Search

Search

Search

Search

WellLock® resin system delivers excellent zonal isolation in first CO2 injection well in UAE

Download PDFCCUS

Provide CO2 corrosion-resistant barrier for life of the well

UAE

The capture and injection of CO2 into geological formations in a process known as carbon capture, utilization, and storage (CCUS) is an effective way to reduce global emissions. Cement barriers in these operations face unique challenges attributed to the corrosive environment, harsh injection cycles, and storage requirement length. A sustainable barrier must be ensured throughout a well’s life for proper isolation and to meet injection targets.

As part of a journey to accelerate the decarbonization of operations and supply low-carbon products, ADNOC planned the first CO2 injection well in the UAE. Losses were expected during displacement, which could potentially impact the planned top of cement (TOC). It was essential to design and place a system that could maintain an equivalent circulating density (ECD) below the formation’s fracture gradient to avoid lost circulation and achieve the planned TOC.

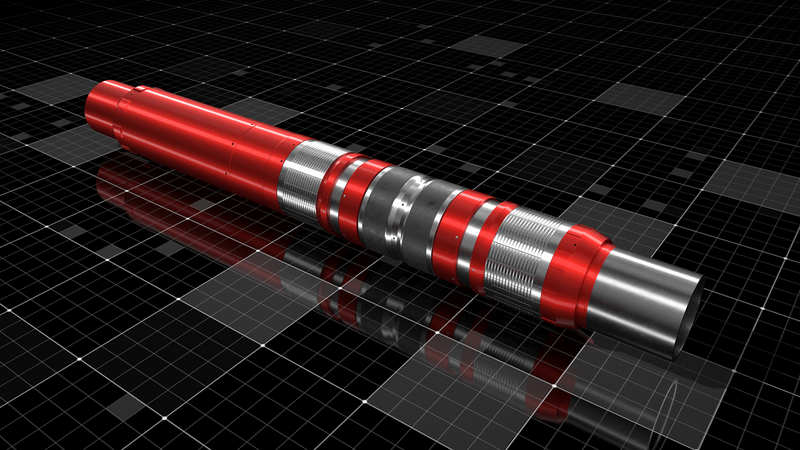

To meet the injection plan, Halliburton proposed a non-Portland system to provide ultimate corrosion resistance and proper isolation over the lifetime of the well. WellLock® resin, a non-Portland system that does not chemically react with CO2 and has ultralow permeability, was deployed to cement 9 5/8-in. and 7-in. casing. WellLock resin also acts as a highly elastic barrier, which helps the system withstand stresses induced by the cyclic loads of the injection operations. Because of the relatively high mud weight, the WellLock resin system was weighted up to 14.5 lbm/gal to cement the 9 5/8-in. casing during the first stage and the full column of 7-in. casing.

CorrosaCem™ cement, a reduced-Portland system, was used during the second stage of the 9 5/8-in. casing cement operation. The CorrosaCem system is designed to minimize components that readily react with CO2. The system’s improved mechanical properties also minimize the impact of cyclic injection.

To mitigate the risk of losses during displacement and achieve cement to surface, Tuned® Defense™ cement spacer, a specialized cement spacer with lost circulation prevention features, was supplemented with BridgeMaker™ II lost circulation material (LCM) and pumped ahead of the WellLock resin. An Obex GasLock® packer, which provides V0-rated secondary mechanical barrier support, was run with an ES II™ HD stage tool to support multiple-stage cement operations, prevent cement system contamination, and help achieve cement to surface.

CCUS well in region

Non-Portland resin system deployed

Confirmed zonal isolation

Halliburton successfully executed a flawless cement operation for the first CO2 injection well in the UAE. No losses were observed during the first stage with 9 5/8-in. casing. The Obex packer and stage tool were successfully operated and set. A cement bond log (CBL) confirmed excellent cement coverage with WellLock resin across all sections of interest in the 9 5/8-in. and 7-in. applications.

Deep-penetration, high-performance sealant ideal for carbon storage, chemical disposal wells, and permanent plug and abandonment.

Tailored to improve chemical resistance to CO₂ and enhanced mechanical properties that minimize the impact of cyclic loading on the cement barrier integrity.

Tuned® Defense™ cement spacer systems prevent lost circulation while optimizing fluid rheology for effective mud displacement.

Improves cement spacer designs to prevent lost circulation.

The Obex GasLock® casing annulus packer provides a high-pressure, gas-tight, casing-to-casing seal to mitigate annular gas migration.