Search

Search

Search

Search

Deep Water

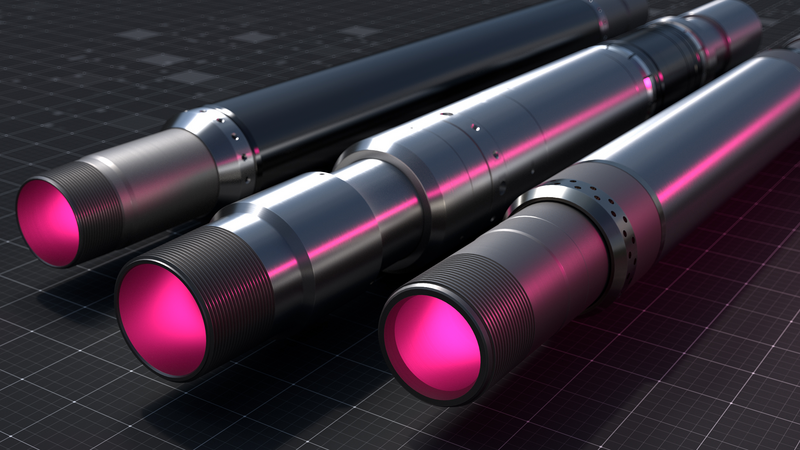

Establish a reliable annular isolation seal in the wellbore with Swellpacker

Offshore, Southeast Asia

A competitor’s osmosis-based swellable packers were not sealing, due to the relatively low temperature and high salinity of the operator’s well

The operator decided to stop using the competitor’s packers and instead chose the Halliburton Swellpacker WS LT system

4 Swellpacker WS LT Slip-on systems were run and set successfully in the lower completion

A major operator in Malaysia was using conventional non-Halliburton swellable packers for zonal isolation in its middle completion. However, due to lack of sealing by the competitor’s packers, the operator was facing several challenges. To rectify the issue, they decided to move away from the competitor’s packer equipment and instead engage Halliburton Swell Technology to help establish a reliable annular isolation seal in the wellbore.

Halliburton Swellpacker water swelling (WS) low temperature (LT) systems were used for zonal isolation, because they allow for full expansion of the expandable sand screen (ESS) before the packer actually sets, avoiding mechanical stresses and movement in the completion system.

Four Swellpacker systems were run and set successfully in the lower completion seal bore. Once installed, permanent downhole gauges (PDGs) confirmed that the Swellpacker systems held around 1,000 psi differential pressure between two different injection zones after seven to eight days.

During the middle phase of a completion, an ESS is typically deployed and a seal with the lower completion is established to prevent cross flow and segregate the injective zone. That, however, was not the case during this operation.

A competitor’s osmosis-based packers were first deployed in the operator’s well, but they were not providing sufficient sealing due to the relatively low temperature and high salinity of the fluid (formation fluid). This was later confirmed by a selective injection test and permanent downhole gauges. The operator knew this was a problem that had to be immediately rectified to avoid even larger issues.

They decided to forgo using the competitor’s zonal isolation packers, and instead engaged the Halliburton Swell Technology team based on its industry-leading experience, technological advantages, and ability to test, build, and quickly deliver equipment.

Halliburton proposed the Swellpacker WS LT system, because its swelling compound is not based on osmosis, thus allowing a hydraulic seal at low temperatures and in high salinity wellbore fluids. In addition, Halliburton offered to test and qualify the low-temperature water-swelling compound at downhole fluid and temperature conditions to prove it would be an effective downhole solution. Testing was done in a span of two weeks in three different customer supplied fluids.

Because the packer design needed to provide sufficient time to run the middle completion and expand the ESS before creating a seal, the team entered the testing data into Halliburton SwellSim® software to help predict packer swell speed. It predicted two days of running time to total depth (TD) with a seal established after four days (including a safety trip for POOH). The test also predicted that the system would hold pressure after six days, in contrast to the five days deemed acceptable by the customer. Test results in two customer fluid systems showed OD expansion as a function of time, proving adequate swell speed at downhole conditions, around 40-60°C and up to 25% salinity.

Based on SwellSim software and test results, Halliburton proposed the slip-on system design to simplify and expedite logistics, as well as add flexibility to the packer space-out.

Swellpacker WS LT Slip systems successfully run and set

to complete testing, manufacturing and delivery

psi for two injection zones for more than 7 days

Halliburton tools were tested, manufactured and delivered onsite within only eight weeks. Four Swellpacker WS LT Slip-on systems were run and set successfully in the lower completion seal bore, and the operator was able to run and expand the ESS during the middle completion with the packer setting after the operation. Additionally, PDGs confirmed that the Swellpacker systems were holding around 1,000 psi differential pressures between two different injection zones seven to eight days following installation.

Halliburton was able to not only provide an effective and reliable solution, but it did so in a short amount of time, saving the operator both time and money.

Swell Technology

The Halliburton Swellpacker isolation system is an innovative technology that offers simple, safe, and reliable downhole isolation.

Download Data Sheet

Expanding, swellable, mechanical zonal isolation systems provide unsurpassed sealing capabilities to help reduce well construction costs.