Search

Search

Search

Search

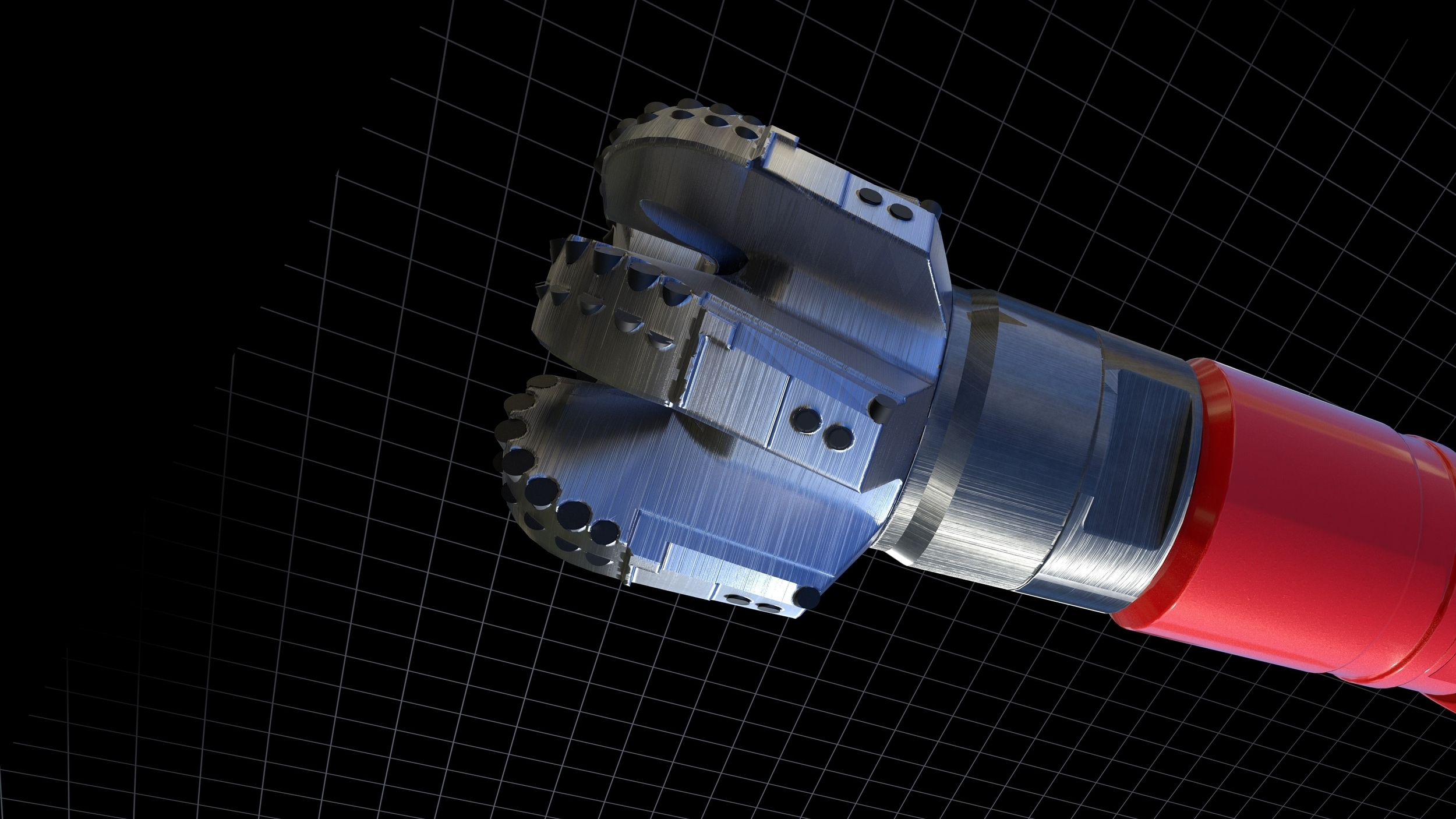

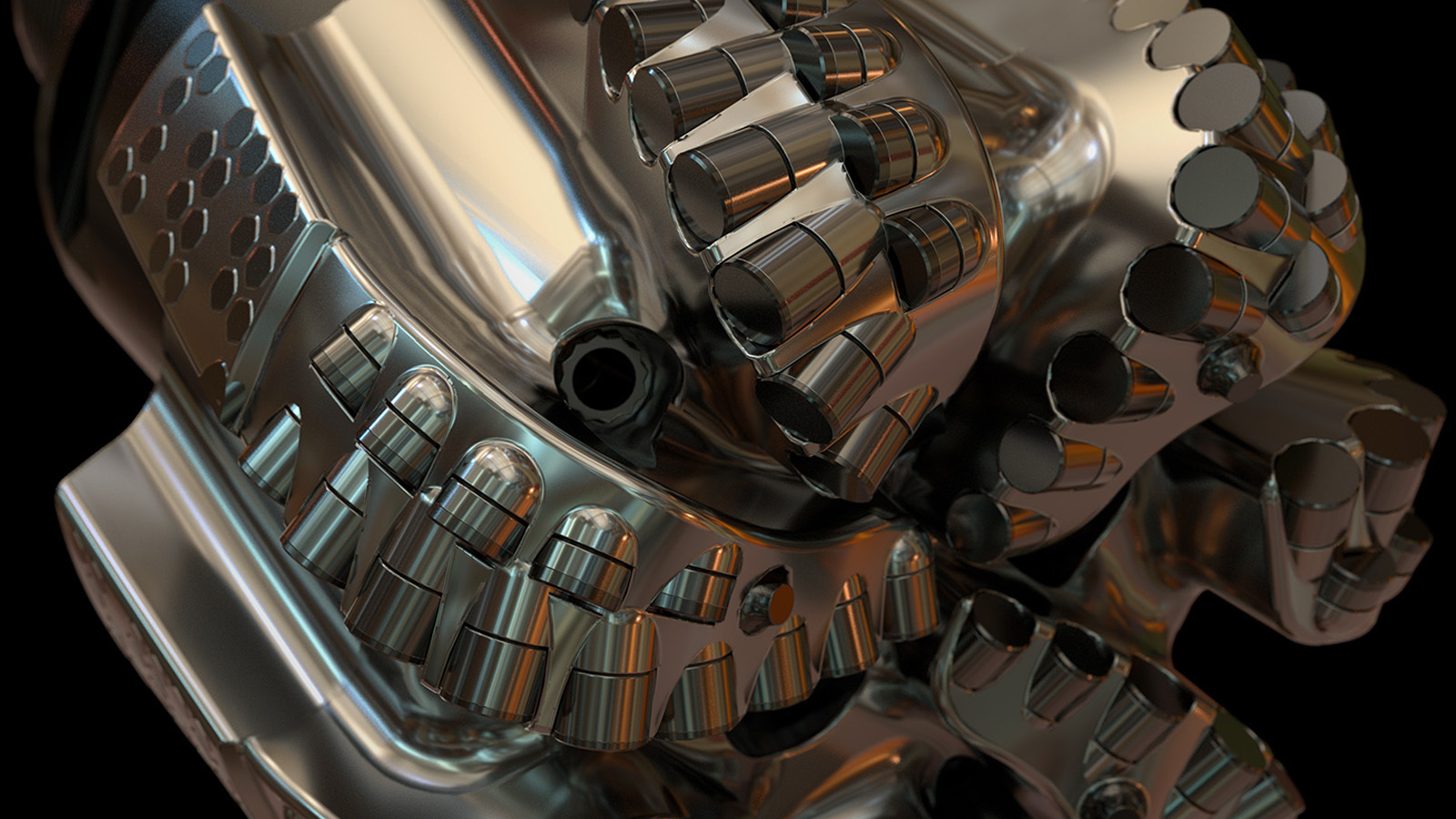

Halliburton’s GeoTech® high energy series of fixed cutter bits blend design theory with practical application-specific knowledge to produce custom-engineered matrix and steel body bits for optimal efficiency and performance—delivering a truly optimized bit design.

Using the Design at the Customer Interface (DatCISM) process, GeoTech drill bits help improve rate of penetration and enable longer drilling intervals—all while lowering cost per foot. Our patented and proprietary IBitS™ design software enables us to create 3D bit designs anywhere by using the latest dynamics modeling, including cutting structure simulation.

Halliburton released GeoTech high energy drill bits which incorporates new features and materials to deliver enhanced performance.

03:40

Case Study / Oman

See how customized GeoTech® fixed cutter drill bits helped one operator improve rate of penetration by 58%.

Read the case studyRock interaction analysis tool helps predict load and motion of a drill bit for multiple scenarios including rock chipping, bent motor, whirl, and more.

Depth-of-cut control optimally positions cutting structure elements to smooth torque fluctuations, while a two-step cutter layout improves performance when primary cutters wear or when drilling parameters change.

Advanced materials include new matrix/binder materials, which increase durability and erosion resistance, enabling innovative steel-blade geometries and aggressive matrix body design.

Improved hydraulics simulation leads to optimum hydraulic design, directing flow with little recirculation, and eliminating stagnant zones to optimize bit cleaning and minimize erosion.

Juggernaut® cutter technology for increased impact and abrasion resistance.