Search

Search

Search

Search

Completed a 6,000 ft. section, achieving the longest RWD run to date in the Middle East and second longest run globally.

Download PDFUnconventionals

Ream while drilling in large hole facing harsh drilling conditions

Middle East

Eni recruited Halliburton to perform its first reaming while drilling (RWD) operation in a 17-1/2 × 19 in. hole in an offshore well in the Middle East.

Eni faced several potential challenges in this unconventional environment composed of interbedded layers, including the potential for PDC bit ring out, excessive downhole vibration, mud weight up to 15.2 lbm/gal with 25 to 35% solids, and formation deformation and collapse. In addition, cementing challenges attributed to irregular hole gauge through salt and various other casing stresses.

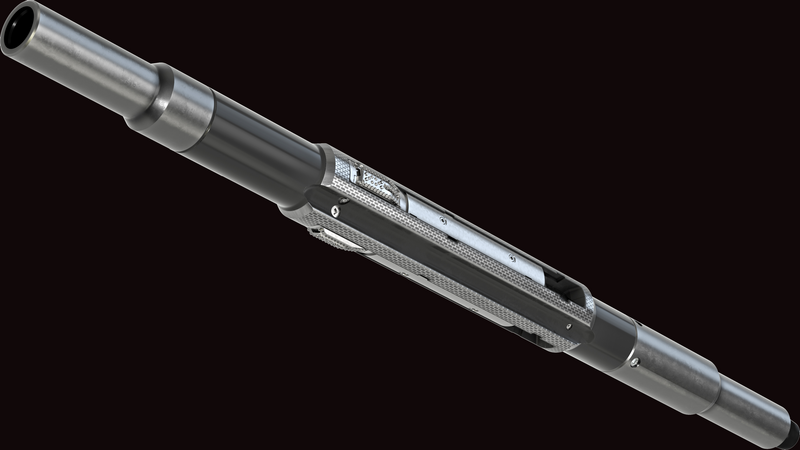

To achieve success in this severe drilling setting, Halliburton pulled from its vast technology portfolio to develop a custom RWD solution for the operator. This included a 1600 × 19 in. XR Prime™ reamer hole enlargement tool with a newly designed arm to match the bit. The reamer was used in combination with the iCruise® rotary steerable system and a vibration-dampening tool. Eight seven-blade bit designs were utilized with dual row Geometrix® 4D-shaped Machete™ cutters. Precise Bit Reamer software helped optimize performance in addition to 24/7 real-time ADT® drilling optimization service.

The hole was safely enlarged without affecting rate of penetration (ROP) or vibration performance. The bottom hole assembly (BHA) was securely retrieved, and the liner successfully reached total depth, reducing rig days. Eni completed a 6,000 ft. section, achieving the longest RWD run to date in a large hole across the Middle East and the second-longest RWD run globally. Average ROP was 25.7 fph and on-bottom ROP was 33.7 fph in the openhole interval, approximately 43% higher than expected. The bit and underreamer arm remained in perfect condition throughout the operation and total delivery time and well costs were reduced. Overall, the operator was extremely satisfied with the performance of the RWD operation in this field, further strengthening its partnership with Halliburton.

Higher ROP than expected

Feet

The XR Prime™ reamer hole enlargement tool provides extreme durability and stability in the most challenging applications.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs