Search

Search

Search

Search

Customer-centric approach: empowering local solutions for unmatched industry efficiency and continuous improvement

talk to an expertWith various drilling applications around the world, there is no one-size-fits-all solution. Our unique Design at the Customer Interface (DatCI™) process involves highly trained Application Design Evaluation (ADE™) specialists located around the globe. These specialists collaborate directly with customers to provide application-specific solutions.

These specialists integrate local knowledge with some of the industry’s most powerful software, collaborating with customers to provide a tailored solution to their drilling, reaming, and coring needs. Furthermore, the manufacturing team is organized to deliver best-in-class cycle times allowing our customers to realize performance benefits quickly.

middle east

Performance record set by drilling 2,336 ft with a motor BHA, achieves an ROP of 267 ft/hr

read case studyWe execute our DatCI process in collaboration with operators to understand their challenges and design customized solutions to optimize their operations. The DatCI process comprises five steps below—each designed to enhance efficiency and effectiveness.

We collaborate with operators to discuss future targets and challenges. Our goal is to optimize efficiency and performance in subsequent cycles.

We work directly with operators to understand their operation, from offset performance to mineralogy, rigs, and drilling tools that all play a role in drilling performance. Determining key performance indicators (KPIs) to understand operator expectations is equally important

Our local experts design tailored solutions using advanced simulation software. They use their knowledge to maximize drilling efficiency and performance.

We establish drilling parameters, expedite custom manufacturing, and deliver solutions to rig sites. Monitoring performance and collecting data are crucial during this phase.

We compare predicted performance with actual results, prepare case histories, perform field analytics, and capture lessons learned for continuous improvement.

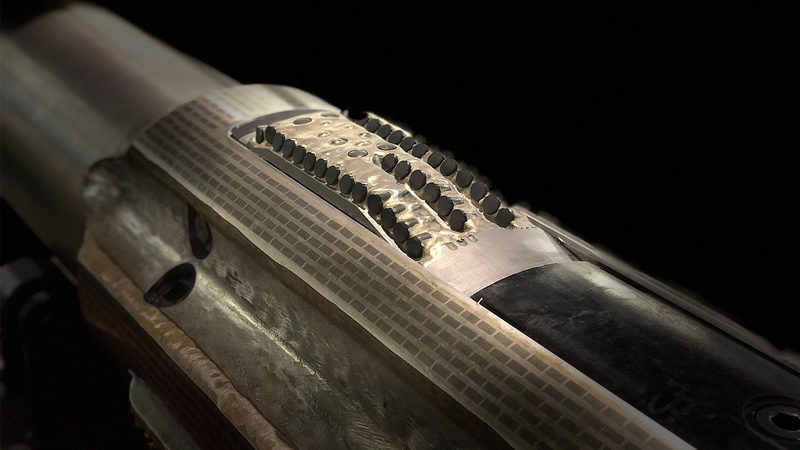

Halliburton delivers high-efficiency fixed cutter drill bit solutions that are customized for every application.

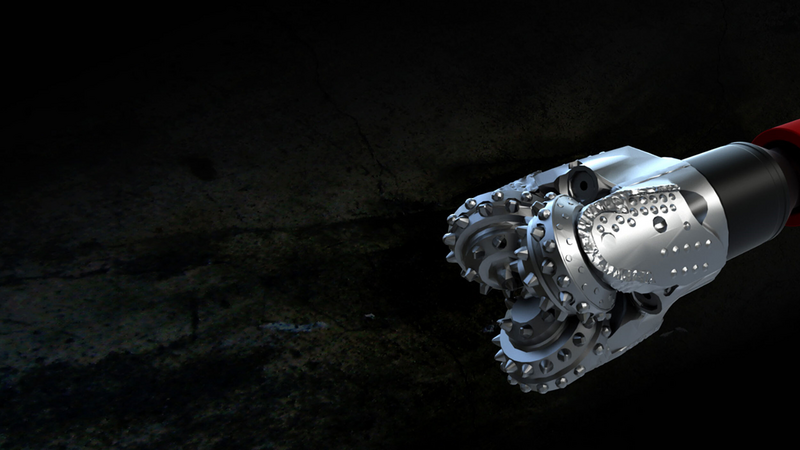

Halliburton roller cone drill bits are designed to meet your specific application needs.

Coring systems that maximize recovery of high-quality core samples in the most extreme environments.

On-demand activation/deactivation systems where tool reliability, durability, and hole quality of the enlarged hole is important.