Search

Search

Search

Search

Shunt contributed to 100 percent pack efficiency despite challenging openhole conditions

Download PDFMature Fields

Provide a solution system for TOTAL's four-well batch completion

Myanmar

To complete four offshore wells in Myanmar, TOTAL needed to:

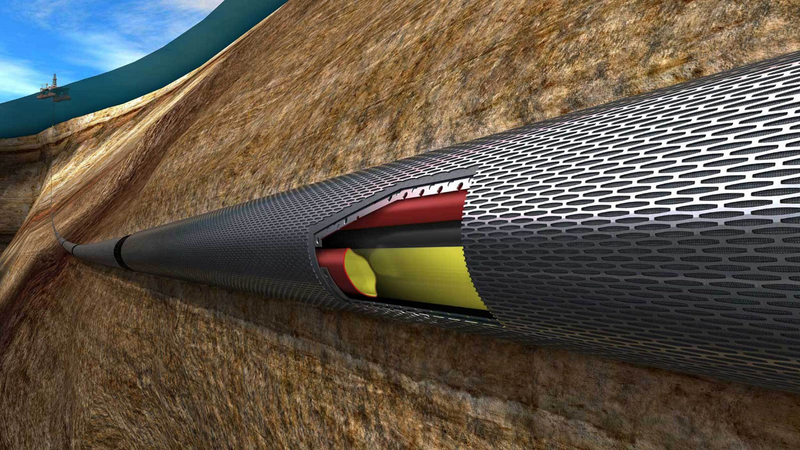

On a project in Myanmar, TOTAL needed a reliable solution to complete its four offshore wells. The company originally considered completing the wells by utilizing an alpha/beta openhole gravel-pack technique that uses completion brine, followed by filter cake breaker placement for mud filter cake cleanup. However, the operator determined that there were risks of hole collapse and potential fluid loss caused by formation fracturing. Given those challenging hole conditions, there was a risk of incomplete packing using the conventional alpha/beta method. The decision was made to adopt the shunt pack technique for this project to help achieve 100 percent pack efficiency for the open hole despite severe hole collapse or full losses.

TOTAL performed several internal studies to determine the most appropriate lower completion solution for its wells. It was identified early on that the four-well campaign required openhole gravel packs to successfully retain and control the formation sands. Additionally, hydraulic simulations were performed and sensitivities were used to assess the potential to successfully execute the sand-control pumping operations. Various scenarios – such as horizontal drain lengths, different gravel-pack fluid weights, completion brine weights, proppant concentrations, and pumping rates – were also analyzed. The conclusion of the sensitivity studies was that, irrespective of the configuration, a significant risk existed in fracturing the formation during the gravel-pack pumping operation. This risk could manifest itself in a premature bridge being formed in the slurry flow path, which could lead to an unsuccessful incomplete gravel pack. Additionally, drilling the well could expose shales that would require isolation.

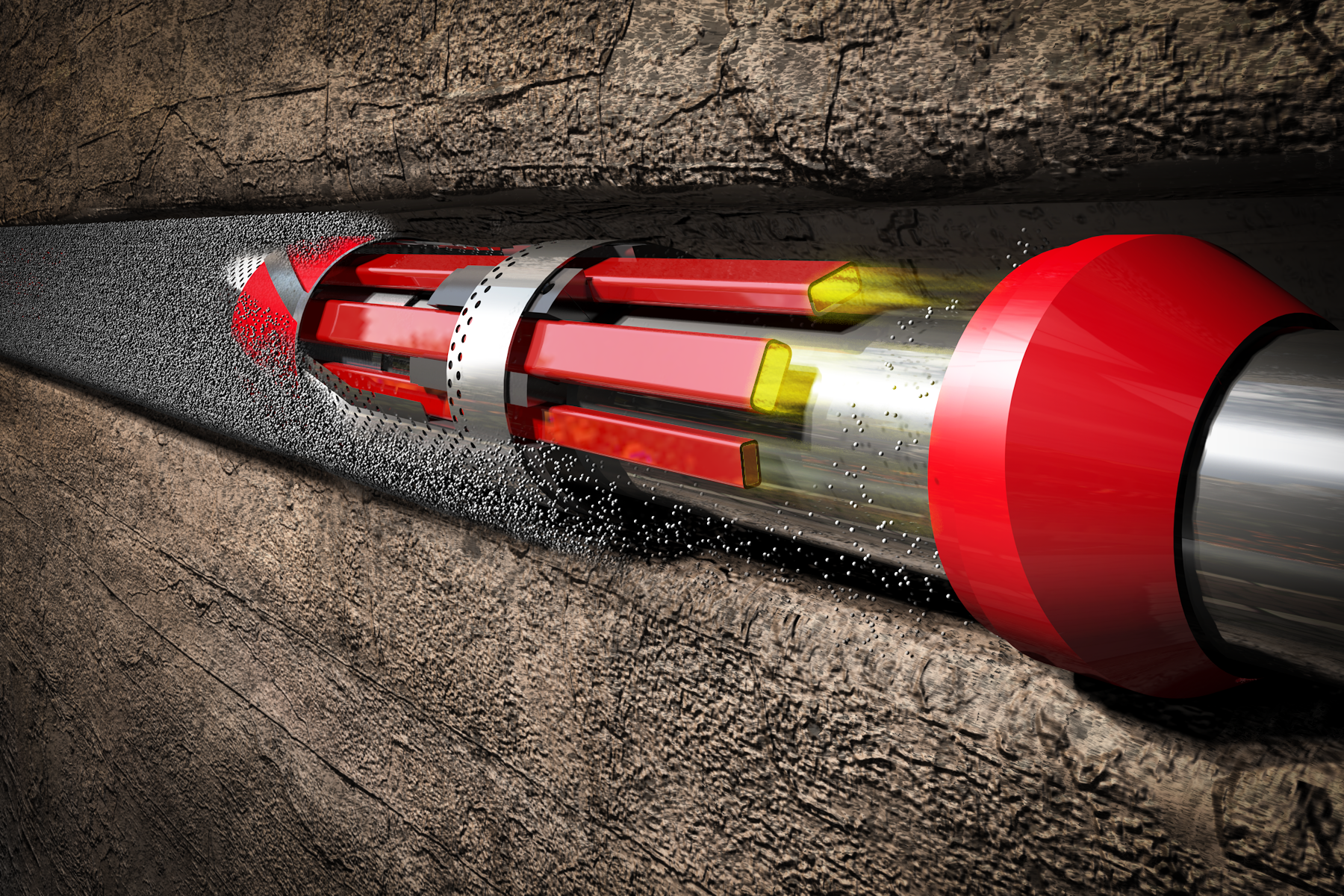

Openhole gravel-pack placement with a shunt screen requires a gravel-pack fluid with excellent, reliable sand-carrying capability despite the fluid environment. It must also allow for transportation in the shunt tube to avoid screenout and to have excellent regain permeability. Thus, Halliburton proposed the PetroGuard® openhole shunt system, using AquaLinearSM service to ensure that gravel-pack proppant could be delivered past any premature bridges and successfully pack the annulus below any bridge, should a bridge exist. The N-FLOW™ 325 filter cake breaker system was included in the solution to be placed across the horizontal open hole on completion of the gravel pack. Two contingency options were made available, utilizing Swellpacker® systems as an openhole isolation barrier: the first option to address a long shale section intersecting the reservoir, and the second option to address a shale zone at the top of the reservoir.

back-to-back successful horizontal completions

pack efficiency for all wells

Four back-to-back horizontal completions were successfully executed due to robust and efficient operational planning and solutions. The shunt activation of the PetroGuard openhole shunt system ensured 100 percent pack efficiency for all the wells, while the N-FLOW 325 filter cake breaker system contributed to the production performance, meeting the operator’s expected targets.

Design and select optimum chemicals, fluid-loss control systems, and completion tools for each well