Search

Search

Search

Search

Packers run to 5,700 meters inside the horizontal openhole section without any problems

Download PDFUnconventionals

Run packers to total depth without swelling prematurely in oil-based mud

Norway

A major operator in Norway needed a zonal isolation solution for a long horizontal well with severe dog legs. The operator teamed up with Halliburton to run multiple oversized Swellpacker systems that would expand and seal in the wellbore after being exposed to oil-based mud.

A total of 59 frac sleeves and 12 Swellpacker systems were run in hole to almost 6,000 meters. The Swellpacker systems achieved effective zonal isolation between zones during the high-pressure stimulation work. The operator also confirmed that there were no pressure increases between the frac valves.

The operator was drilling a long 6.5-inch horizontal openhole well from 4,000 meters to 5,700 meters with dog legs up to 8 degrees per 30 meters (98 feet). A zonal isolation solution that could withstand up to 5,000 psi during the acid stimulation treatment was a necessity in order to make this completion a success. Accordingly, conventional cementing methods would be very challenging, so using openhole isolation systems became the preferred zonal isolation methodology. The Swellpacker systems had to be designed with a substantial length and outside diameter to meet the application requirements, and be compliant with the rig operation and production start. The challenge for Halliburton would be to run the packers safely to total depth without swelling prematurely in the oil-based mud. Due to the high-pressure acid stimulation, the systems had to be capable of sealing and holding the required differential pressure both at bottomhole temperatures and under the dynamic conditions created by the treatment while cooling down the environment.

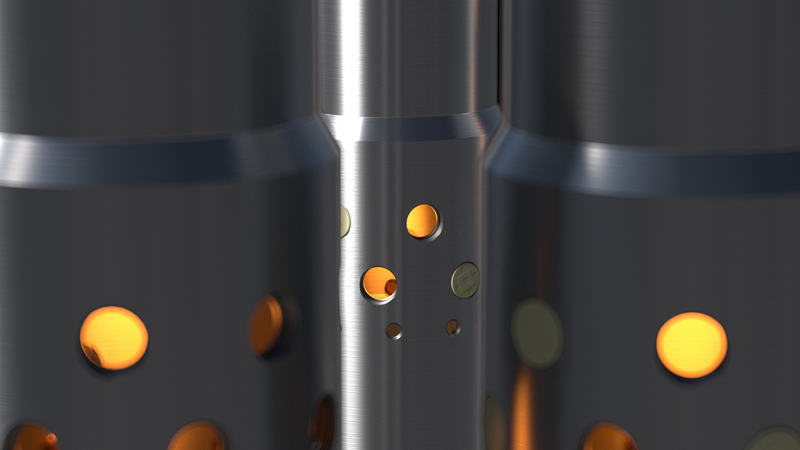

The challenges were carefully evaluated by Halliburton and the customer representative. Following much discussion and design tailoring using the SwellSim simulator software, a Swellpacker system was selected that would meet the requirements of the run-in-hole risk analysis and duration to hold the differential pressure. This completion design using 12 Swellpacker oil-swelling systems would also allow enough time to stimulate the well through each of the 59 frac sleeves.

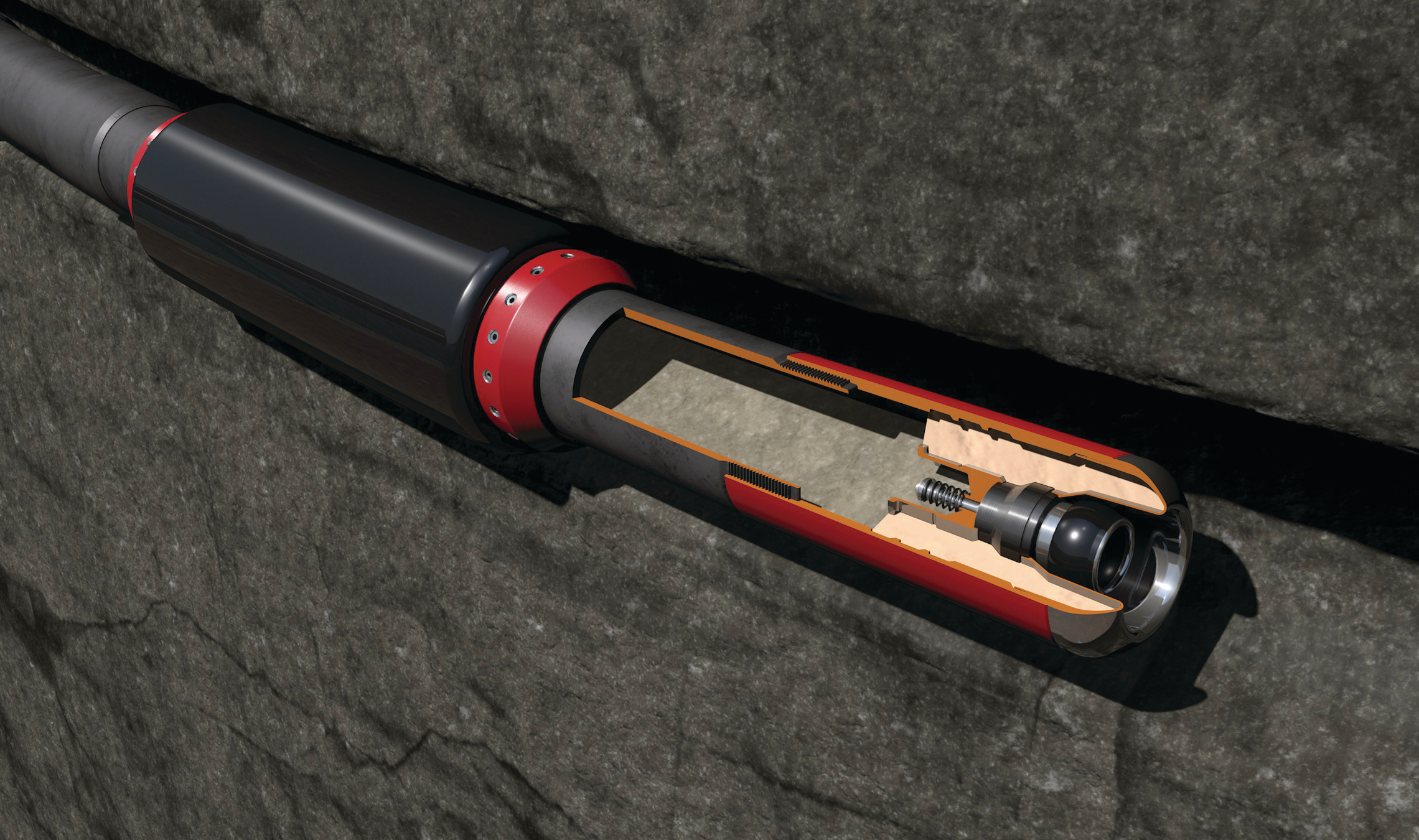

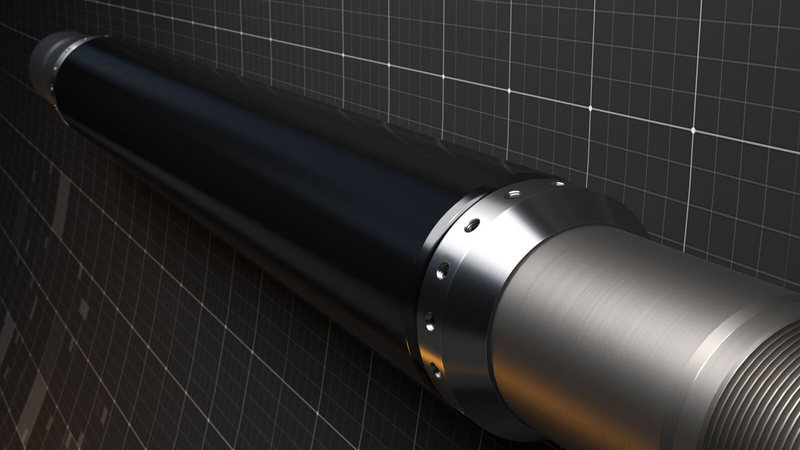

The customized Swellpacker systems had an outside diameter of 5.9 inches and a double-layered delay barrier for the low-temperature range to control swelling time in the XP-07™ synthetic paraffin-base fluid. A 9-meter rubber element was selected to meet the differential pressure requirements and provide long-term effective isolation.

Halliburton’s proprietary SwellSim software enabled effective modeling of the Swellpacker system design, not only under static well conditions, but also under the dynamic conditions of the acid fracturing treatment. This ensured effective performance of the Swellpacker Systems during all phases of the well operations.

Swellpacker systems reached TD

frac sleeves stimulated

loss of isolation during stimulation

The 12 Swellpacker systems were carefully run to total depth, without additional torque and drag, in contrast to another well previously set with a conventional cemented liner. After reaching total depth without losses, the Swellpacker systems achieved zonal isolation during the high-pressure stimulation, and the operator confirmed there were no pressure increases between the frac valves or loss of isolation during stimulation operations.

Swell Technology

The Halliburton Swellpacker isolation system is an innovative technology that offers simple, safe, and reliable downhole isolation.

Download Brochure

With no moving parts and no inflation required to seal, swellable annular barrier packers remove the inherent risks of mechanical and inflatable tools.

Maximize production with multistage fracturing completion systems that help reduce stimulation time and offer selective zonal treatment.