Search

Search

Search

Search

Increased efficiency and required ROP achieved with precise directional control compared to competitors.

Download PDFDeepwater

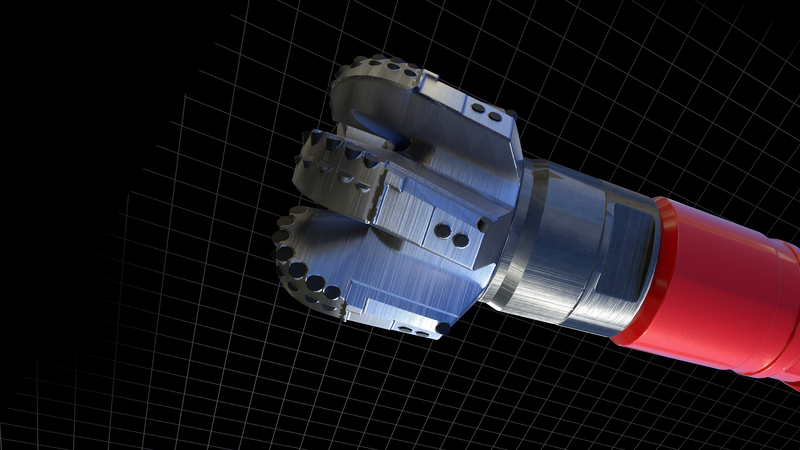

Drill and underream section in one run in challenging deepwater conditions

Caspian Sea

A deepwater operator in the Caspian Sea enlisted Halliburton to drill and underream a 12-1/4 × 13-1/2 in. hole section in one run using a 12-1/4 in. GeoTech GTi65WIMH PDC drill bit, a competitor’s underreamer, and an 8 in. iCruise rotary steerable system (RSS) tool at a depth of 175 meters .

The section consisted of fault planes and layers with unstable “green shale” so directional drilling was restricted in some areas because of the potential for stuck pipe, overpull, and pack offs. Another major challenge was adjusting the drilling parameters to minimize wellbore pressure and keep equivalent circulation density (ECD) as low as possible to achieve balance between wellbore instability and the risk of loss.

Using the 12-1/4 in. GeoTech GTi65WIMH drill bit in combination with iCruise RSS technology, Halliburton developed a strategy to maintain 69° inclination and 268° azimuth to 3,980 meters measured depth (MD), and then build to 71° and turn right from 268.5° to 297° to 4,460 meters MD, keeping the tangent to the end of the section.

Halliburton achieved all directional requirements and the section was drilled smoothly in one run with little to no vibration. Bit performance was good with zero non-productive time (NPT) or issues encountered during drilling. Despite a wellsite cuttings reinjection (CRI) system and wellbore ECD limitations, we maintained an average ROP of 20 m/hr on the longest section ever drilled with iCruise RSS in the Caspian Sea area. The operator was pleased with drill bit performance, and the dull grade meant the bit could be used for further applications at no additional cost.

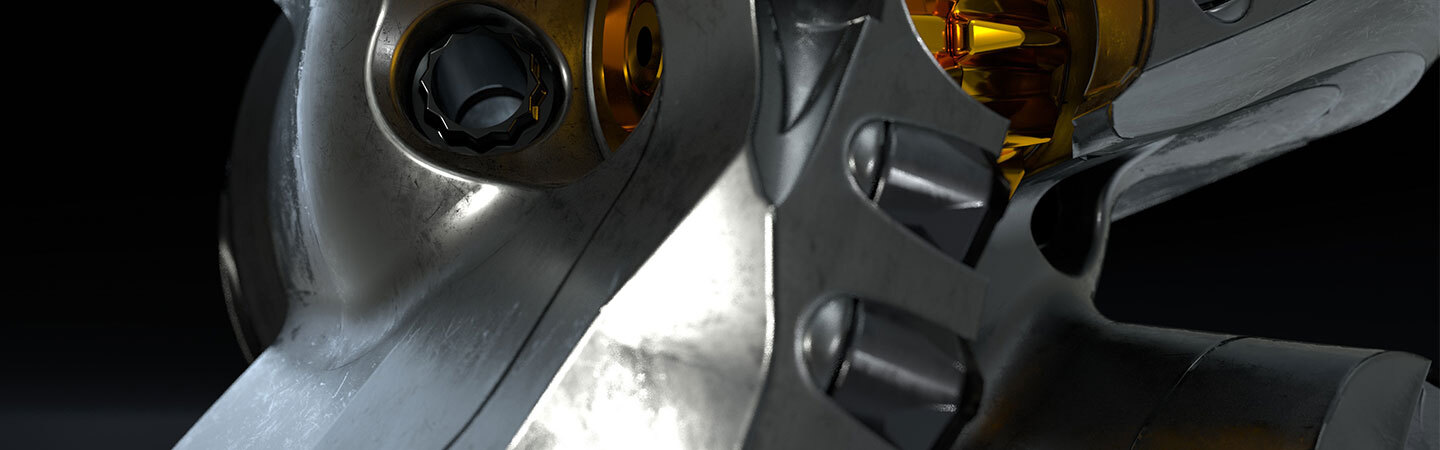

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Juggernaut® cutter technology for increased impact and abrasion resistance.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.