Search

Search

Search

Search

Hybrid permanent magnet motor achieves unmatched efficiency in challenging, gassy, and unconventional well

Download PDFOperators need a motor that can withstand harsh conditions

Texas

In the challenging landscape of unconventional wells, operators face steep decline curves and the damaging effects of gas and sand production on electric submersible pump (ESP) systems. These dynamic conditions demand adaptable solutions that extend runtimes and address power cost and sustainability concerns.

While commonly used, traditional induction motors are relatively inefficient compared to PMMs. However, PMMs in these volatile environments often struggle with synchronization issues with surface motor controllers, leading to potential catastrophic failures. Operators need a motor to withstand these harsh conditions without compromising performance or reliability.

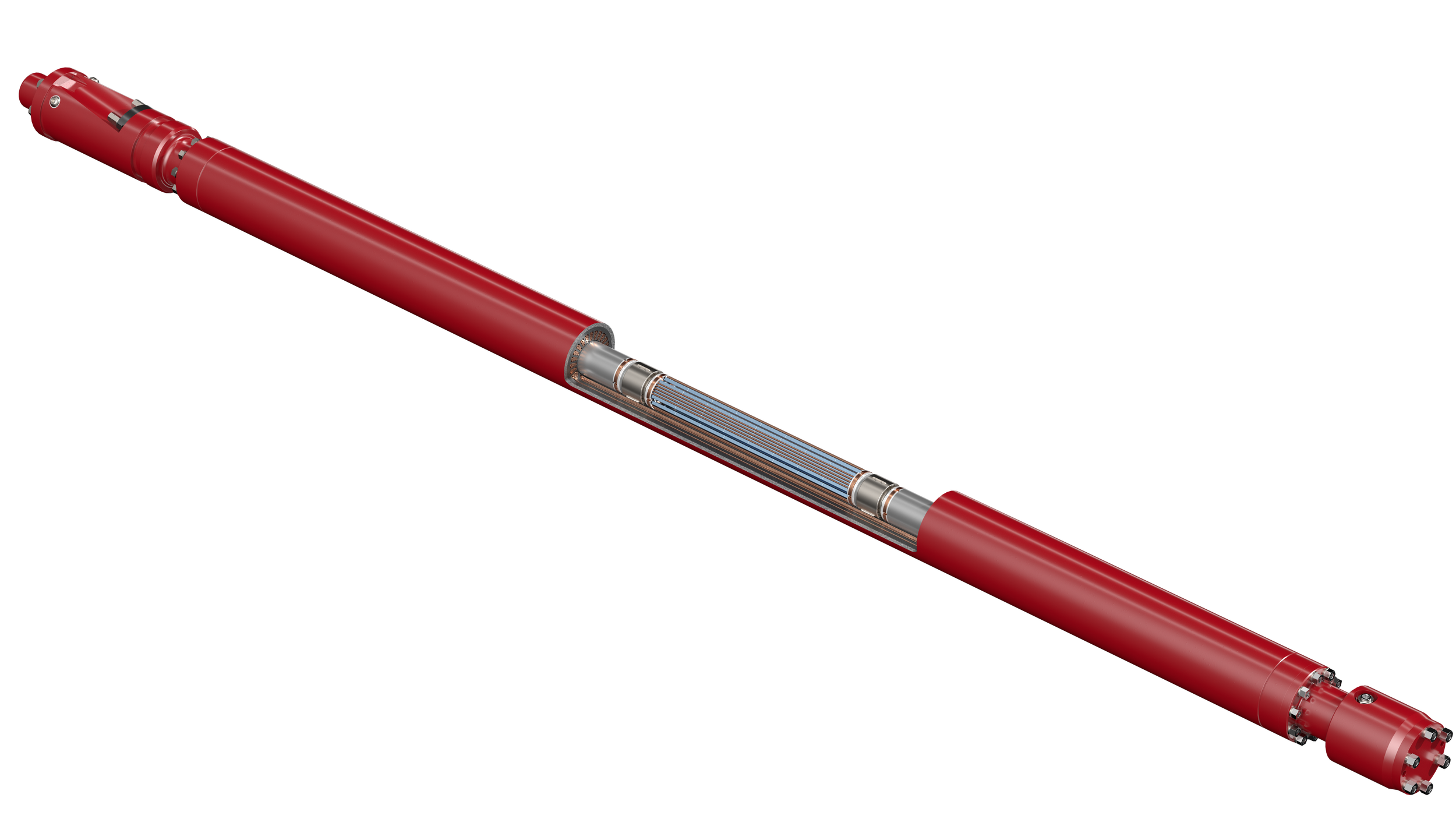

The TrueSync hybrid PMM is a groundbreaking motor that seamlessly integrates rotor bar elements from induction motors to counteract the life-limiting effects of transient torque caused by gas production or slugging. By combining the strengths of permanent magnets, the TrueSync Hybrid PMM achieves full synchronicity, delivering unmatched efficiency, enhanced stability, and prolonged operational life.

Runtime increased

Efficiency gains

Potential four-year power savings for 1,000 wells

Remote monitoring available

For one operator in West Texas, the TrueSync hybrid PMM significantly transformed their operations. In a particularly gassy, unconventional well, the motor increased runtime by five times compared to the competition. Lab tests further showcased a 20% efficiency gain over traditional induction motors. For an operator managing 1,000 production wells over a typical four-year cycle, this translates to power savings exceeding $250 million.

Corsair motors deliver long run times with greater reliability by actively resisting temperature and deformation in the harshest conditions.

Providing improved ESP system optimization and extensive customizable well monitoring to meet all your production needs.

The core of our digital ESP solutions integrates essential data sources and leverages advanced data science to automate workflows.