Search

Search

Search

Search

Remotely achieve full production flow

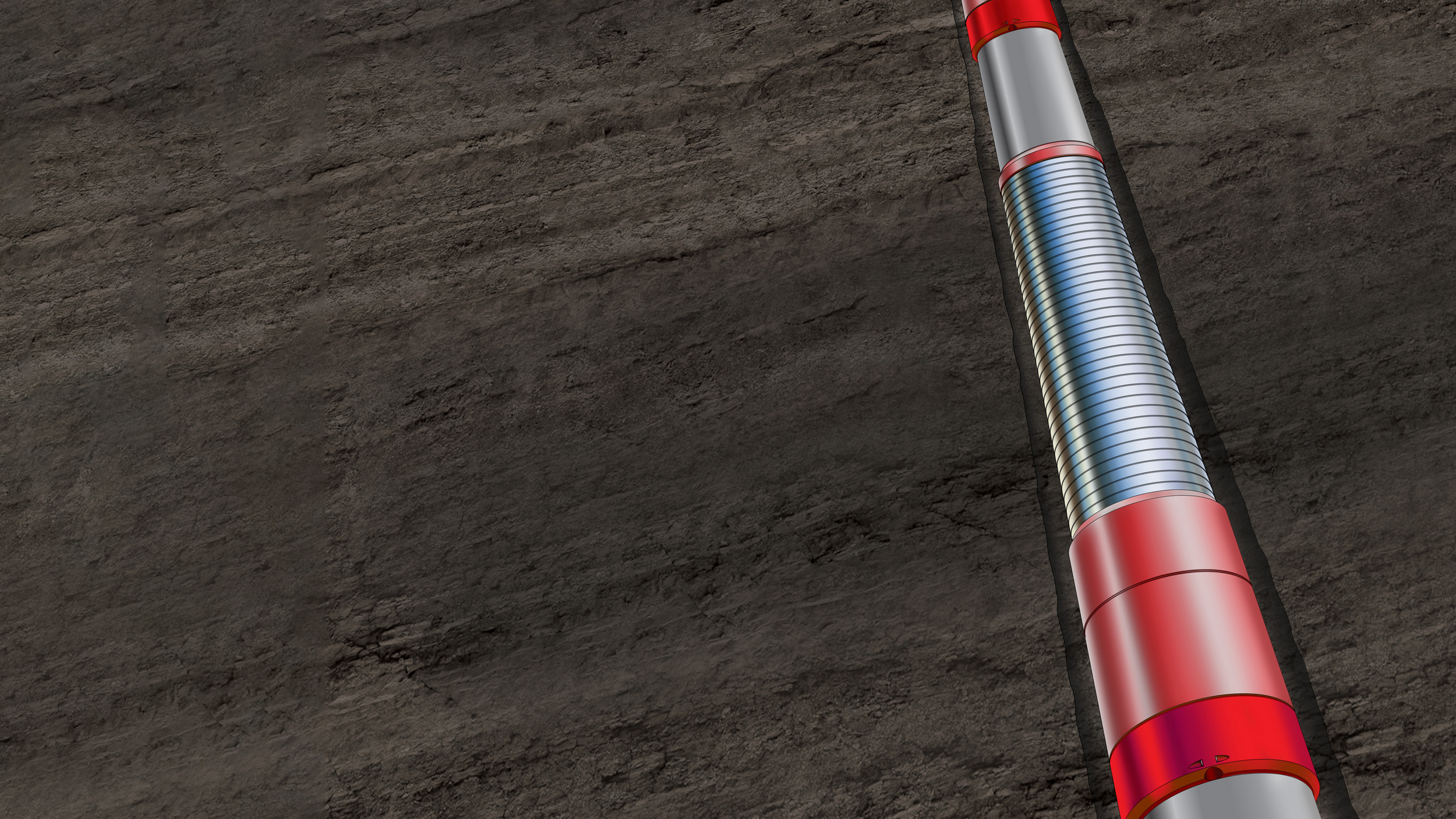

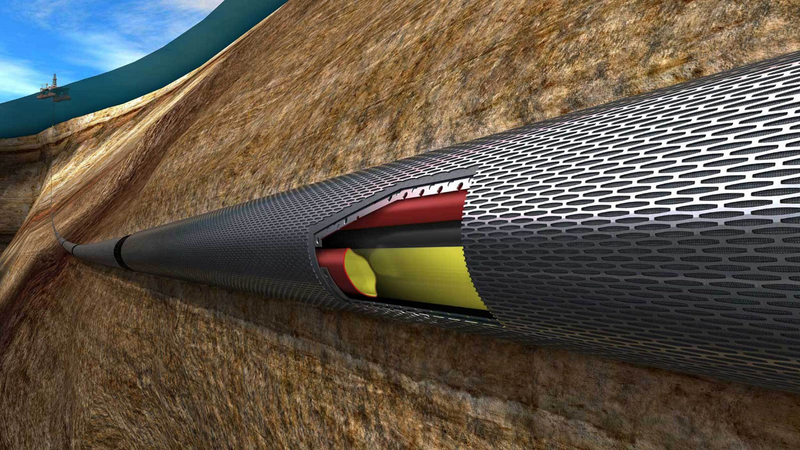

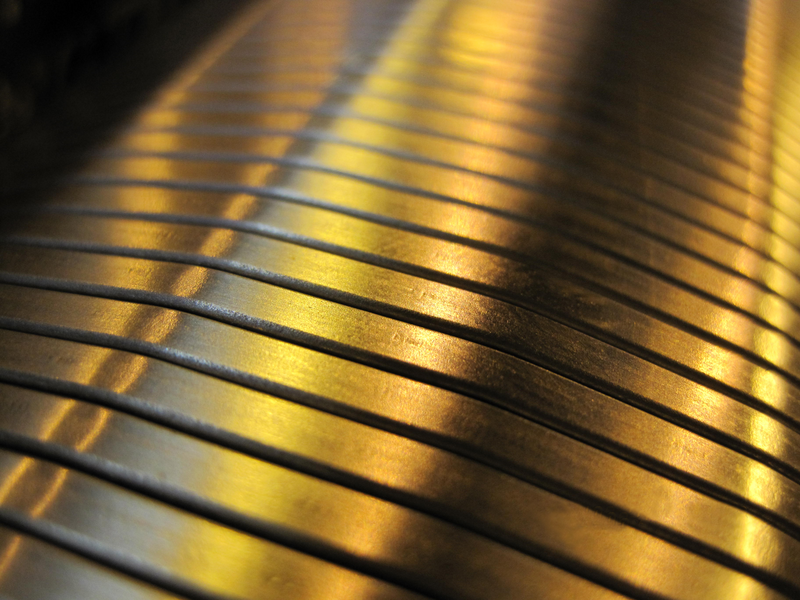

Talk to an expertA remotely opened valve is available for use with PetroGuard® screens and EquiFlow® ICDs (Inflow Control Devices) which holds internal pressure when closed, but opens the screen to full production flow after sufficient internal pressure is applied and released. This remote-open feature enables valuable techniques for pressuring devices in the well during completion operations even when screens are run for sand control. Any model of PetroGuard screen that is compatible with a Halliburton ICD can be built with the remote open feature. Such screens can be supplied with the remote open feature even if no ICD is used.

A remote-open valve is typically installed on each joint of PetroGuard screen, with the valves in the closed position as the screens are run into the well. The valves are sealed to internal pressure only, allowing the screens to fill with well fluid when they are run into the well.

With the valves closed, the entire completion assembly including the screens can be pressured internally to test the tubing while the screens are being run in, and pressure can even be applied to set a packer or operate other tools in the completion string. If a circulation point is left open at the end of the assembly, the well can be circulated from that point without need for washpipe inside the screens; the circulation point would need to be closed in order to apply internal pressure to open the remote open valves and for production of the well.

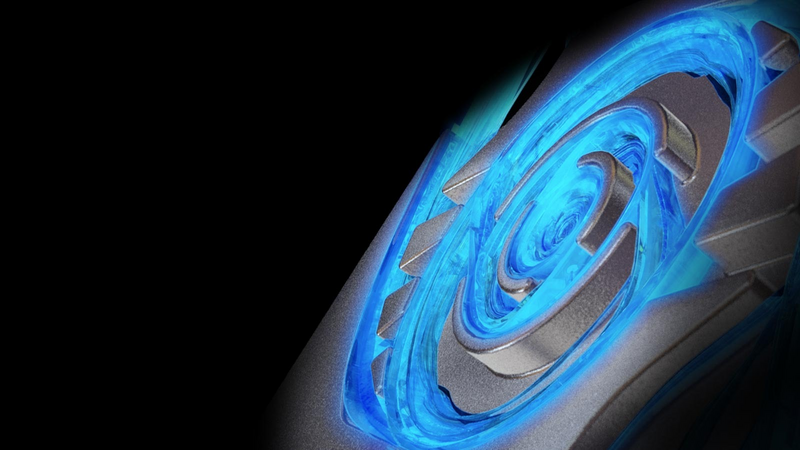

Balances production flow and restricts unwanted production fluid, even with minimal viscosity difference between the produced fluids.

Combines the benefits of inflow balancing with the flexibility to reconfigure the ICD as needed.

How it works

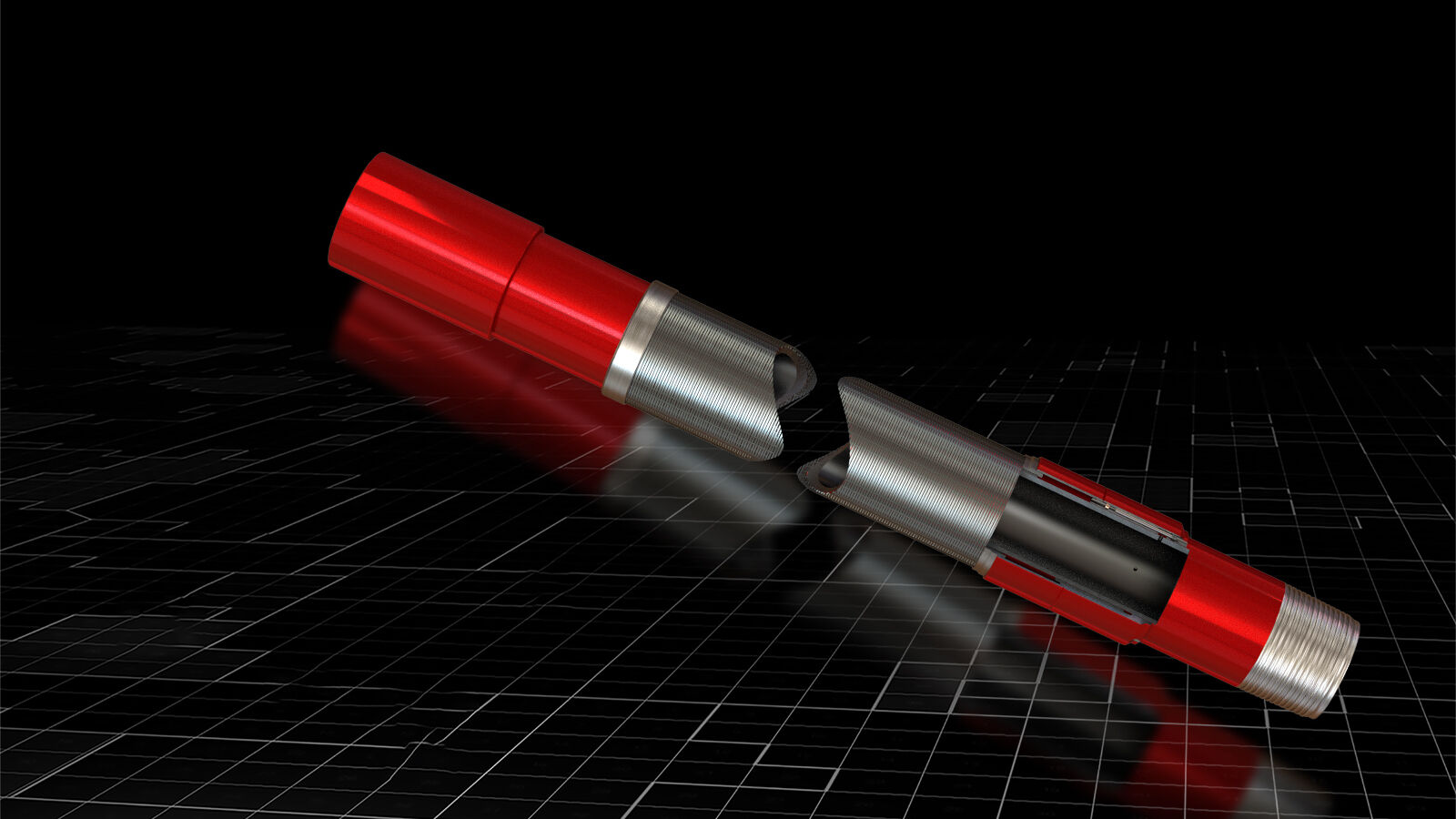

When the screen is pressured high enough internally to shear the valve shear pins, the valves are opened permanently. However, each valve continues holding pressure initially after the shearing action to enable many valves to be opened with a single pressure application. Only when the pressure is released do all the valves actually open for flow.

The valve mechanism is made up of a simple collet and ball assembly, with the collet held in the run-in position by an externally inserted shear pin. During run-in, the screen can fill with fluid through the valve because the valve is not sealed to external pressure, only internal pressure. When enough pressure is applied to shear the pin, the collet shifts and locks in the open position while still holding pressure.

During the application of shearing pressure the ball seals on a solid metal seat that is separate from the collet.

When the shearing pressure is released, the ball unseats and moves permanently to a position inside the collet, where it is trapped and held away from any flow through the now-open valve.

Design and select optimum chemicals, fluid-loss control systems, and completion tools for each well

EquiFlow® inflow control devices help delay and reduce the flow of unwanted fluids, stimulate balanced, and accelerate production.

Whatever the challenge, Halliburton experts stand ready with solutions using the most effective, reliable, value-added sand control screen technology in the business