Search

Search

Search

Search

Corrosion resistant annular barriers and digital solutions that enable the construction of carbon capture storage wells.

Contact UsCementing a CCUS well is challenging because CO2 in the presence of water can produce carbonic acid. Conventional Portland cement degrades in the presence of carbonic acid, potentially leading to a loss of well integrity. In CCUS well construction, it is critical to design for traditional operational parameters, such as downhole temperatures and pressures.

Halliburton has decades of experience in corrosive environment barrier design. We tailor our technologies to meet the unique challenges required to achieve superior wellbore integrity in a range of CO2 environments. Risk mitigation is achieved with non-Portland cement designs, modified cement systems, or reduced Portland solutions, along with advanced well integrity software modeling.

Barriers that completely remove components that react with corrosive environments and reduce possible pathways for gas or fluid to enter the cement sheath over time.

Resin modified Portland barriers combine Portland cement and resin to provide a corrosion resistant cement sheath with enhanced elasticity and shear bond and lower permeability compared to conventional Portland systems.

Barriers tailored with additives that help lower permeability and reduce corrosion alteration in comparison to conventional Portland cement designs.

CCUS Blog

Cement barriers in carbon capture and sequestration operations face unique challenges due to the corrosive environment, harsh injection cycles, and the length of storage requirements. The right materials can help promote long-term, well integrity.

read blogCase Study

Learn how WellLock® resin provided a corrosion-resistant barrier and delivered excellent zonal isolation in the United Arab Emirate's first CO2 injection well.

Read case study

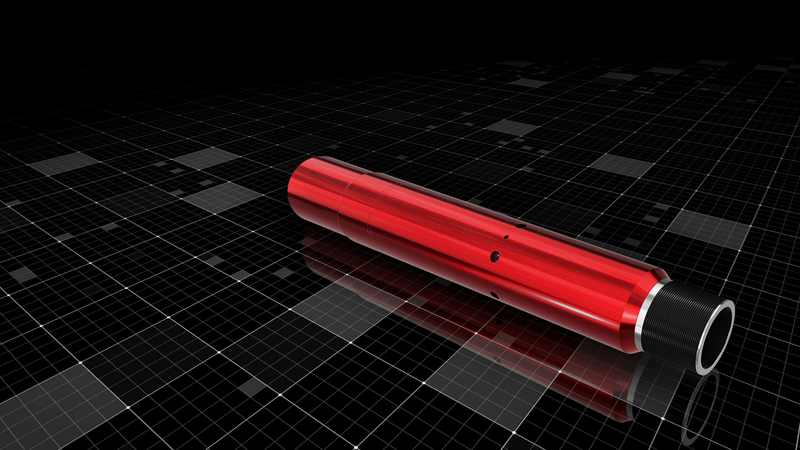

Deep-penetration, high-performance sealant ideal for carbon storage, chemical disposal wells, and permanent plug and abandonment.

ThermaLock™ cement is a non-Portland, low permeability barrier system that is nonreactive with CO₂ and is ideal for ultrahigh-temperature applications.

Provides improved resistance to CO₂, lower permeability, and increased elasticity in comparison to conventional Portland cement systems

Tailored to improve chemical resistance to CO₂ and enhanced mechanical properties that minimize the impact of cyclic loading on the cement barrier integrity.

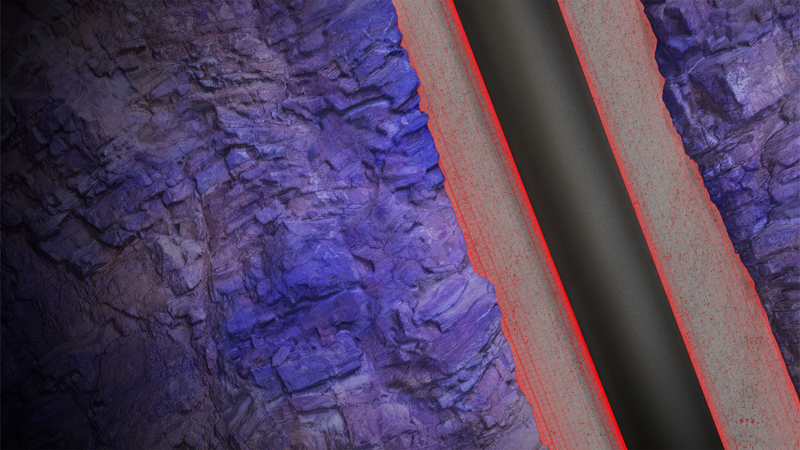

iCem® Service - Superior 3D modeling capabilities allow us to ensure accurate placement of our engineered cement systems and assure their ability to provide long term zonal isolation, even in the harshest CO2 environments.

WellLife® Service – Advanced software modeling capabilities that can ensure the optimum cement system to reduce the risk of damage to the cement sheath, and thereby prevent zonal isolation failure for the life of the well.

Long-term barrier design for carbon capture and storage well construction

35:43

SPE Tech Talk

Proper material selection and best practices are key to design and place annular barriers for long-term storage of CO2.

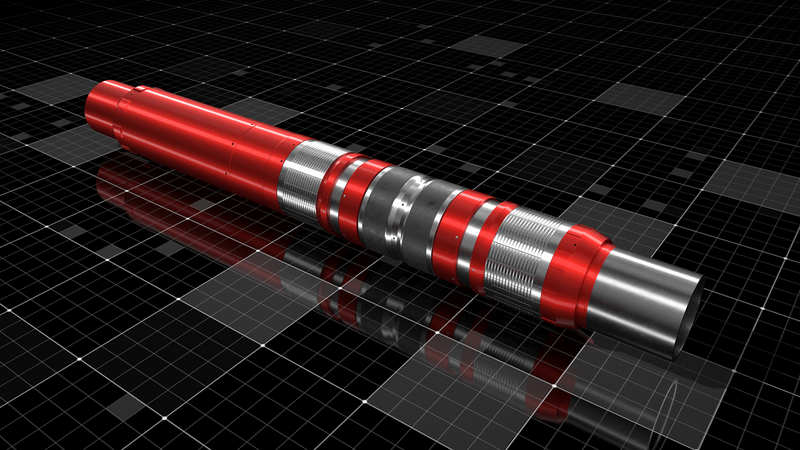

The Fidelis™ stage cementer provides multiple stage cementing capabilities with hydraulic fracturing durability.

The Obex GasLock® casing annulus packer provides a high-pressure, gas-tight, casing-to-casing seal to mitigate annular gas migration.

Cementing barrier design and tailoring digital twin software that enables real-time job monitoring, evaluation, and instantaneous barrier validation.