Search

Search

Search

Search

Latest down hole generator-based tools reduce lithium dependency, increase efficiency, and optimize costs

Download PDFMature Fields

Reduce lithium use, improve efficiency, and reduce cost in Generator-based tools

Caribbean

The drilling team in the Caribbean had the desire to transition to a more efficient Bottom Hole Assembly (BHA). The goal was to reduce battery use through continuous improvement. This shift, incorporating the iCruise® intelligent Rotary Steerable System (RSS) and the iStar® intelligent drilling and logging platform, minimized environmental impact and optimized cost efficiency. The new BHA maintained high tool reliability and drilling precision, achieving 56 wells with incremental reduction in lithium quantity and battery usage.

The transition lowered material procurement and hazardous waste disposal costs while setting a new standard for drilling operations in the Caribbean. This approach balanced cost efficiency, operational excellence, and environmental responsibility.

The team faced the challenge of transitioning to a more efficient BHA while maintaining high drilling performance. Traditional BHAs relied heavily on lithium batteries, raising environmental and cost concerns due to lithium extraction and hazardous waste disposal. To address this, the team needed to reduce lithium dependence without compromising the precision and reliability of the downhole tools. This required a solution that could power multiple downhole sensors throughout the entire drilling process, both with and without mud pump circulation. The team sought a comprehensive approach that balanced performance, cost, and environmental impact, ensuring a successful shift to a low-lithium, generator-powered BHA.

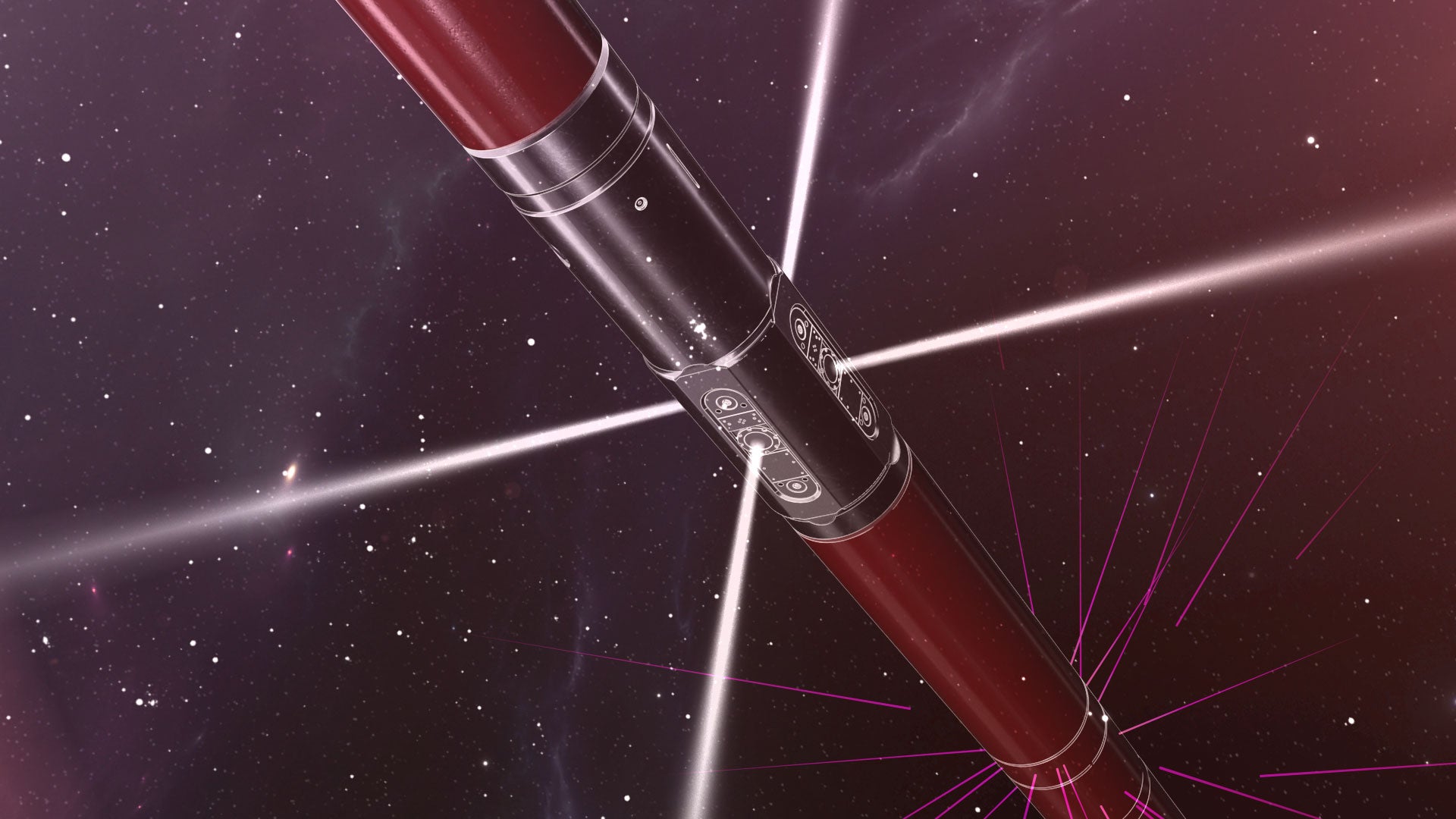

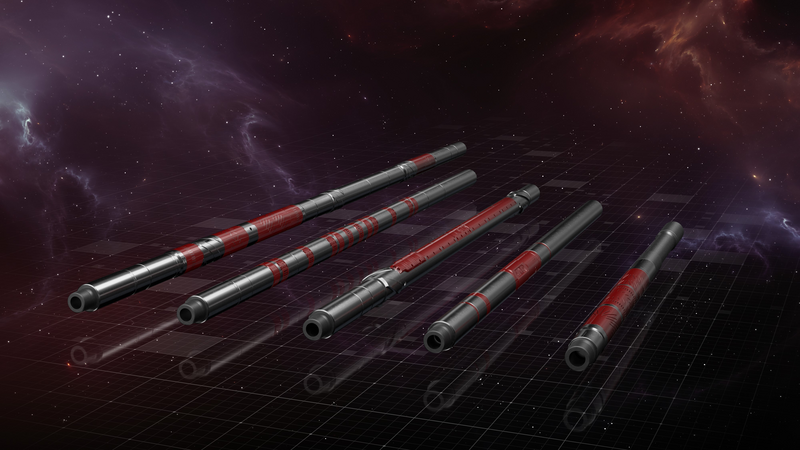

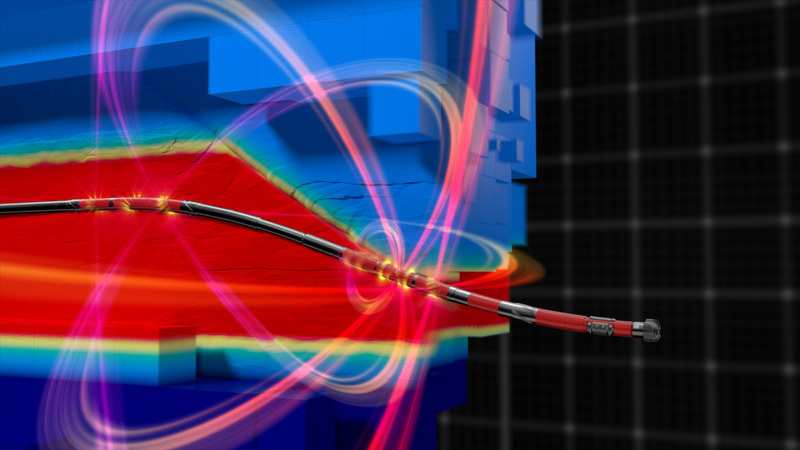

The team adopted a phased approach to transition to a more efficient BHA. They replaced the battery-powered rotary steerable system with the generator-powered iCruise® intelligent RSS. The BHA included the iStar® intelligent drilling and logging platform, which features efficient electronic components and non-critical sensors that power off when not circulating. The iCruise® RSS systems were modified to supply power to other LWD tools during circulation. Additionally, the telemetry system was upgraded to the generator-powered PulseStar® high-speed telemetry service, which replaced the previously battery-powered system. The Earthstar® X transmitter was also integrated into the iCruise® intelligent RSS.

Reduction in lithium use

Reduction in battery use

Wells

Recovery

The next-generation BHA, featuring the iStar® platform and PulseStar® high-speed telemetry service, resulted in operational and environmental improvements. The low-lithium, generator-powered BHA reduced lithium usage by 55% and battery use by 54%, minimizing environmental impact and aligning with global initiatives. This transition also lowered material procurement and waste disposal costs while maintaining high tool reliability and drilling precision. By adopting this innovative BHA, the customer set a new standard for drilling operations in the Caribbean, balancing cost efficiency, operational excellence, and environmental responsibility.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere

The PulseStar™ intelligent, high-speed telemetry service streams high-resolution, real-time drilling and subsurface data at any depth to ensure efficient and consistent well delivery

Near-bit, shallow, and ultra-deep resistivity service that enables accurate reserves evaluation to help place wells in the productive zone of the most complex reservoirs.