Search

Search

Search

Search

The next generation Tuned Defense cement spacer systems enable dependable barriers, while preventing lost circulation

Talk to an expertThe Tuned Defense cement spacer helps operators prevent lost circulation, meet top of cement (TOC) criteria, and avoid cement fallback to eliminate added costs associated with non-productive time (NPT) and remedial cementing. The new spacer is targeted for applications where operators are dealing with permeable or fractured formations, narrow pore pressure/fracture gradient margins, fields with a history of losses, or areas with strict TOC requirements.

2021 World Oil Finalist Tuned® Defense™ E cement spacer is the next-generation Halliburton spacer. Built on the leading performance of the Tuned Defense cement spacer family, the Tuned Defense E cement spacer is differentiated with the added superior capability to help prevent lost circulation while in environmentally sensitive, offshore applications.

2020 WORLD OIL FINALIST

Safely pumping a spacer system ahead of the cement slurry provides displacement benefits, and when paired with the Tuned® Defense™ cement spacer, enables prevention of fluid losses into the formation.

Tuned® Defense™ and Tuned® Defense™ E cement spacers prevent lost circulation while optimizing fluid rheology for effective mud displacement.

01:14

Successful applications

Success rate

Max temperature performance

Max density performance (lb/gal)

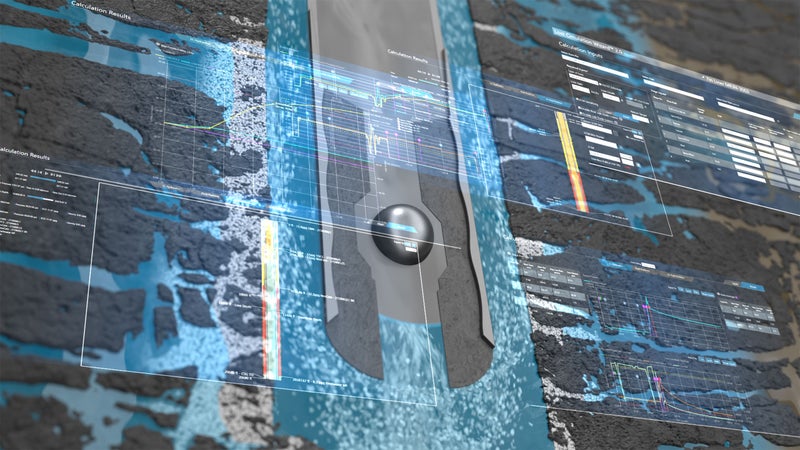

The Tuned Defense cement spacer is an adjustable rheology cement spacer engineered to stop lost circulation during primary cementing before it starts. The tailored spacer system uses a physicochemical mechanism with carefully selected additives to help prevent lost circulation in porous and fractured formations, while enabling downhole fluid separation, cleaning, and compatibility. Rigorous lab testing verifies the new spacer significantly outperforms conventional spacers in cementing jobs where seepage to partial losses are observed. In cases where there is risk of severe losses, Tuned Defense spacer can be enhanced with proprietary lost circulation materials to help prevent severe losses and achieve desired top of cement (TOC).

Because the Tuned Defense spacer is designed to optimize fluid rheology for each well, it helps to improve mud displacement and prepare the wellbore for cement. Pores up to 500 microns are effectively sealed and fractures up to at least 3000 microns are plugged when tailored with proprietary lost circulation material (LCM). Formulations are non-damaging to the formation and support operations up to 325°F, with densities up to 19 lb/gal.

SentinelCem Pro is a unique, single-sack lightweight lost-circulation solution that enables proactive storage at the rig site to cure severe to total losses.

Improves cement spacer designs to prevent lost circulation.

BridgeBlend™ lost circulation material solutions use engineering design algorithms to customize locally available LCMs that address lost-circulation scenarios.

Lost Circulation Wizard™ software allows Halliburton technical professionals to predict the optimal LCM/fluid package to mitigate losses during and after cement operations.

Evaluating LCM selection and concentration for optimal passage, suspendability, and transport.