Search

Search

Search

Search

When you are looking to isolate producing zones in cased or openhole environments, Halliburton Swellpacker zonal isolation systems offer a simple, proven, and reliable solution. The system can swell up to 200%, sealing the annulus around the pipe, achieving effective zonal isolation while retaining seal integrity. Our engineered elastomers are available in three different types:

Count on our Swellpacker systems to provide you with an additional isolation barrier, helping you reduce well construction and completion costs, save rig time, and minimize operational risks.

Deep Water

Operator in Latin America saves $3 million by reducing rig time and decreasing completion time by 10 days.

read CASE STUDYEnhance well integrity with reliable oil-swelling, water-swelling, and hybrid-swelling solutions.

00:21

DATA SHEET

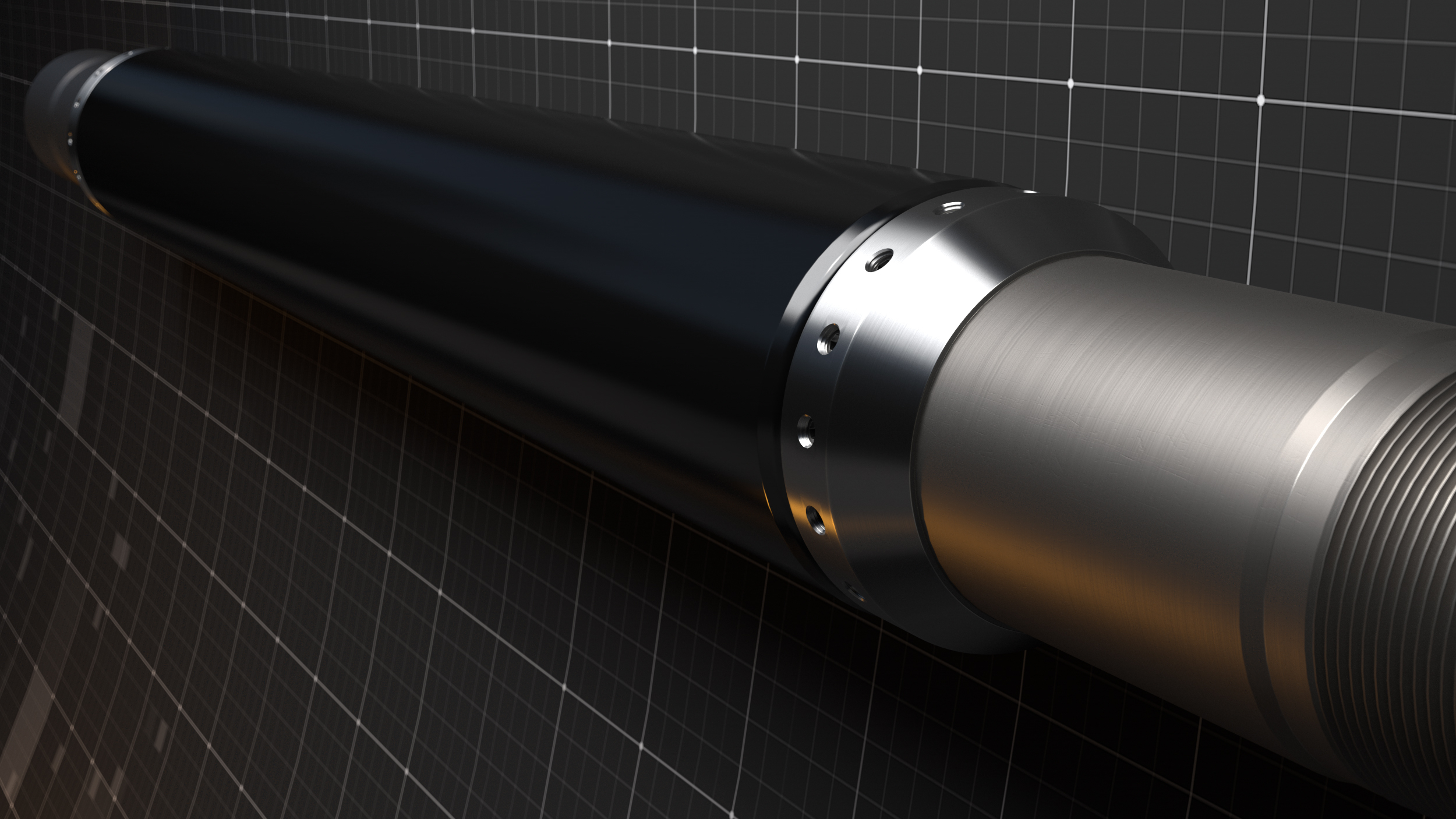

Achieves complete and effective zonal isolation by sealing the annulus around the pipe. Whether oil- or water-swelling, each Swellpacker system is bonded to a base pipe. A cable feed-through version is available, reducing operational risks of failure as well as to allow for faster installation.

Get the specsDATA SHEET

Simplifies logistics, reduces costs, and achieves effective zonal isolation by conveniently sliding onto any non-upset casing or tubing string.

feet, deepest MD run

maximum number of packers run in one well

inches of largest OD built

inches of smallest mandrel

Halliburton Swellpacker zonal isolation systems are based on the swelling properties of rubber in hydrocarbons, water, or both. Once deployed, the rubber retains its flexibility, holding significant differential pressures while running in hole. Additionally, self-healing properties allow Swellpacker systems to adapt to shifts in the formation over time, thus maintaining seal integrity.