Search

Search

Search

Search

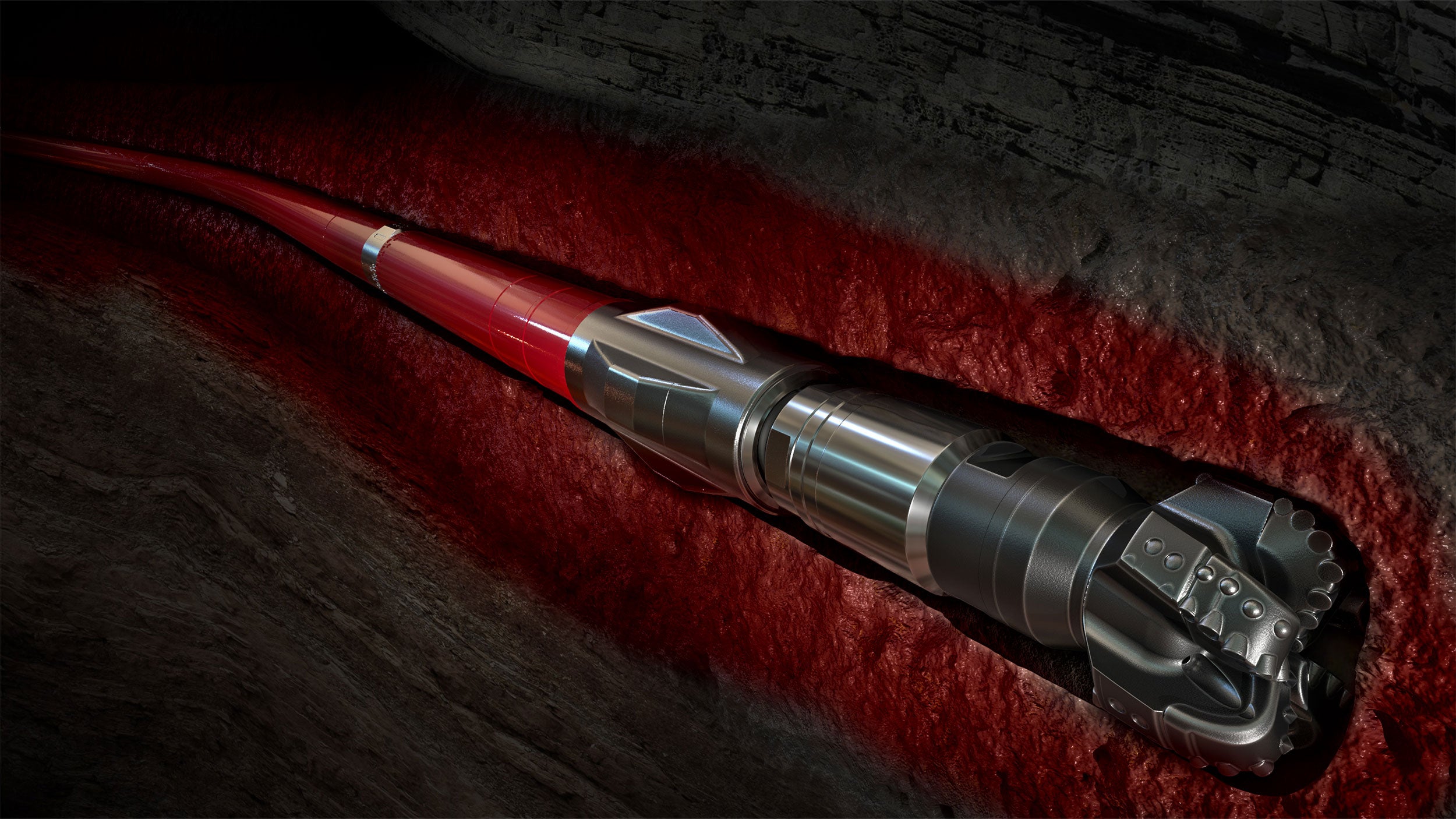

First application of BaraHib® Nano high-performance water-based fluid in Asia-Pacific region reduces filtrate invasion and boosts oil production

Download PDFMature

Stabilize shale and coal formations; reduce fluid and waste management costs

Indonesia

Pertamina Hulu Sanga-Sanga (PHSS) - a major operator in onshore East Kalimantan, Indonesia - has drilled with non-aqueous fluid (NAF) for several years.

In response to environmental regulations and a focus on cost efficiency, the operator wanted to transition to a high-performance water-based fluid (HPWBF) for drilling. After the completion of several wells in the past with HPWBF, PHSS observed lower-than-expected production levels. Their logging results led them to believe that excessive invasion of HPWBF filtrate into the reservoir was the primary cause.

PHSS sought a better HPWBF solution to achieve their goals. The primary requirements were to minimize filtrate invasion in the reservoir sections and achieve the same level of shale inhibition realized with NAF.

PHSS had attempted to replace non-aqueous fluid (NAF) with high-performance water-based fluid (HPWBF) in the past and struggled with operational issues, such as hole instability and pack-off, as well as subsequent logging and production issues. These attempts aimed to reduce the total cost of ownership related to using NAF.

While HPWBF offered improved cost efficiency and acceptable shale stabilization, it failed to provide the same tight filtrate as NAF. This affected logging efficiency and was suspected to be the main reason behind production issues in several wells. This scenario highlighted the need for a new fluid system with minimal fluid invasion that could balance cost, environmental compliance, and performance.

Halliburton conducted a series of laboratory tests to develop a customized solution that would address the challenges in this area. With BaraFLC® Nano-1 nanotechnology wellbore sealant, the technical team formulated and tested several water-based fluid systems to achieve tight filtrate control suitable for drilling sand layers. The tests included a shale study to facilitate microfracture sealing capability, permeability plugging tests (PPT) to help with low fluid invasion, and return permeability tests to examine potential effects on production.

Based on the results, we proposed a customized BaraHib® Nano HPWBF system to the operator for drilling the reservoir section. This fluid system incorporated BaraFLC® Nano-1 sealant along with BaraSure® W-674 shale stabilizer. We used the tracking kit for the BaraSure® shale stabilizer to ensure its concentration remained within specifications at all times. The global technical team initiated the critical first well process with a global technical field advisor on location.

cost reduction compared to planned AFE

reduction in the fluids cost per barrel of oil

BaraHib Nano HPWBF achieved 1 cc PPT spurt in reservoir

The BaraHib® Nano HPWBF fluid system was prepared and maintained within its design parameters. It achieved the target of less than 1cc PPT spurt while drilling the reservoir. The nanoparticle sealant material, along with BaraSure® W-674 shale stabilizer, inhibited and encapsulated the shale while sealing the shale microfractures. This resulted in cuttings integrity, with clear and firm bit marks observed. Logging operations proceeded with no hole fill after logging runs and when running the completion. Wireline logs and all nine planned points for pressure tests and fluid analysis were performed. The pressure points were acquired in less than 20 minutes per point and indicated no sticking issues or excess fluids during logging. Fluid samples taken showed no contamination from drilling fluid filtrate, confirming that all samples were formation fluid.

Compared to the offset wells with similar architecture and drilled with NAF, this well demonstrated a significant cost reduction in fluid costs with the BaraHib® Nano HPWBF system. Additional savings were achieved by eliminating the waste handling associated with NAF.

There was a greater than 10% cost reduction compared to the planned AFE. In addition, the product system helped the operator reduce the cost per barrel by 30%. Oil production has exceeded the client’s expectations.

Expansive portfolio of engineered high-performance water-based fluids and additives that can be customized to meet your specific challenges

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.