Search

Search

Search

Search

Halliburton enables greater productivity in development wells, helping to decrease completion time by 10 days

Download PDFDeep Water

Reduce completion times and enable greater productivity from the deepwater well

Offshore Latin America

Operator wanted to reduce completion time and increase reservoir contact

Swellpacker systems in conjunction with VersaFlex® liner hangers were run in the well

Halliburton reduced completion time by 10 days

An operator was trying to complete highly depressurized zones in its deepwater wells offshore Latin America. While this is a challenge in itself, the operator also wanted to reduce completion times and increase contact with the reservoir. Halliburton proposed a joint solution that utilized VersaFlex expandable liner hangers and Swellpacker isolation systems. This design not only saved 10 days of completion time and the associated cost, but also reduced risk and increased production, resulting in additional value for the operator.

During development drilling, a major Latin America operator wished to reduce its well completion times, increase contact with the reservoir to enable greater productivity from the well, and decrease the risk associated with conventional well completions. The wells are producing from a highly depressurized zone, and therefore must be completed using reduced hole sizes.

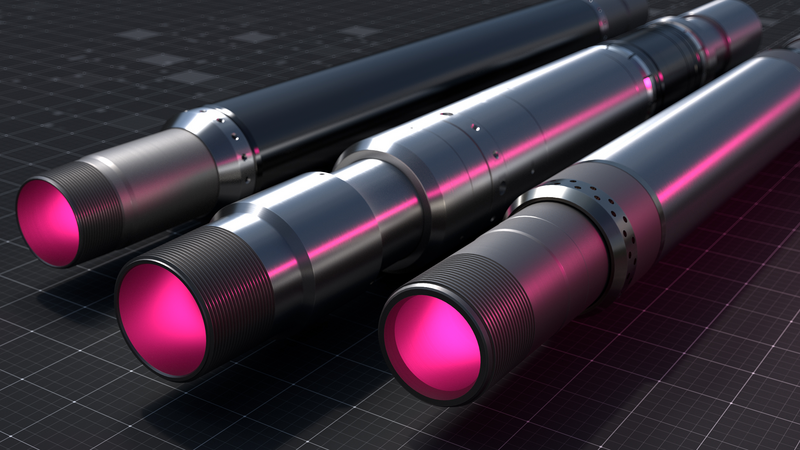

After Halliburton considered the operator’s operational requirements and consulted with its engineering team, it was decided that the operator’s field wells could be more efficiently completed using Swellpacker systems in conjunction with slotted liners. The Halliburton team recommended running VersaFlex liner hangers with 5-inch Swellpacker systems to compartmentalize the slotted liner in different zones, helping eliminate the risk of losing cement to the formation.

Compartmentalization of the producing formation would allow the operator to better manage well productivity should water coning occur, thereby increasing the life-of-the-well. The VersaFlex liner hangers and Swellpacker systems run in the wellbore support life of the well isolation, enabling the above goal to become a reality.

The Swellpacker systems were run into the well for a distance of more than 370 meters (1,214 feet) inside the open hole, during which they performed flawlessly and did not encounter any dragging or restriction issues. Once the Swellpacker systems had fully set, zonal isolation was verified using a SpectraScan® log to ensure the packers had swelled to the open hole. The well was completed ahead of schedule and as expected, without incident or nonproductive time.

NPT

days saved

rig-time savings

The use of Halliburton Swellpacker isolation systems and VersaFlex liner hanger systems helped reduce both the well completion time and the risks associated with conventional well completions. Additionally, the Halliburton solution helped mitigate problems that can often be experienced during cementing operation in depleted formations. Increased production was achieved due to higher contact with the reservoir and effective reservoir management through superior zonal isolation. In this case, a greater area of the producing zone was exposed to production, which also reduced damage to the formation. Also, costs associated with cementing, perforating and cleaning were reduced. Completion time for the wells was decreased from 18 days to eight days which, in turn, resulted in additional savings for the operator.

Swell Technology

The Halliburton Swellpacker isolation system is an innovative technology that offers simple, safe, and reliable downhole isolation.

Download Data Sheet

Expanding, swellable, mechanical zonal isolation systems provide unsurpassed sealing capabilities to help reduce well construction costs.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications