Search

Search

Search

Search

Increase asset recovery, improve wellbore quality, and reduce well construction costs with solutions that deliver precise drilling performance

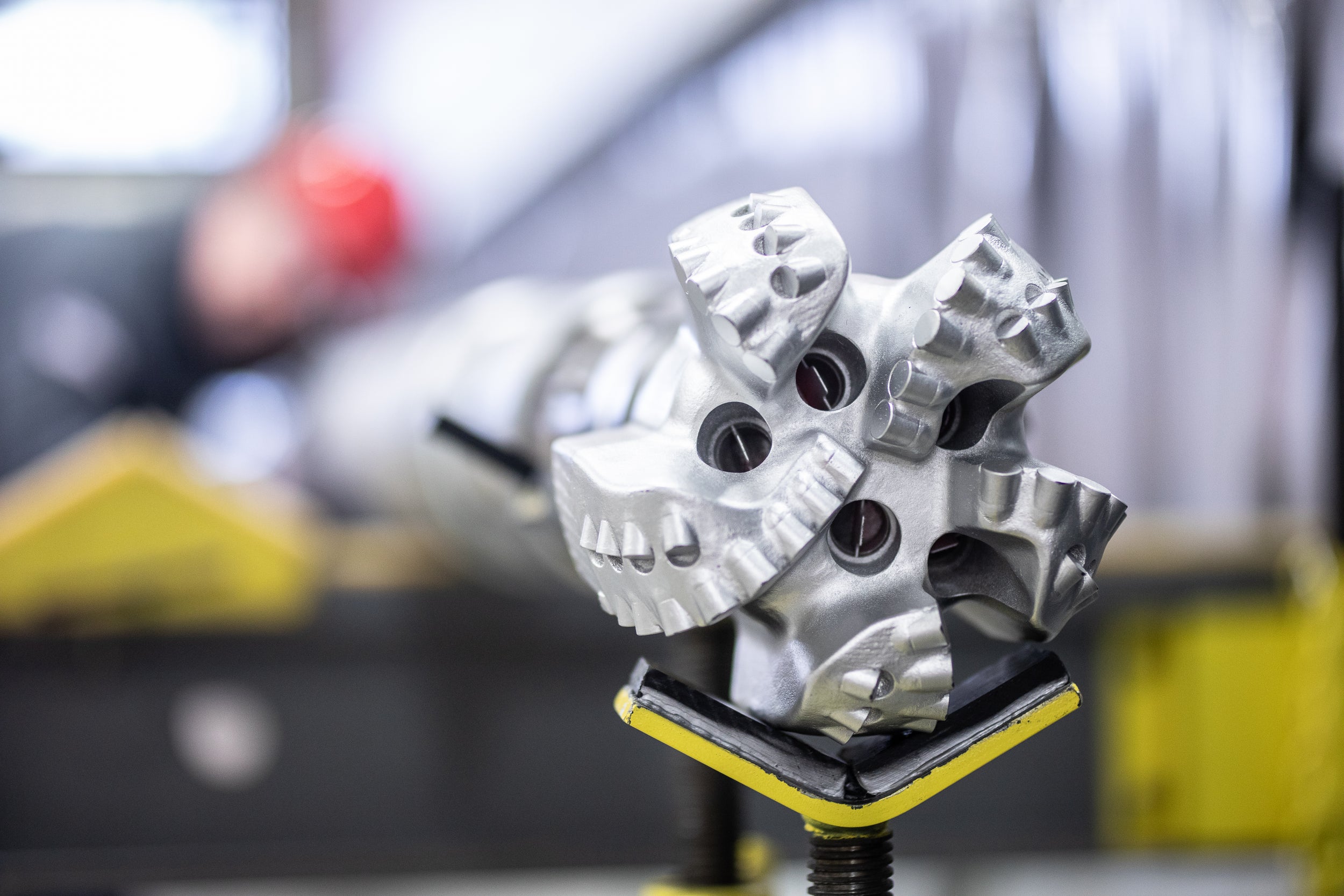

talk to an expertAchieve improved drilling optimization and performance with customized drill bits, in-bit sensors, and advanced rotary steerable systems. Halliburton’s innovative technologies reduce well time, increase the rate of penetration, and optimize bit performance throughout runs. We custom-engineer drill bits for your specific formation challenges. Our rotary steerable systems navigate complex well profiles with precision. In-bit sensors collect real-time data to help optimize performance as you go.

Increase in producible reserves

Reduction in overall project timelines

Fewer well control incidents

Reduction on well construction costs

Maximize asset recovery with advanced geosteering technologies that ensure precise well placement. We engineer drilling solutions that allow you to drill faster in difficult formations, such as our rotary steerable system and the gyro-while-drilling service. This reduces drilling time and maximizes reservoir contact.

Real-time downhole data enables you to make timely decisions and adjustments for accurate well placement. When combined with our drilling systems, you gain reservoir knowledge, more control over difficult environments like deepwater, and minimize downhole losses. We help you increase producible reserves, improve production rates, and enhance overall field recovery factors.

icruise x intelligent rotary steerable system

By automating your drilling process, you can maximize asset value through reduced well time, fewer rig site personnel, and lower costs per BOE while achieving predictable, reliable results in the most challenging conditions.

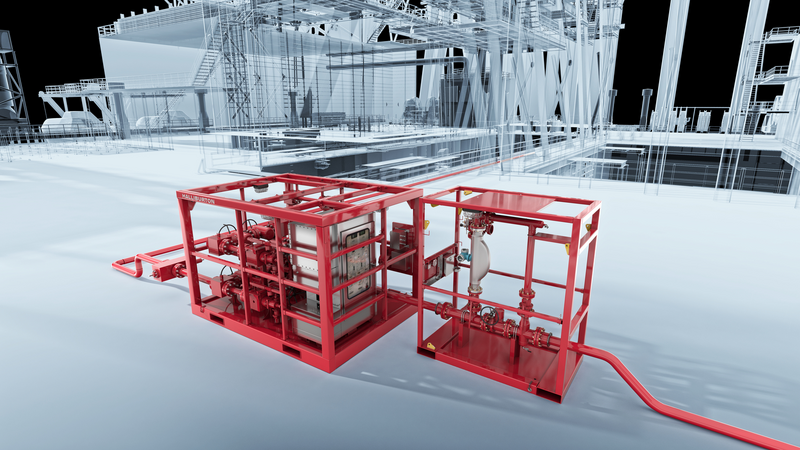

explore icruise xAchieve significant cost savings in your drilling operations with integrated drilling technologies and efficient pipe recovery solutions. Seamless integration of advanced tools, digital platforms, and automation helps minimize operational costs through faster penetration rates, reduced non-productive time (NPT), and fewer required trips. Predictive maintenance powered by AI ensures equipment reliability, which reduces downtime and extends the lifespan of your machinery.

We help you improve your capital efficiency, which gives you a competitive edge as you develop resources. Our integrated services allow for unified coordination among our drilling solutions, from drill bits and fluids to directional drilling and well evaluation.

Attain enhanced well control and risk mitigation with our comprehensive well control solutions and 24/7/365 emergency response services. We use advanced pressure prediction and management technologies and customized well control equipment and procedures tailored to your specific needs. This helps you enhance your safety record and reputation, reduce well control incidents, and minimize costly downtime and potential environmental damage.

case study - ecuador

First GeoTap® IDS formation pressure testing service provides key information to understand reservoir compartmentalization in deviated well and reduces rig time.

read case studycase study - oman

Discover how nano technology additive improves drilling performance, delivers wellbore stability in hard rock formation, and reduces drilling time by 7 days.

read case studyHalliburton pushes the boundaries of drilling technology to help operators maximize asset value, improve wellbore quality, and reduce overall well construction costs. Our cutting-edge tools, automation, and digital platforms deliver precise performance that sets new industry standards. We continue to develop new technologies and solutions, such as high-performance fluid systems and nanotechnology additives for improved wellbore stability, that offer exceptional performance.

We combine our tools with local expertise to deliver tailored solutions for your projects. Dedicated account managers, technical support teams, and strategic partnerships help ensure your projects are executed seamlessly. Our global reach allows us to adapt our technologies to specific geographical challenges. We help operators drill faster, more accurately, and more efficiently than ever before and are shaping the future of energy exploration and production around the globe.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations.

Directional drilling systems engineered to reduce well time and maximize reservoir contact from unconventional land to extended-reach deepwater drilling.

Fixed cutter and roller cone bits are engineered to optimize performance by using our global network of engineers to design the right bit for the right application.

Halliburton delivers superior drilling performance to reduce time to first oil, enhance reservoir knowledge, and maximize production.

Navigate challenging pressure windows between pore and fracture pressure in complex wells to reduce drilling days and NPT.

Cost-effective solutions recover pipe when it’s time to abandon a reservoir allowing you to achieve your recycling, scrap, or regulatory goals.