Search

Search

Search

Search

Evaluating lost circulation material (LCM) particle selection and concentration for optimal passage, suspendability, and transport

Talk to an expertBy analyzing fluid properties, pump schedules, wellbore geometries, and equipment dimensions, Particle Wizard software can predict an optimal particle solution by calculating the probability of safe passage through critical equipment dimensions, particle suspendability, and transport efficiency. The latest addition to our iCem® service, Particle Wizard can evaluate any particle whether it is from LCM or a mechanical property additive.

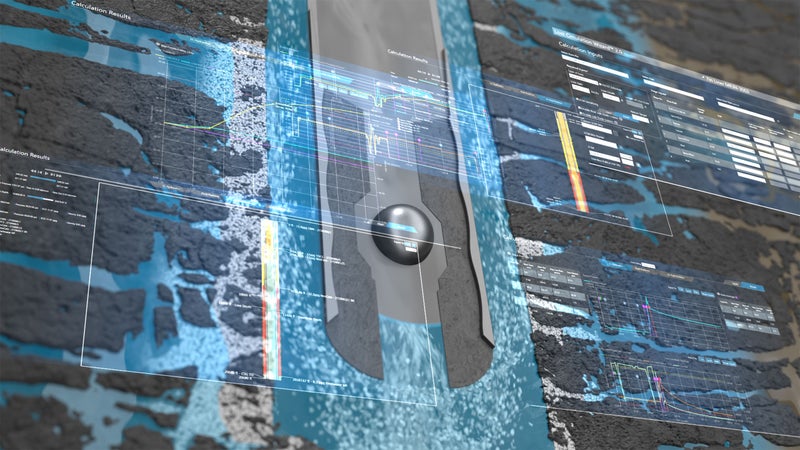

Paricle Wizard software evaluates safe-passage options for particle-laden fluids and helps ensure particle clearance through critical dimensions.

Particle Wizard software promotes particle transport and determines if fluids can effectively transport materials.

Particle Wizard software predicts static suspendability and calcluates the amount of particle accumulation for a given time.

It is important to identify the areas along the wellbore that can restrict the effective passage of particle-laden fluids, such as float equipment, liner hangers, and other downhole tools.

Particle Wizard software can evaluate these critical equipment dimensions to determine the most effective fluid and material concentrations for these restricted area, thus allowing for safe particle passage into the annulus. Looking at defined dimensions of equipment and properties of materials, the software calculates the potential for bridging or packing when passing through restrictions.

Particle Wizard software takes into account fluid and material properties in order to calculate the accumulation per second based on the equipment profile in the wellbore. Typically, this includes the float collar, shoe, and plug set.

By evaluating design parameters for critical areas, along with the circulating rate, Particle Wizard software can determine how much material will accumulate, along with the amount of time left before static suspendability failure.

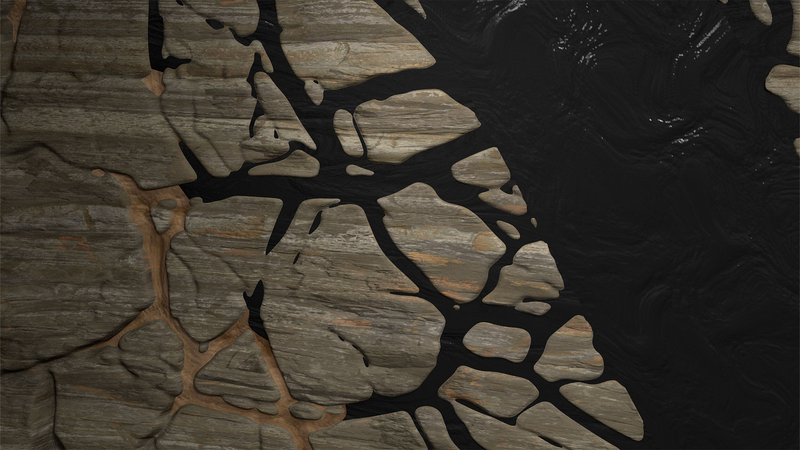

During particle transport, it is important to maintain fluid velocity. The faster these particles move, the less likely they are to settle or salt. However, changes in wellbore geometries can impact velocity, causing particles to settle. In horizontal wells specifically, dynamic saltation begins to bridge around the pipe until operators are unable to continue pumping.

Particle Wizard software compares the fluid, concentration of materials, depths of interest, and pump rates to determine if fluid will effectively carry the material through the annulus or result in saltation.

Remove uncertainty from the equation when addressing loss challenges. Our approach integrates state-of-the-art digital twins, engineered fluids, and LCMs to create customized solutions.

Lost Circulation Wizard™ software allows Halliburton technical professionals to predict the optimal LCM/fluid package to mitigate losses during and after cement operations.

Improves cement spacer designs to prevent lost circulation.

Tuned® Defense™ cement spacer systems prevent lost circulation while optimizing fluid rheology for effective mud displacement.

SentinelCem Pro is a unique, single-sack lightweight lost-circulation solution that enables proactive storage at the rig site to cure severe to total losses.

BridgeBlend™ lost circulation material solutions use engineering design algorithms to customize locally available LCMs that address lost-circulation scenarios.