Search

Search

Search

Search

Maintain well integrity, improve output, reduce costs, and bolster operational efficiency with engineered well completion solutions

Talk to an expertHeterogeneous reservoirs pose challenges for operators as they struggle to maximize production from each zone. Operators must maintain fluid flow across rock properties such as permeability and porosity that vary across different zones. Additionally, they must accurately characterize these reservoirs, improve resource recovery, and avoid water and gas breakthrough.

With an expansive portfolio of solutions that cover every phase of the completions process, Halliburton’s intelligent completions provide operators with precise control and monitoring to optimize production across the entire wellbore. Operators can adjust flow rates in real-time, which improves overall reservoir performance and recovery. Real-time data collection and monitoring help operators gain deeper reservoir behavior insights. Variable setting valves improve recovery with sequential production schemes or commingled production enablement.

Intelligent completions allow operators to remotely control and isolate problem zones, which helps manage water and gas influx. In turn, operators can extend the life of the well, reduce the need for costly well interventions, and increase recovery.

Operators must control well pressure to prevent blowouts, wellbore collapse, or other safety hazards. However, the process of fluid extraction creates pressure fluctuations. These become even more pronounced as the various rock properties in complex wells lead to uneven fluid flow and pressure distribution.

Our well completion design incorporates advanced pressure management systems and intelligent completions that allow operators to continuously monitor and control wellbore conditions. Advanced monitoring capabilities allow operators to detect small changes in well conditions, such as scale buildup, and act quickly. The ability to configure wells remotely helps avoid the need for well interventions. This saves time and costs associated with workover operations.

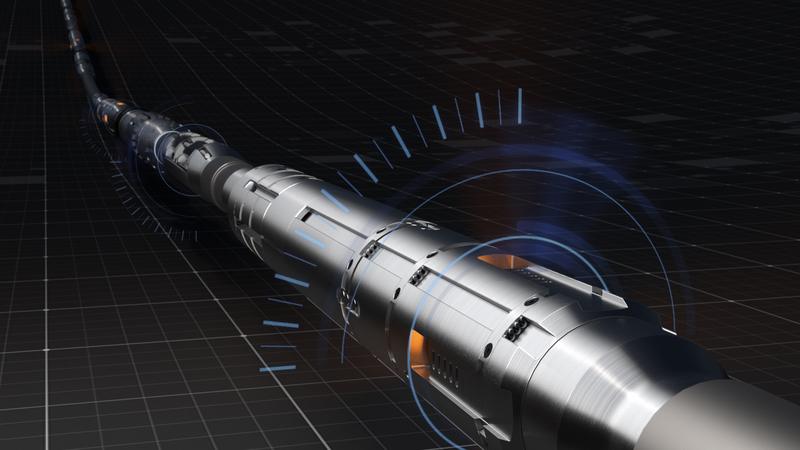

Sand production in reservoirs causes erosion, clogs, and damage to well equipment. Halliburton provides comprehensive sand control solutions as part of our well completion process. This includes advanced completion tools and technologies designed to mitigate sand production. These tools enable real-time data collection and analysis. When operators detect excessive water or sand, they can shut in problematic zones.

Specialized downhole equipment includes gravel pack packers and screens. Inflow control devices help delay and reduce the flow of unwanted fluids and protect the integrity of the wellbore.

Operators need to minimize rig time and operational costs while maximizing well performance. As oil and gas markets fluctuate, they require the ability to manage costs associated with exploration, drilling, production, and infrastructure development.

Halliburton’s intelligent completions and advanced well completion designs improve operational efficiency through the enablement of simultaneous operations. This reduces rig time and optimizes how operators utilize resources, which leads to significant cost savings and improved profitability.

case study - middle east

Discover how Halliburton set a record with the successful installation of a 12-zone intelligent completion for an operator in the Middle East. This installation doubled the number of zones Halliburton has completed in a single well.

read case studycase study - caspian sea

A major operator in the Caspian region required pressure support and sweep efficiency for enhanced recovery of a massive offshore oil field. Previous attempts at multizone, high-rate water injection in this soft sand field had mixed results. Explore how Halliburton installed the world’s first 10,000-psi triple-zone, intelligent completion for water injection.

read case studyThroughout production, operators need access to accurate, real-time data to make informed decisions about well operations. They need the ability to respond quickly to well integrity issues or risks to help avoid production issues and cost increases.

Halliburton’s intelligent completion solutions provide real-time data insights, automation, and remote connectivity. Operators glean actionable insights from the data to optimize well performance and production and streamline work processes.

Consistent service quality in well completions is crucial. Without it, operational inefficiencies, safety risks, and poor well performance can arise. Additionally, the likelihood of breakdowns, downtime, and costly delays increases, along with potential safety hazards like compromised well integrity.

In addition to the largest portfolio of solutions to meet a variety of completions requirements, Halliburton adheres to the highest standards for service quality. Our approach includes:

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.

Achieve greater profitability and a higher return on investment with innovative multilateral technology

Versatile, dependable, field-proven packers for every type of well completion.