Search

Search

Search

Search

Wellspot™ active magnetic ranging system used to bypass fish, precisely align sidetrack, and save pad

Download PDFMature Field

Accurately align trajectory, re-enter wellbore, and regain control

Colorado

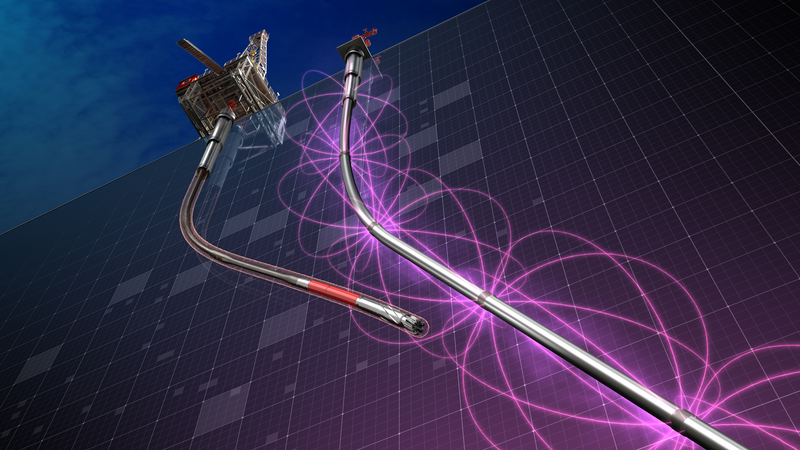

While an operator drilled the first well of a multi-well pad and reached TD at approximately 12,000 ft MD, the BHA assembly became differentially stuck while tripping out of the hole (the bottom of the fish was located at 5,055 ft MD). For weeks, the operator attempted various fishing attempts with no success. Following instruction from a third-party ranging provider, the operator backed off the fish (top of fish at 4,923 ft MD), cemented back to sidetrack, and re-entered the open hole. Two resultant sidetrack attempts to re-enter the original wellbore were unsuccessful.

The oil and gas regulator advised the operator that the original wellbore must be re-entered for the remainder of the pad. Based on extensive experience in wellbore re-entry, the operator recruited Halliburton to replace the original directional and ranging provider.

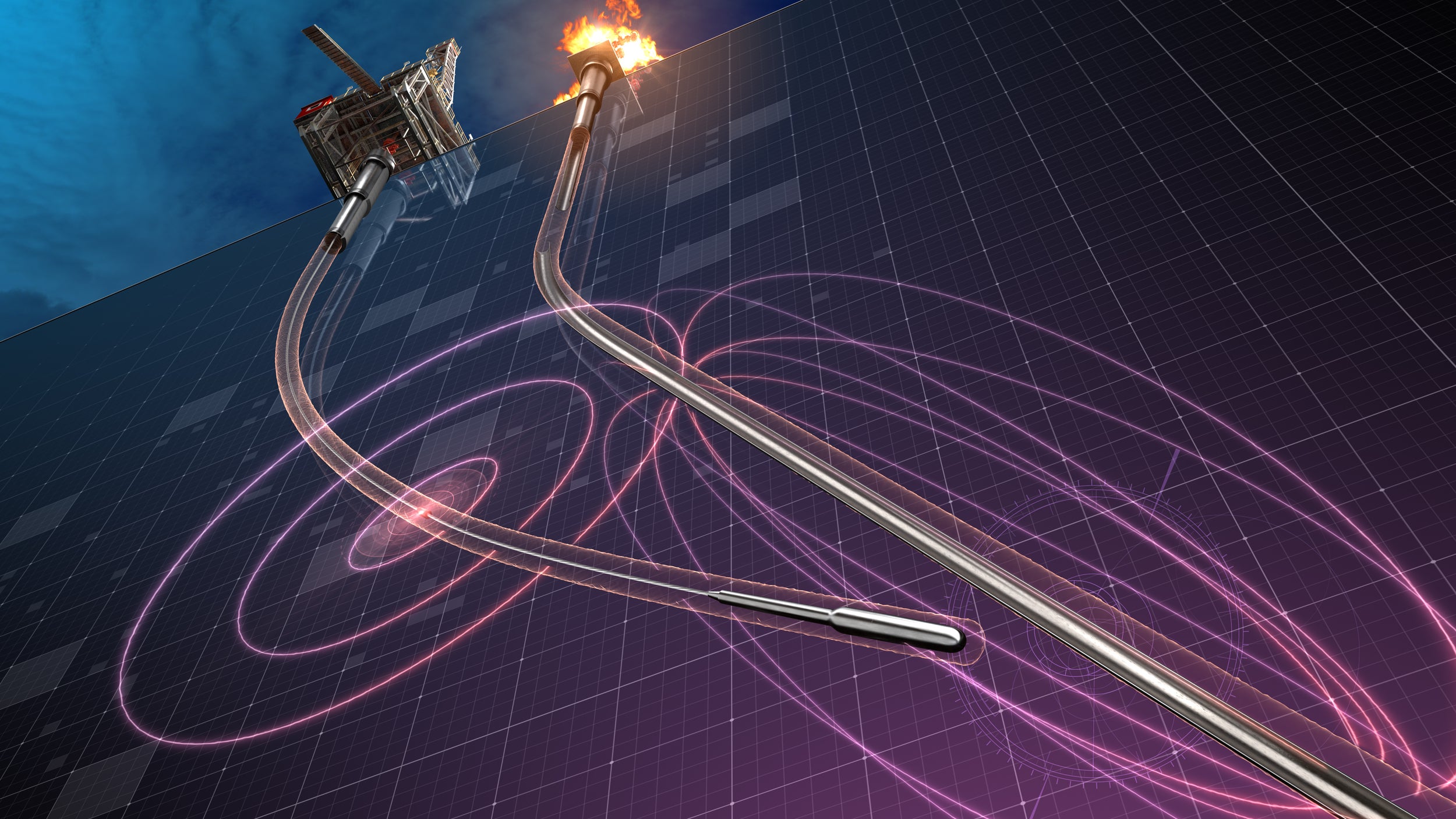

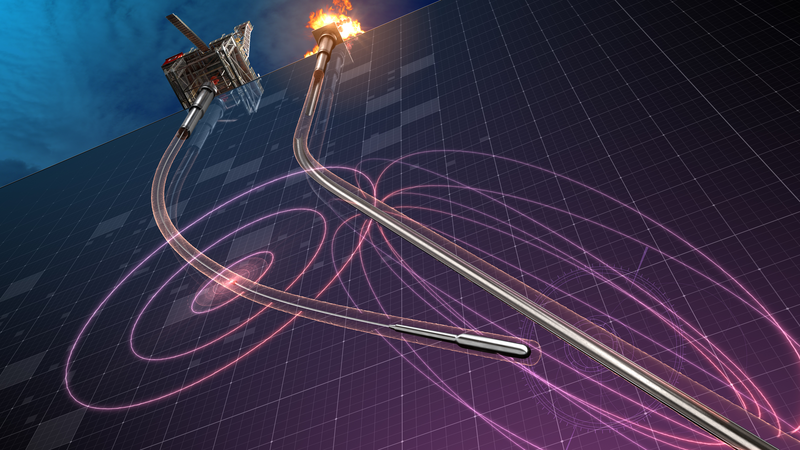

Halliburton deployed the WellSpot™ active magnetic ranging system to successfully detect the fish; however, the surveyed position revealed the target was outside the EOU outlined by the original MWD surveys. After a sidetrack, the WellSpot ranging system was used to improve the target’s surveyed position by more than 8 ft, which allowed the operator to regain access to the original wellbore.

The challenge of openhole re-entry is the limited number of tubulars to generate a magnetic signal to conduct ranging operations. Active magnetic ranging induces a distinct magnetic field, which is then detected by its sensors. By analyzing the magnetic signature of the fish, an optimal trajectory was determined, and the well was re-entered.

The original surveys, confirmed by an external MWD service, differed from Halliburton’s WellSpot™ active magnetic ranging system findings, placing the fish outside the expected operational area (EOU). This discrepancy challenged directional control, yet Halliburton’s adjustments to the WellSpot system facilitated a successful trajectory for re-entry into the inactive wellbore.

Improvement in target’s surveyed position

Success record in accessing wellbores

By re-entering the open hole, the operator salvaged the dormant wellbore and was able to run production equipment to bottom with no issues.

The openhole re-entry appeased the oil and gas regulator and protected the open hole below the fish. The regulator then granted the operator permission to drill the remainder of the multi-well pad.

This marks the third successful use of the WellSpot system for openhole re-entry beyond a fish, maintaining its 100% success record in accessing wellbores.

Magnetic ranging solutions demonstrate a well-established history of expertise, proving our dedication to precision when navigating the intricacies of well proximity applications

WellSpot™ active magnetic-ranging systems use precise sensors to provide data for multiple drilling applications.

The Passive Magnetic Ranging (PMR) service utilizes the remnant magnetic fields on target well tubulars to provide a distance and direction between wellbores.