Search

Search

Search

Search

Predict the optimal LCM/fluid package to mitigate losses during and after cement operations

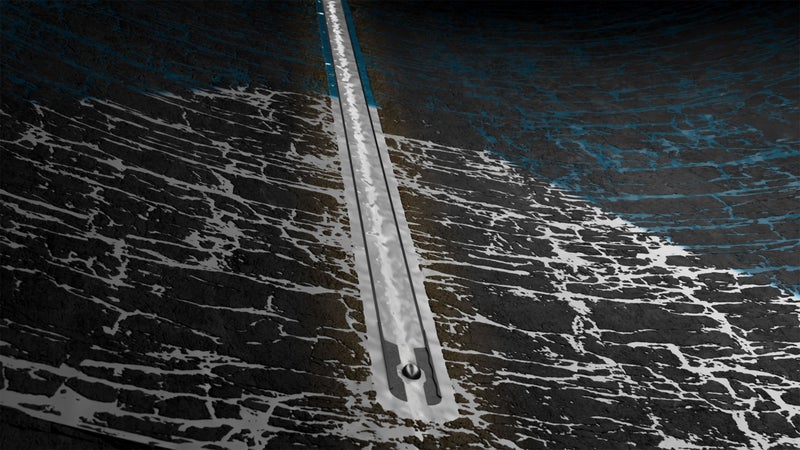

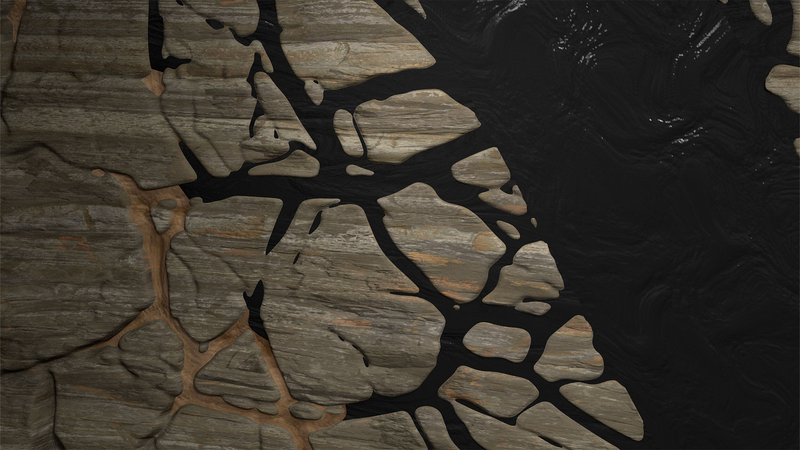

Talk to an expertLost circulation occurs in approximately 20%-25% of drilled wells and costs the industry USD four billion annually. Currently, engineers use their experience and previous well data to design treatments. However, this approach lacks flexibility for different fluid placement strategies. Factors, such as well geometry, downhole fluid properties, lost circulation material (LCM) features, and the characteristics of the loss zone affect wellbore dynamics during these events. Therefore, a more systematic solution is necessary.

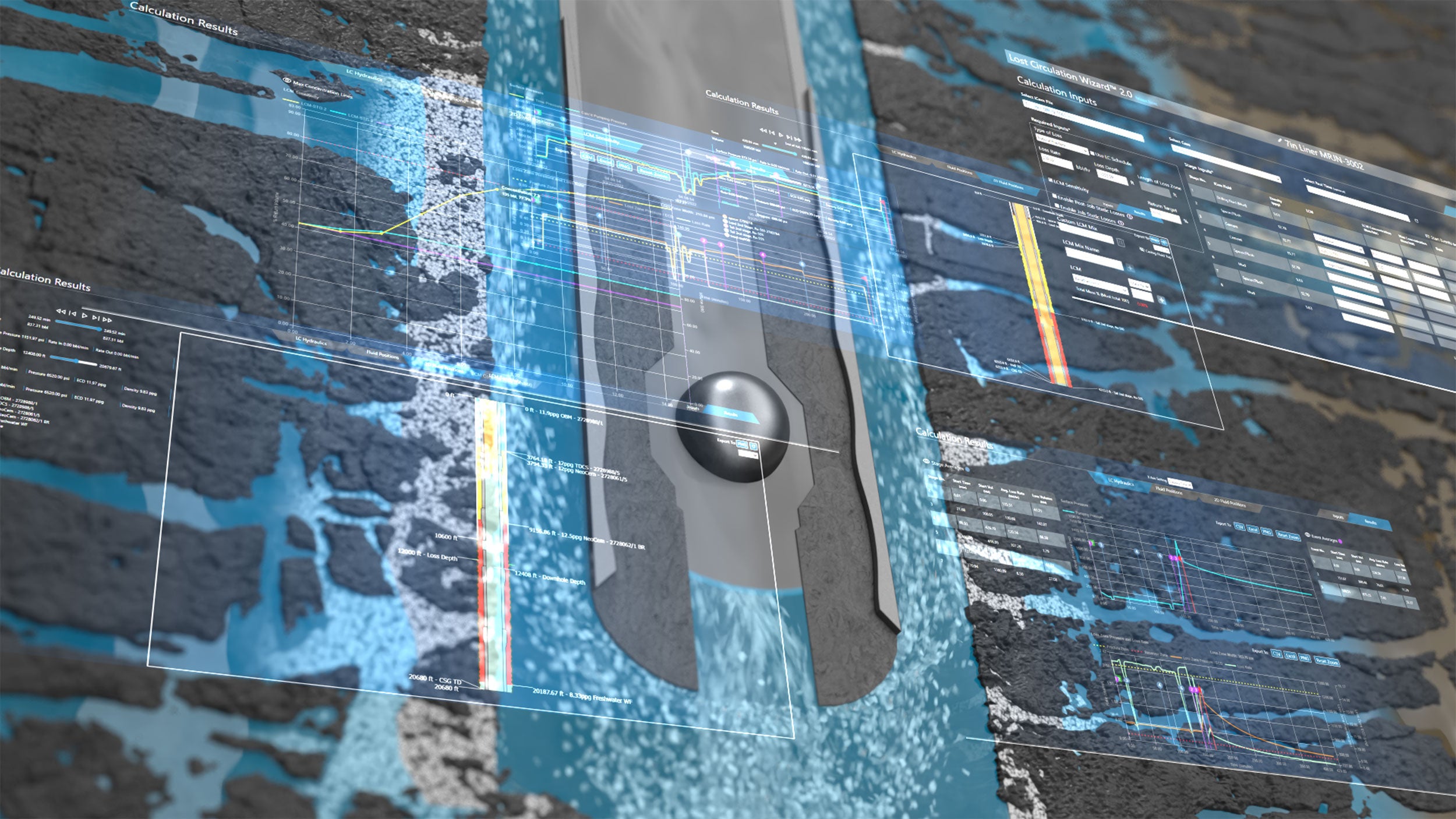

The Lost Circulation Wizard™ software provides an advanced solution by combining wellbore hydraulics with loss zone dynamics. This software can predict the optimal combination of LCMs and fluids for use.

The Lost Circulation Wizard software can tailor various aspects of cement placement that involve LCMs, fluid recipes, and placement conditions to address specific lost-circulation challenges. The software uses a hydraulics engine model that simulates downhole conditions and fluid dynamics to predict slurry behavior under various temperatures and pressures during cement operations.

First, the size of the loss zone is determined through a hydraulic match that compares simulated hydraulic parameters with actual data acquired during the cement operation. After the loss zone size is determined, the model uses that data to predict the loss rate, volume, and pressure during cement operations. The model examines how LCM-laden fluids form a filter cake when lost into a formation and models how the cake builds up to eventually reduce losses to a manageable level. The software’s hydraulics engine model, loss zone characterization, and filter-cake dynamics enable Halliburton engineers to design the optimal fluid density, rheology, pump rates, and LCMs to seal fractures or permeable formations and minimize losses.

The Lost Circulation Wizard software, used alongside the Halliburton Particle Wizard™ software, further optimizes the LCM/fluids package placement in the loss zone. The Particle Wizard software evaluates LCM particle selection and concentration for safe passage, transport efficiency, and static suspendability. Halliburton technical professionals can strike a balance between the most effective LCM/fluids package with one that will clear critical dimensions when both software solutions are employed during the job design and tailoring phases.

Remove uncertainty from the equation when addressing loss challenges. Our approach integrates state-of-the-art digital twins, engineered fluids, and LCMs to create customized solutions.

Halliburton lost circulation solutions minimize well control problems caused by seepage to total lost circulation.

Evaluating LCM selection and concentration for optimal passage, suspendability, and transport.

Improves cement spacer designs to prevent lost circulation.

Tuned® Defense™ cement spacer systems prevent lost circulation while optimizing fluid rheology for effective mud displacement.

SentinelCem Pro is a unique, single-sack lightweight lost-circulation solution that enables proactive storage at the rig site to cure severe to total losses.

BridgeBlend™ lost circulation material solutions use engineering design algorithms to customize locally available LCMs that address lost-circulation scenarios.