Search

Search

Search

Search

First GeoTap® IDS formation pressure testing service provides key information to understand reservoir compartmentalization in deviated well and reduces rig time

Download PDFMature Fields

Resolve uncertainty about fluid types and contacts in highly deviated well

Ecuador

An operator in Ecuador devised a strategy to drill wells in an unexplored area of a reservoir to enhance production and potential reserves. They identified a compartmentalized reservoir. This discovery made hydraulic characterization of the production interval crucial to their plans. For one well, the approach involved a trajectory with high inclination along the reservoir interval.

After drilling two wells in an unexplored area of the field, the operator needed to establish mobility, determine fluid contact location, and create connectivity between geological units in the reservoir for the third well. The future well plan included a reservoir target at a high angle. This increases risk and rig time associated with pressure test data acquisition.

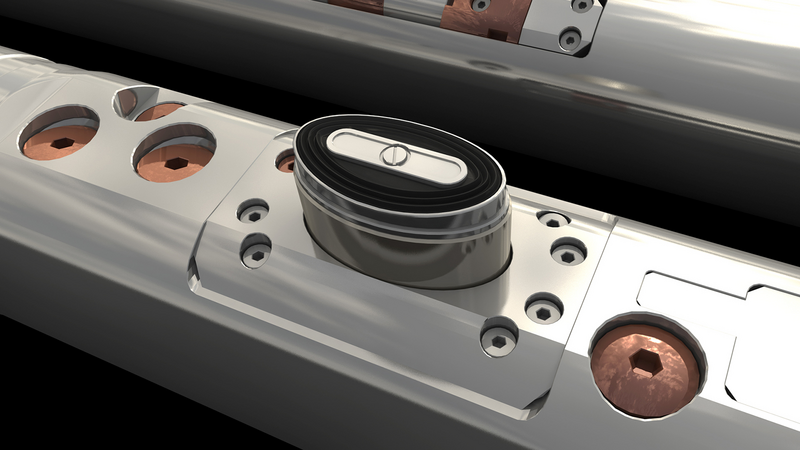

Halliburton recommended a pressure test data acquisition solution on the logging-while-drilling (LWD) bottom hole assembly (BHA) to acquire the necessary data and help minimize risk. The quad-combination BHA, GeoTap® IDS pressure testing, and fluid identification and sampling service were designed to estimate fluid mobility. This combination also helped calculate pressure gradients to determine the reservoir phase by measuring formation pressure and petrophysical evaluation in a single run.

pressure test points acquired in a single run

All 20 pressure points requested by the operator were measured. The scope spanned the entire reservoir and its various phases and stratigraphic components. High-pressure and high-mobility zones were identified in the main reservoir body. Gradient analysis identified two phases, water and oil. The stratigraphic bodies above the main reservoir, which were targets in previous wells, had low pressure, mobility, and permeability values. These results correlate with those obtained from quad-combo data through a detailed petrophysics analysis.

Acquiring pressure test data with wireline would have been a technical challenge and added cost for the operator due to the high-angle well trajectory crossing the reservoir. Halliburton proposed a quad-combo package, including the GeoTap® IDS service and iCruise® intelligent rotary steering system (RSS), to meet formation evaluation requirements and provide crucial information for reservoir development plans. As this was the first run with GeoTap® IDS service in the country, pre-job planning was vital for outstanding service delivery. Collaboration with the operator involved multiple meetings between the drilling, geology, and reservoir teams, and Halliburton to support directional drilling and logging feasibility. These meetings also covered BHA engineering, simulations, risk assessment, offset analysis, and formation test procedures.

A total of 20 pressure test points were acquired in a single run, addressing the operator’s requirements. The geology and reservoir teams received valuable information from the pressure test results, such as reservoir gradient and compartmentalization interpretation.

The team achieved a high directional drilling index (DDI) well trajectory to target total depth using a complex quad-combo BHA that included GeoTap® IDS service and the iCruise® intelligent RSS. They performed 20 pressure test points in a single run and acquired two pressure gradient zones without any HSE or SQ incidents.

Results from pressure tests allowed the operator to enhance the target reservoir understanding and make real-time decisions about current operations and subsequent completion plans.

Fluid identification and sampling solution.

Direct formation pressure measurements on-demand.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations

Gather real-time, high-quality data while drilling for improved subsurface insight, increased ROP, and enhanced wellbore stability.