Search

Search

Search

Search

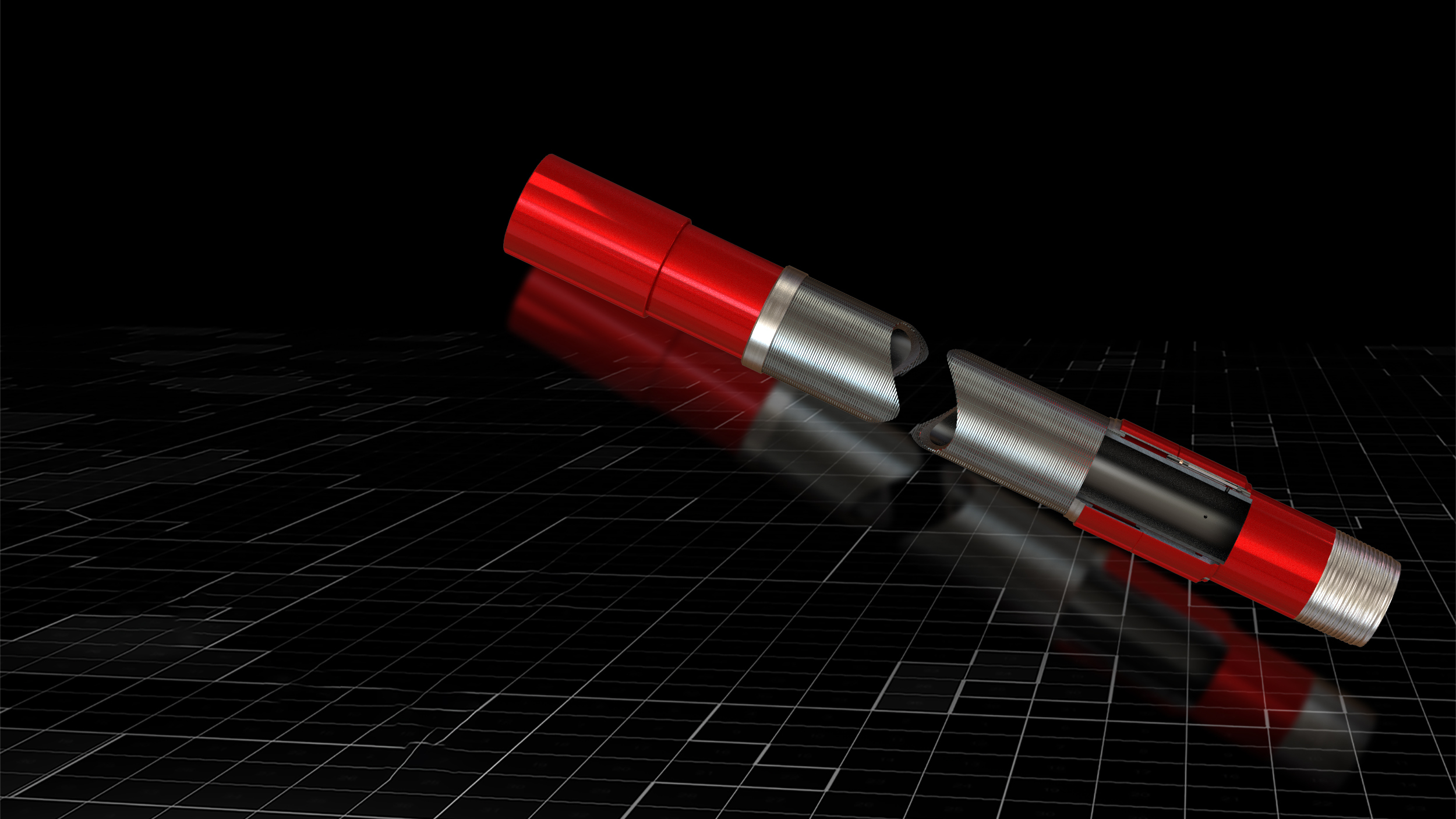

Today’s reservoir challenges call for optimum completion solutions, and since no two reservoirs are alike, having multiple options can be a significant advantage. The Halliburton EquiFlow adjustable nozzle inflow control device (ICD) combines the benefits of inflow balancing with the flexibility to reconfigure the ICD as needed.

Differences in influx from the reservoir can result in premature water or gas breakthrough, leaving valuable reserves in the ground. EquiFlow ICDs are designed to improve completion performance and efficiency by balancing inflow throughout the length of a completion. Placement of ICDs is typically determined during the design phase of a project, but operators often face applications where design flexibility is needed. The EquiFlow adjustable nozzle ICD allows operators to configure the tools closer to the time of installation.

Adjustable nozzle ICDs improve logistics and help reduce delivery time since the tools can be stocked with the confidence that a wide range of configurations is available to meet most well requirements. This allows for determination of the final ICD profile later in the project, such as when the operator receives updated well data during the drilling operations from MWD/LWD. With this reconfiguration capability, backup devices can be used in other applications or projects beyond that which was originally planned.

The EquiFlow adjustable nozzle ICD comes in a range of settings with the flexibility to easily set an indefinite number of times without having to open the tool or use special tools.

Balances production flow and restricts unwanted production fluid, even with minimal viscosity difference between the produced fluids.