Search

Search

Search

Search

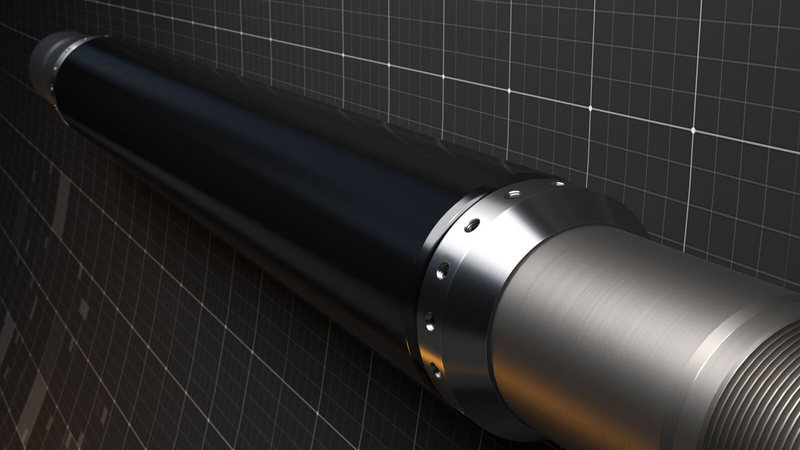

Drop-off system integrated with unconventional high-pressure, long-element, swellable packers to meet well-construction requirements

Download PDFMature Fields

Lower completion deployed with casing scraper

South China Sea

Initial well construction plans in a field in the South China Sea involved deployment of four openhole packers in the 8.5-in. hole section to isolate production zones to a total depth (TD) of 4866 m. These openhole packers were to be deployed on a drop-off liner hanger system with a 4.28-m tieback receptacle (TBR) set at 4230 m to accommodate a tie-back seal assembly in anticipation of potential future fracturing operations. To reduce rig time, a casing scraper sized for the upper completion was also added to the deployment string above the TBR.

Halliburton proposed using a Swellpacker® K2 isolation system (6.7-m element, 9.5-m total length) with a 10,000-psi rating for openhole isolation. A 7× 9 5/8-in. MatchSet® hydraulic drop-off liner hanger system with a 4.28-m upper TBR was proposed for deployment in the BHA using a MatchSet system hydraulic release running tool (HRRT). In addition, a casing scraper was added to the deployment string to scrape the upper casing post the lower completion.

The operator approved the proposed plan, and the BHA reached TD with four swellable packers placed in the open hole. After the release of the MatchSet HRRT service tool, the casing scraper was pulled to the desired depth to scrape the casing near the upper completion packer setting depth of 3892 m. Both the lower and upper completions were successfully deployed and completed.

The operator designated the first well in this field as crucial. During the operation, the installation of multiple long-element swellable packers made the tripping-in process unpredictable. In addition, the inclusion of a casing scraper in the drillpipe string added potential challenges to the HRRT release capability from the MatchSet hydraulic drop-off system.

Halliburton and the operator collaborated on the well construction design, which included the MatchSet system and openhole swell technology. Drilling reports for the 8.5-in. section were sent to the Halliburton technical team onshore to simulate the lower completion process using both WellPlan® torque and drag software and SwellSim® computer software to enhance deployment efficiency. Wellsite instructions (WSI) were established using Halliburton Management Systems for processes and procedures.

String reached with minimal resistance

Service tool string released hydraulically

Days of rig time saved

In recognition of the complex wellbore conditions, Halliburton worked closely with the operator to successfully deploy the lower completion, which saved two days of rig time. The MatchSet drop-off liner system, installed offshore, demonstrated its reliability and efficiency in deploying multiple openhole swellable packers.

The upper completion casing was successfully scraped and cleaned before the full tool string was POOH. Using local service personnel and adhering to proven WSI led to successful installations with a high level of service quality (SQ). No health, safety, or environmental (HSE) issues or nonproductive time (NPT) were recorded.

The quality of the completion tools was verified and the SQ of the site personnel was excellent with no NPT or cost of poor quality (COPQ) incidents recorded.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications

With no moving parts and no inflation required to seal, swellable annular barrier packers remove the inherent risks of mechanical and inflatable tools.