Search

Search

Search

Search

Swellpacker® system seals and sustains 113 tons of force

Download PDFDeep Water

Repair a leak in the operator's hanger tool while anchoring the tieback liner

North Sea

A North Sea operator needed to cut and pull its liner hanger due to a leak discovered in the lower part of the liner hanger tool. The operator then needed to run a tieback assembly to again isolate that section of the wellbore. Halliburton swellable packer technology was chosen to carry out this challenge since it could run through a restriction, expand to isolate the annulus between the tieback casing and the 13 3/8-in. casing, and anchor the tieback in place. The tieback casing was run to total depth (TD) without issue and the Swellpacker® system swelled to seal and anchor. However, due to a faulty casing patch, the Swellpacker system was removed two weeks later. Prior to removing the packer, it was determined that the Halliburton anchoring force simulator proved accurate in predicting the anchor force required for the packer removal.

Due to a leak in the lower part of the liner hanger on the 9 5/8-in. intermediate casing, this major North Sea operator had to cut and pull the hanger. Restrictions inside the upper 13 3/8-in. casing prevented the operator from running a conventional mechanical packer on the 9 5/8-in. x 10 3/4-in. tieback casing string that would be run back to surface. The operator stated that, before the well could be completed and placed on production, a solution was needed in which an isolation packer with a reduced outer diameter (OD) could be run through the upper restrictions in the 13 3/8-in. casing and seal inside the casing. The operator also wanted the packer to hold 250-bar differential pressure and to anchor the tieback string in place for the life of the well.

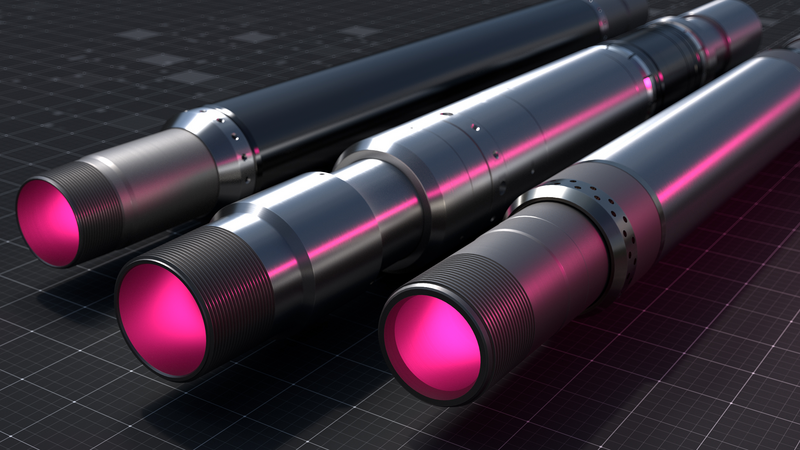

An oil-swelling Swellpacker isolation system was the solution chosen to meet this challenge and to isolate and anchor the annulus between the tieback casing and the 13 3/8-in. casing. Using SwellSim® software, Halliburton engineered a Swellpacker system with an OD of 11 3/4-in. to pass through the upper restriction and comfortably seal inside the 13 3/8-in. casing. To achieve a high differential pressure capability and optimize the anchoring forces, a 29.52 ft (9-meter) element was selected for the Swellpacker system. On bottom, an external casing patch was run to swage a seal against the 9 5/8-in. casing stub.

issues, running the tieback casing

tons actual overpull force

tons predicted anchoring force

The tieback casing was run to TD in the customer’s oil-based mud (OBM) system with no issues. However, two weeks later, a leak was detected in the external casing patch that was used to stab into the 9-5/8. casing. The operator then decided to pull the tieback casing, even though the Swellpacker system had been in the well for 14 days and had begun to seal inside the 13 3/8-in. casing. A series of subsequent operations pulled the Swellpacker system and the related tieback casing section successfully. The faulty casing patch was then able to be corrected.

Prior to removal, the Halliburton anchoring force simulator, a Swell Technology tool developed after years of testing experience, was used to predict the Swellpacker system’s anchoring capability. The maximum actual overpull force experienced during removal of the Swellpacker system was 113 tons as compared to the simulator’s predicted anchoring force of 117 tons, proving the accuracy of the simulator tool.

Swell Technology

The Halliburton Swellpacker isolation system is an innovative technology that offers simple, safe, and reliable downhole isolation.

Download Data Sheet

Expanding, swellable, mechanical zonal isolation systems provide unsurpassed sealing capabilities to help reduce well construction costs.