that account for overburden stress, reservoir pore pressure, wellbore pressure, and reservoir and wellbore response. The APFL also identifies the optimum solution to connect the wellbore and reservoir.

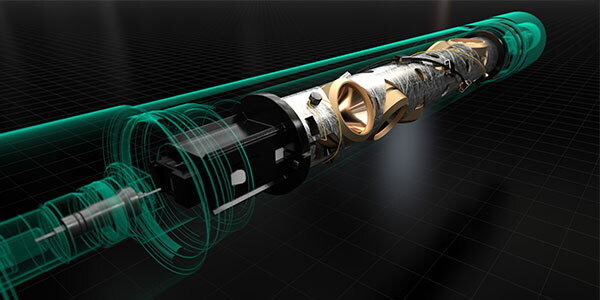

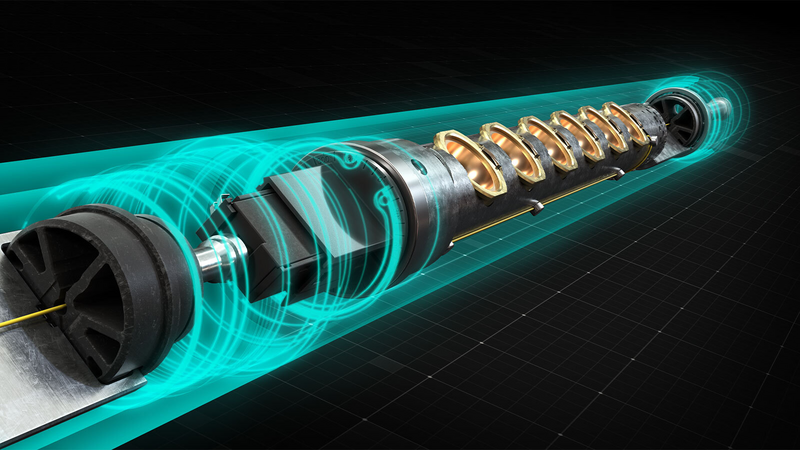

Velocity perforating gun system’s modular design provides safe, efficient, and reliable operations.

Velocity Revolve+™ guns are the industry's most accurate, compact, and versatile system for orienting perforations in fiber-optic completions.

Economic, compact, and versatile system for orienting perforations in horizontal wells.

The system helps ensure that debris created from shaped charges is minimized, containing larger debris pieces within the gun system for safe, clean perforating without sacrificing flow area.

The G-Force system enables perforating in any direction regardless of gun/casing positioning.

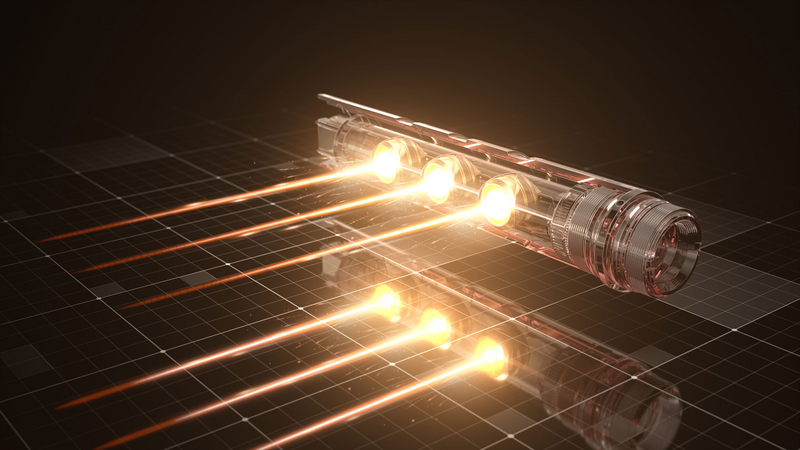

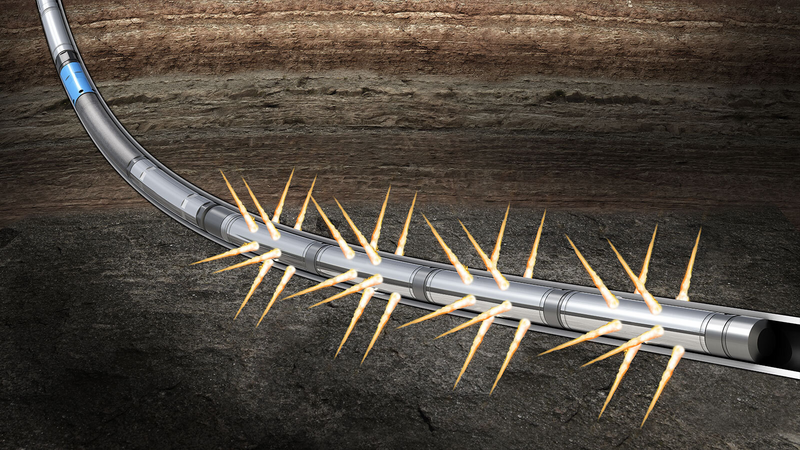

JRC designs and manufactures a wide range of shaped charges for perforating, including deep penetrating, fracturing, and big hole solutions.

Perforate with the original consistent hole size charge designed for fracturing.

MaxForce FLOW maximizes perforating flow area in large-ID casing strings.

RockJet™ shaped perforating charges provide the deepest penetration in actual downhole stressed rock and maximize casing hole size to deliver the greatest possible well performance.

Flexible and reliable triggering options designed for challenging and complex wells.

The Halliburton MaxFire® electronic firing system (EFS) has numerous built-in features that enable explosive tools to be deployed and initiated safely.

Safe, reliable solutions for pipe recovery and plug and abandonment

Halliburton’s propellant-based tools delivers precision performance for punching, cutting, and ablation—without risks of detonation, debris, or shock loading.

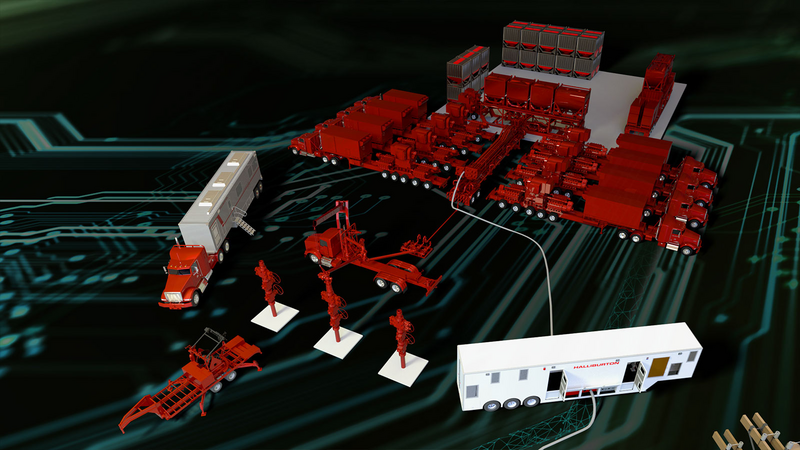

OCTIV Auto Pumpdown service controls fluid pumps and a wireline unit as a single, fully automated, closed-loop system to maximize plug and perforating performance.

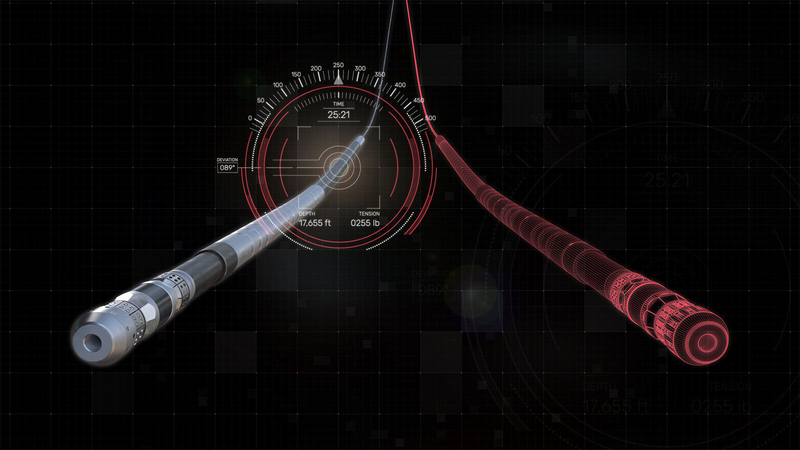

Increase pump-down perforating operational consistancy and efficiency with real-time downhole and surface data.

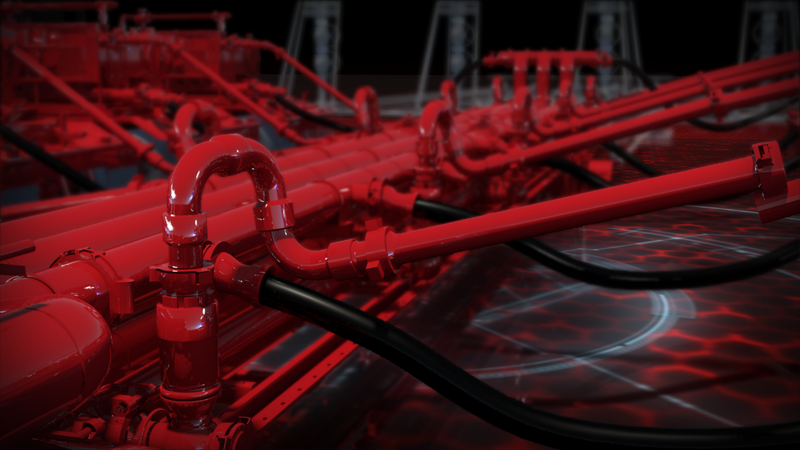

Reducing rig-up time and complexity, resulting in a more efficient, safer fracture operations.

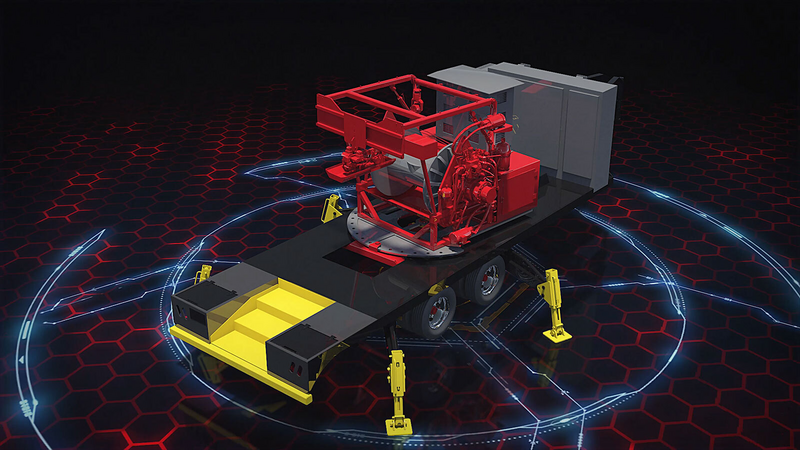

All-electric system that can be remotely operated for safety and efficiency

With the RELAY digital slickline system, you can improve well intervention efficiency, reduce uncertainty, and minimize environmental impact.

Halliburton perforating solutions are conveyance independent, meaning we can transport perforating systems to depth in diverse downhole environments via jointed pipe, wireline, slickline, RELAY Digital Slickline, or coiled tubing depending on need. Conveyance flexibility simplifies operations, leading to optimized solutions that keep logistic requirements at a minimum and create a smaller footprint.

Conventional Wireline / Slickline and pump down solutions to maximize reliability and wellsite efficiency

The RELAY Digital Slickline system is the new intelligent conveyance for well intervention operations from Halliburton. This advanced technology combines the versatility and efficiency of traditional slickline with the real-time data streaming capability of electric line.

Tubing-conveyed perforating technologies provide a total completion solution, enabling the perforation of long intervals using large pressure differentials, and allowing vertical and horizontal intervention using a wide range of perforating technologies.

Flexible perforating solutions for well intervention operations in vertical, horizontal, highly deviated, and live wells.

Halliburton’s engineered approach to perforation modeling improves the understanding of what's going on downhole, from perforation performance to tubing movement, shock loading, and wellbore pressure response during well intervention. Dynamic modeling is a powerful design tool that creates comprehensive, fit-for-purpose perforating strategies for downhole environments, well designs, and completion objectives.

SS3D™ ShockSim modeling software

Developed to simulate the 3D transient shock response of the bottomhole assembly and wellbore to conduct unique and complex failure analyses.

Jet Research Center’s Explosive Products Center is a fully integrated research, engineering, testing, and manufacturing plant. Engineers, designers, and technicians follow the American Petroleum Institute’s (API) Recommended Practice for the Evaluation of Well Perforators (RP19B) standards to produce advanced perforating systems and specialty explosive devices for the oilfield.

Located at the JRC Explosive Products Center, the APFL offers standard API RP19B and expanded testing capabilities to satisfy client testing needs.