Search

Search

Search

Search

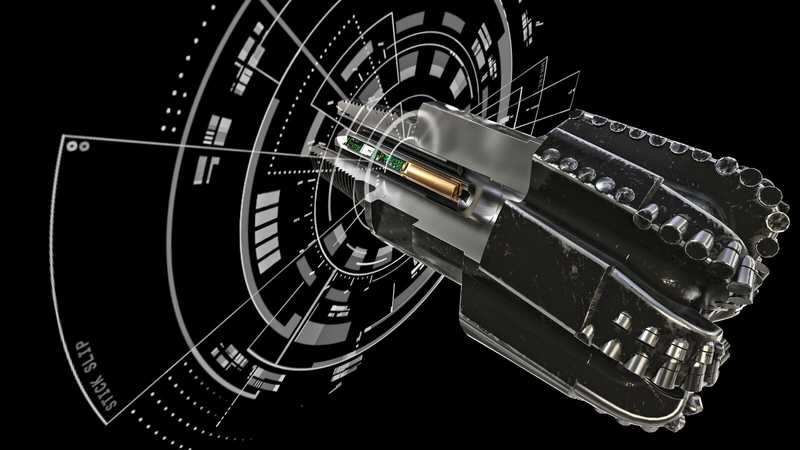

Cerebro® in-bit sensor drives Cruzer™ depth-of-cut rolling element and Shyfter™ cutters to deliver outstanding curve performance.

Download PDFUnconventionals

Provide efficient drilling of an unconventional well in the Rockies

North Dakota

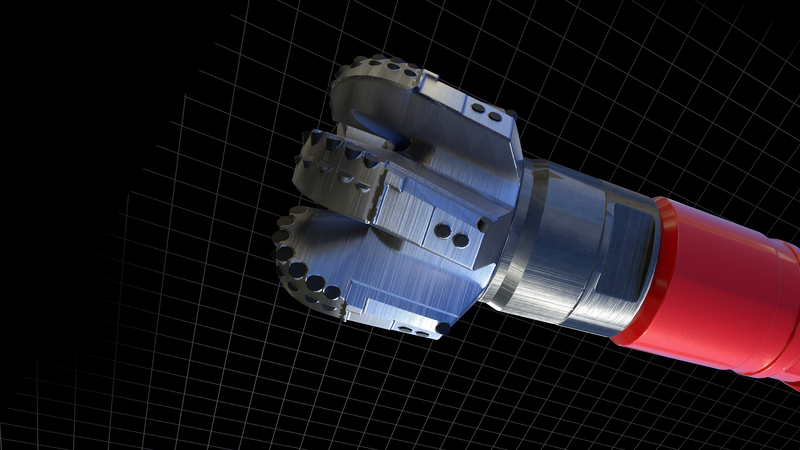

Historically, drill bit design primarily relied on data capture at the surface. The introduction of Cerebro® intelligent bit technology gives Halliburton Drill Bits and Services the ability to map the downhole motion of the bit and any associated drilling dysfunctions. We can now use this data to gain a better understanding of the given application and design a more efficient bit for the drilling conditions. Using the 8-3/4 in. GeoTech® GTD55RMU Cerebro-enabled drill bit design, an operator in the Williston Basin achieved optimal engagement of the Cruzer™ depth-of-cut rolling element through the curve, without sacrificing efficiency. The Shyfter™ R2 cutters provided required durability while improving lateral efficiency to achieve the required build rates for the interval.

Initial Cerebro tests were conducted, collecting data directly from the tool, which showed that when the Cruzer rolling elements were engaging, the fastest rate of penetration (ROP) was reached, while also minimizing torque. However, the Cruzer’s rolling elements were only engaging small percentages of the run. The GeoTech GTD55RMU Cerebro-enabled drill bit design incorporated these findings by changing the engagement of the Cruzer cutter. After decreasing the depth of cut at which the Cruzer cutter was engaging, results continued in a positive direction, thus, optimizing drilling performance.

The Cerebro intelligent bit technology provides the following advantages in tough drilling environments:

Analyze and understand drill bit performance quicker and more efficiently with the Cerebro™ in-bit sensor.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.

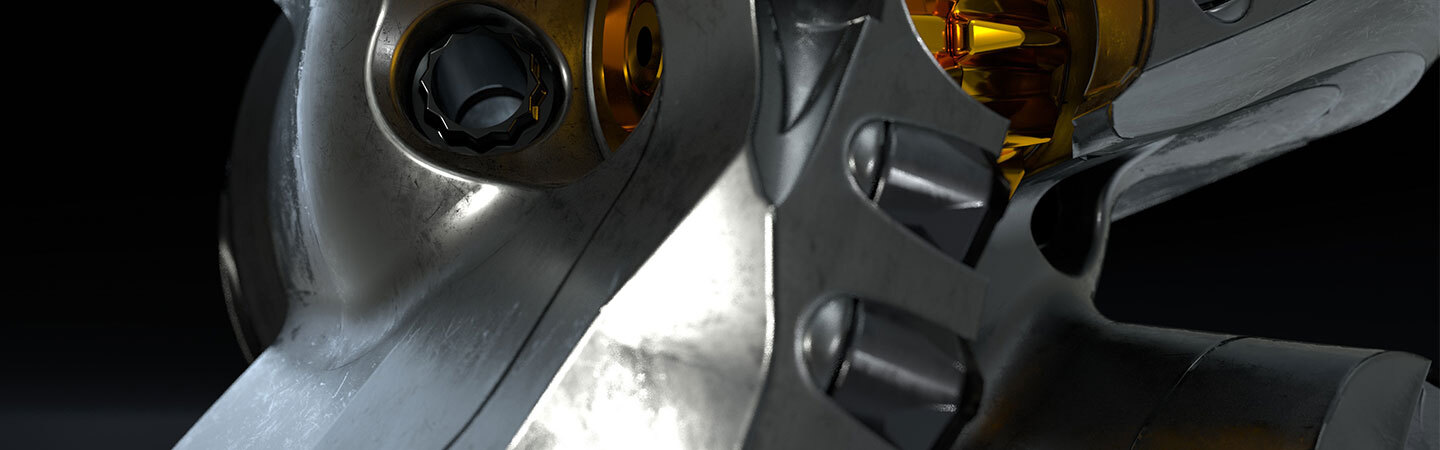

The Cruzer™ depth-of-cut rolling element increases tool face control for improved drilling efficiency and directional control.