Search

Search

Search

Search

Halliburton offers an extensive portfolio of service packers with customized options for remedial, maintenance, suspension, and isolation operations.

Talk to an expertHalliburton is the industry’s leading provider of retrievable service tools designed for wellbore isolation, testing, treating, cement squeeze, and plug and abandonment (P&A) operations.

Our testing and treating systems and custom tool combinations enable you to test well integrity and run multiple operations in a single trip, saving you rig time and money.

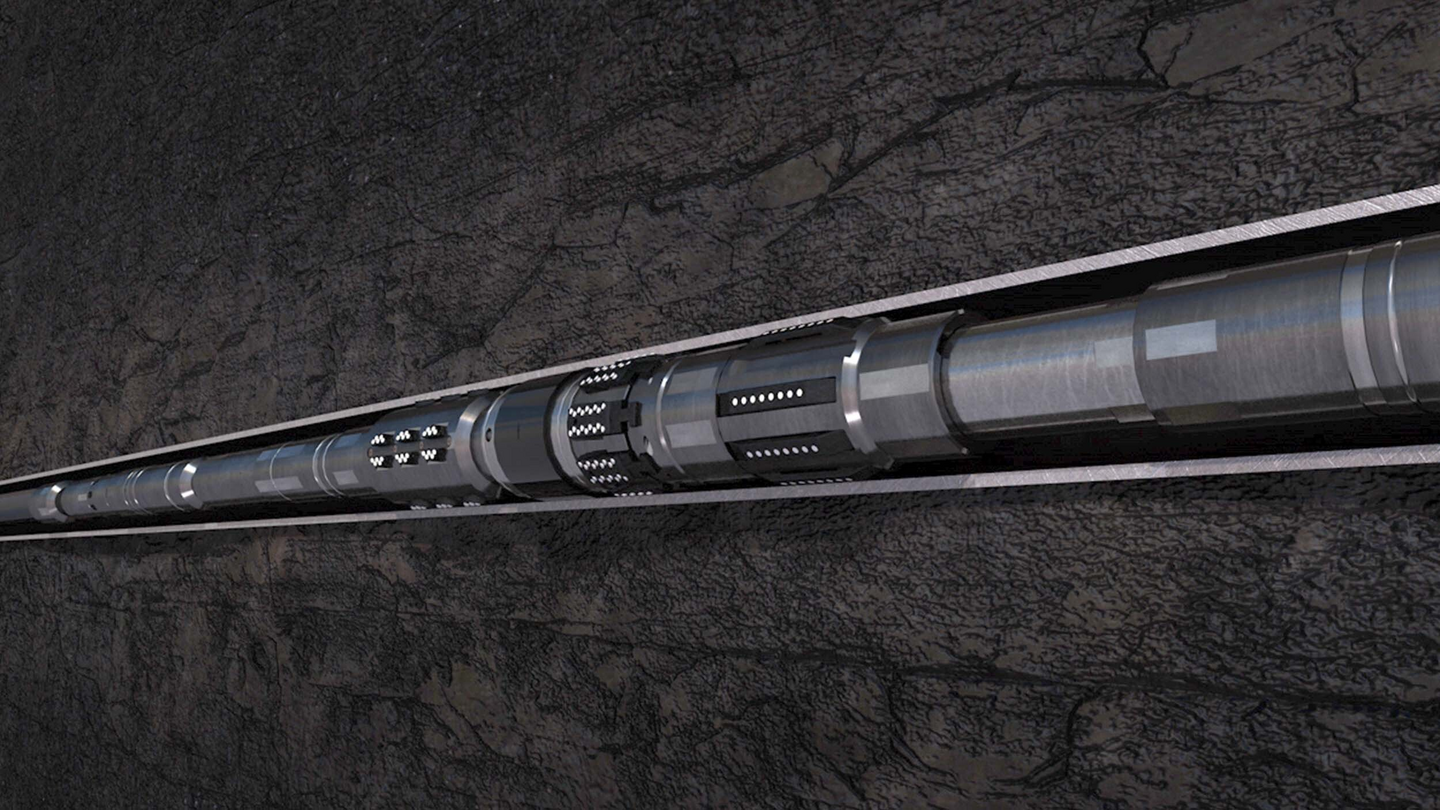

Using Halliburton service packers for zonal treatment procedures, such as high-pressure acidizing, fracturing, perforation washing, and squeezing, extends the economically viable life of your well.

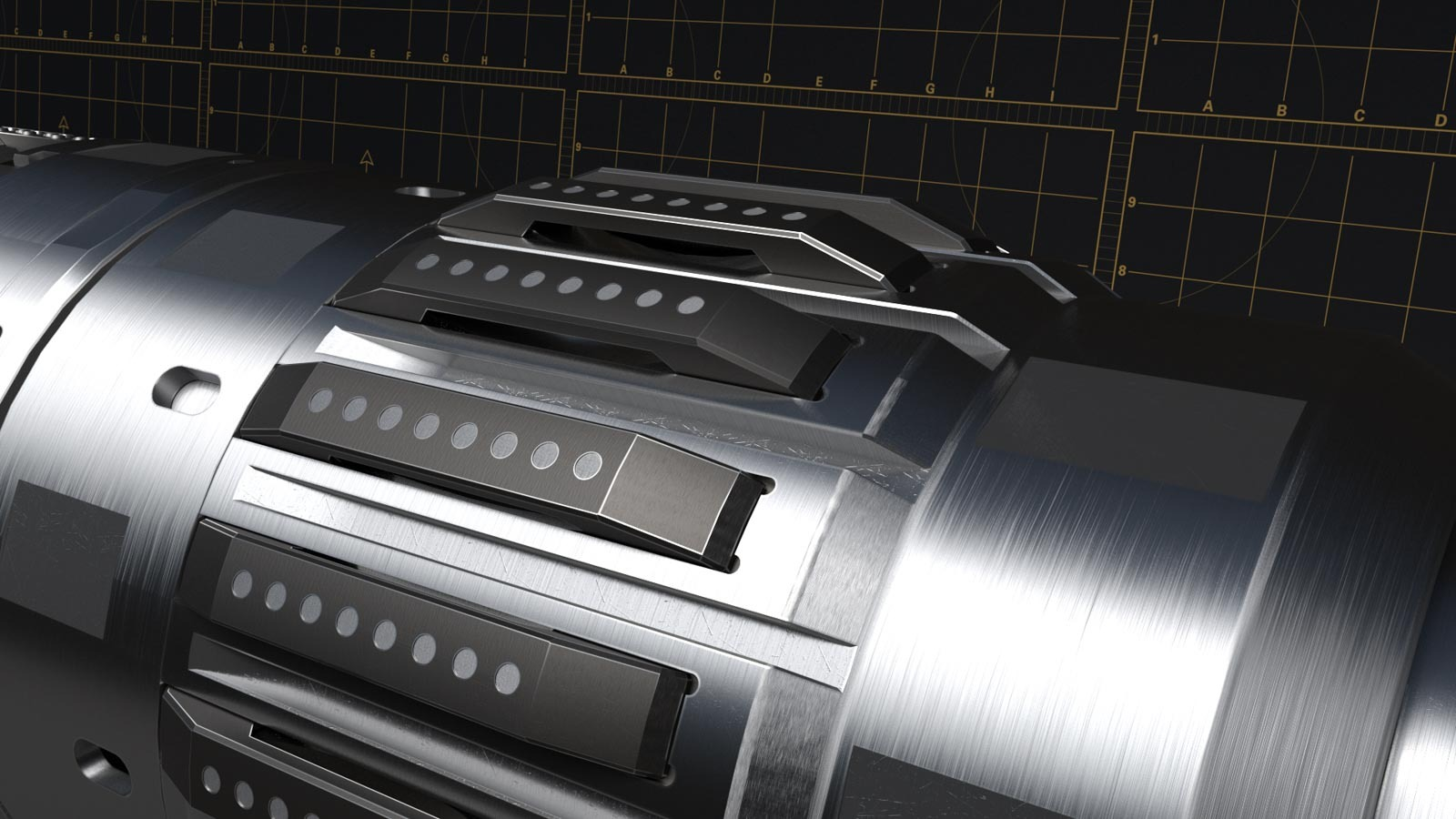

The Halliburton RTTS® Pro V3 Packer is our premier large bore well abandonment solution.

00:38

Offshore

Integrated well intervention solution saved Canada operator 20 hours of rig time equivalent to $300k.

Read case studyHalliburton maintains strict quality assurance and quality control (QA/QC) standards and processes and procedures to help ensure equipment excellence and dependability, and flawless execution.

Well-known in the industry for more than 60 years, this service packer has been run in over 100,000 jobs worldwide. Its reliability and durability is why operators ask for RTTS packers by name — some are still in wellbores that have been working continuously for as long as 30 years. For wellbore barrier applications, the RTTS packer is run with a subsurface control (SSC) valve.

Robust and field-proven design, the packer features a full-opening and hookwall used for well suspension, testing, and treating operations. The packer is qualified to API 11D1/ISO 14310 Grade V3 requirements and can be unset and retrieved by simply moving the workstring upward.

18-in. large bore well suspension and well abandonment solution, qualified to API 11D1/ISO 14310 Grade V3 requirements. A rugged element design provides excellent sealing and ability to reset the packer multiple times.

CHAMP® V 15K Non-Rotational Retrievable Packer

Ideal for deepwater, extended-reach (ERD) applications where achieving sufficient torque downhole to manipulate the toolstring can be challenging. Rated up to 15k psi and 400⁰F, the packer can pass through tight spots, allowing for its sealing elements to remain in place.

CASE STUDY

The RTTS® packer and SSC I valve combination remained undamaged inside the well for over nine years despite Hurricane Rita destroying the rig.

CASE STUDY

An operator successfully ran the bottomhole assembly with the help of an RTTS® packer, eliminating an extra downhole trip and saving thousands.

Read case study