Search

Search

Search

Search

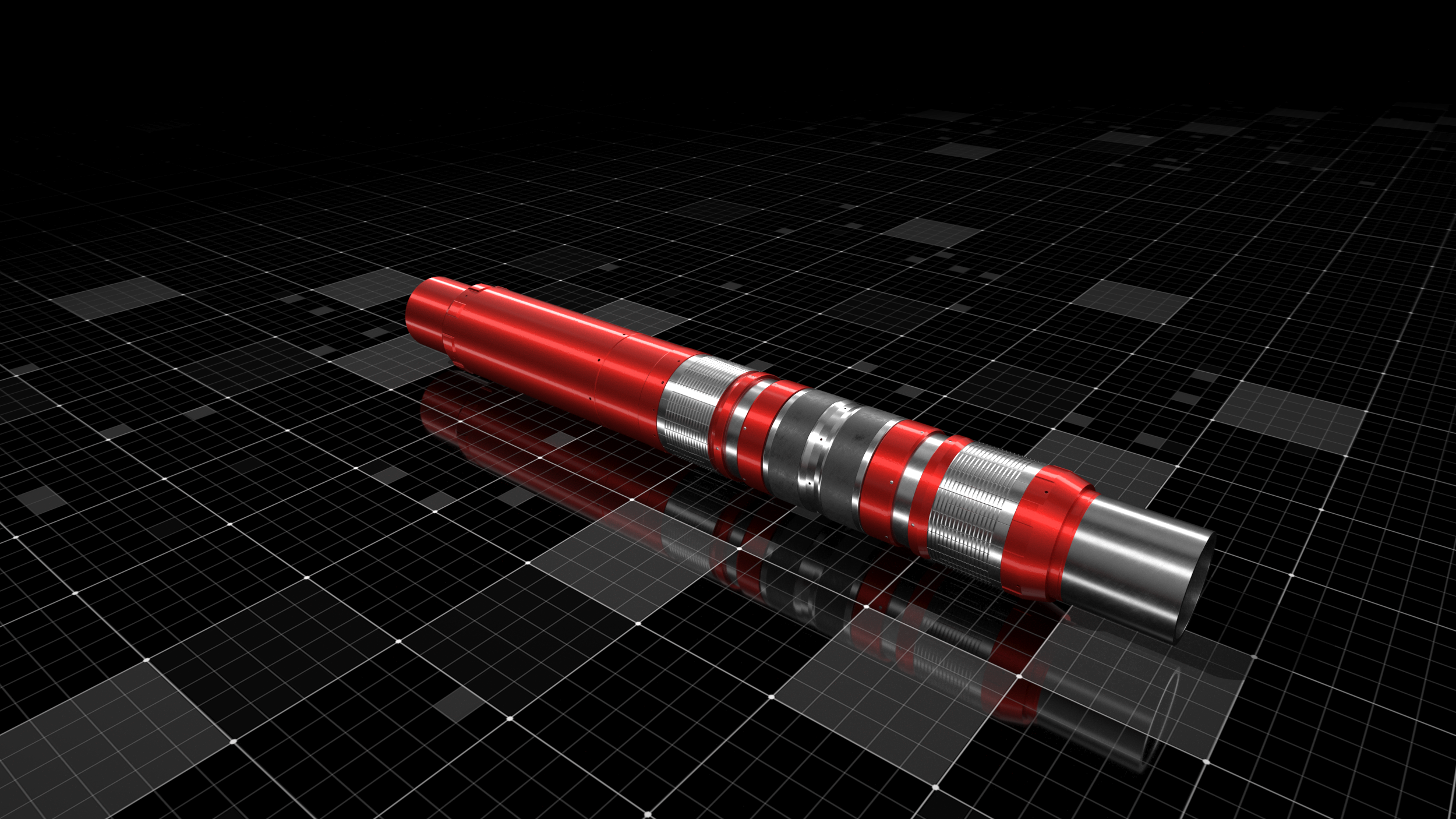

Provides a high-pressure, gas-tight, casing-to-casing seal to mitigate annular gas migration

talk to an expertReliable and effective annular barriers are critical to well management for safety and performance. When sustained casing pressure (SCP) occurs, it is an indication that well integrity has been compromised, often resulting from a failed barrier. SCP impacts wellbore isolation, emissions, well production, and can result in costly remediation.

Achieving proper isolation in high-pressure, high-temperature (HPHT) oil and gas wells continues to be a challenge for many operators. As a result, mechanical barriers are often incorporated into the well construction process to ensure effective zonal isolation is achieved. In addition to preserving wellbore integrity, this sustainable cementing solution helps to reduce emissions and reduce the carbon footprint of oil and gas well construction.

The Obex GasLock® casing annulus packer, which is part of the Halliburton Obex® family of compression-set packers, is a mechanical barrier that provides a high-pressure, gas-tight, casing-to-casing seal. Qualified at the industry’s strongest ISO 14310 V0-rating, the Obex GasLock casing annulus packer provides a superior seal to mitigate annular gas migration and support the hydrostatic weight of annular well fluids above the casing packer in wells with weak formation zones. The Obex GasLock casing annulus packer can be used as a standalone packer or coupled with the V0-rated ES-II™ HD stage cementer for multiple-stage cementing operations.

PSI bidirectional packer holding capability

Fahrenheit packer element rating

Lbf bidirectional barrel slip anchoring capability

Validated to ISO 14310 and ISO 14998 standards