Search

Search

Search

Search

Revolutionizes subsea safety with electric actuation

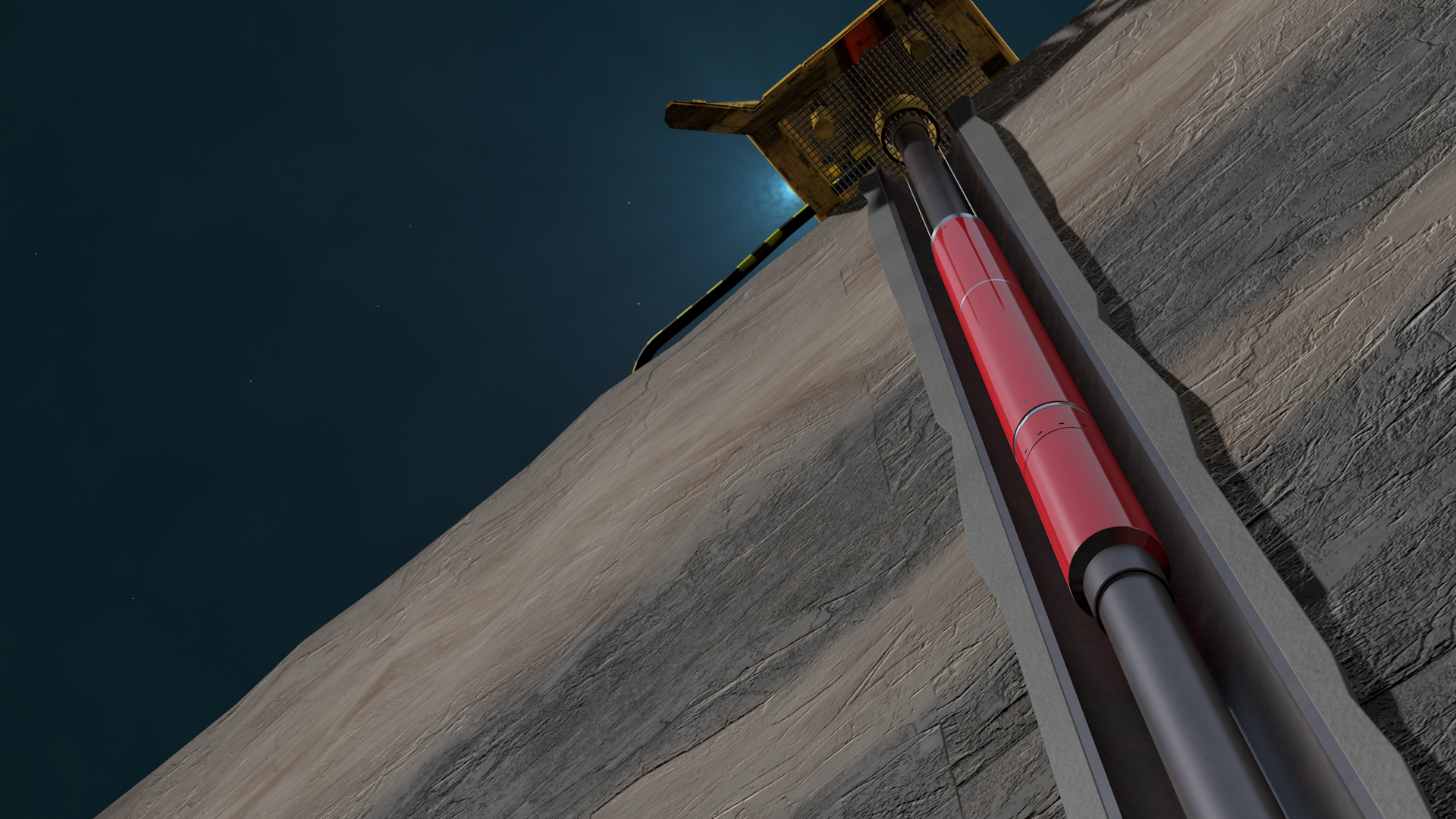

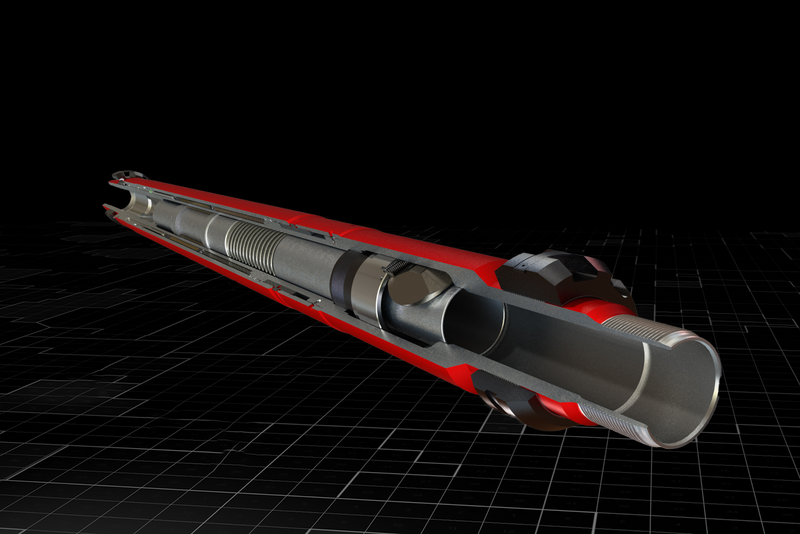

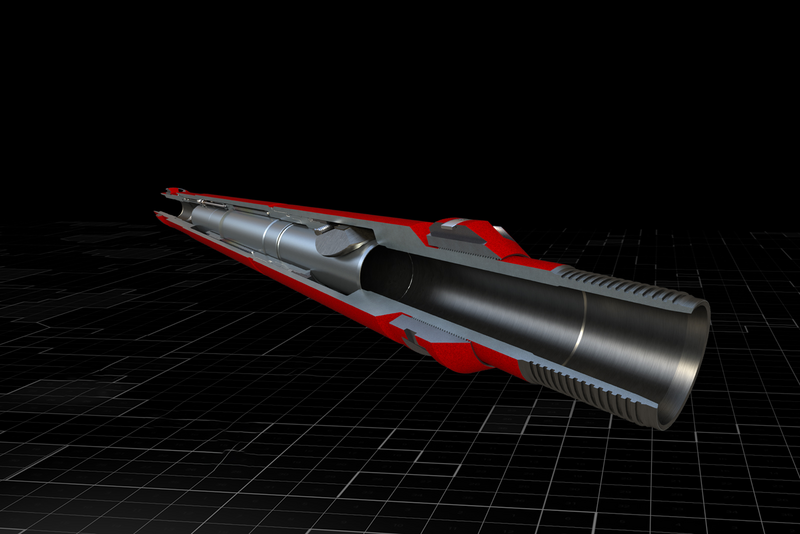

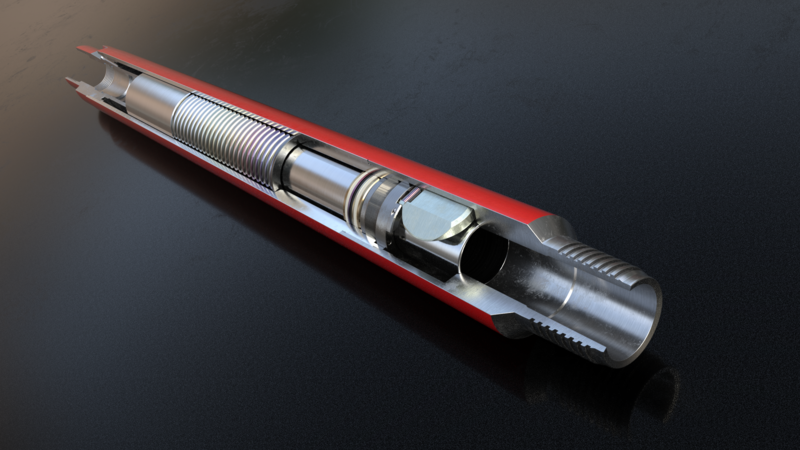

Talk to an expertHalliburton's EcoStar® eTRSV is the world’s first, field-proven electric tubing-retrievable safety valve (eTRSV). First installed in 2016, the EcoStar eTRSV solves a 30- year industry challenge to remove hydraulic actuation and its limitations.

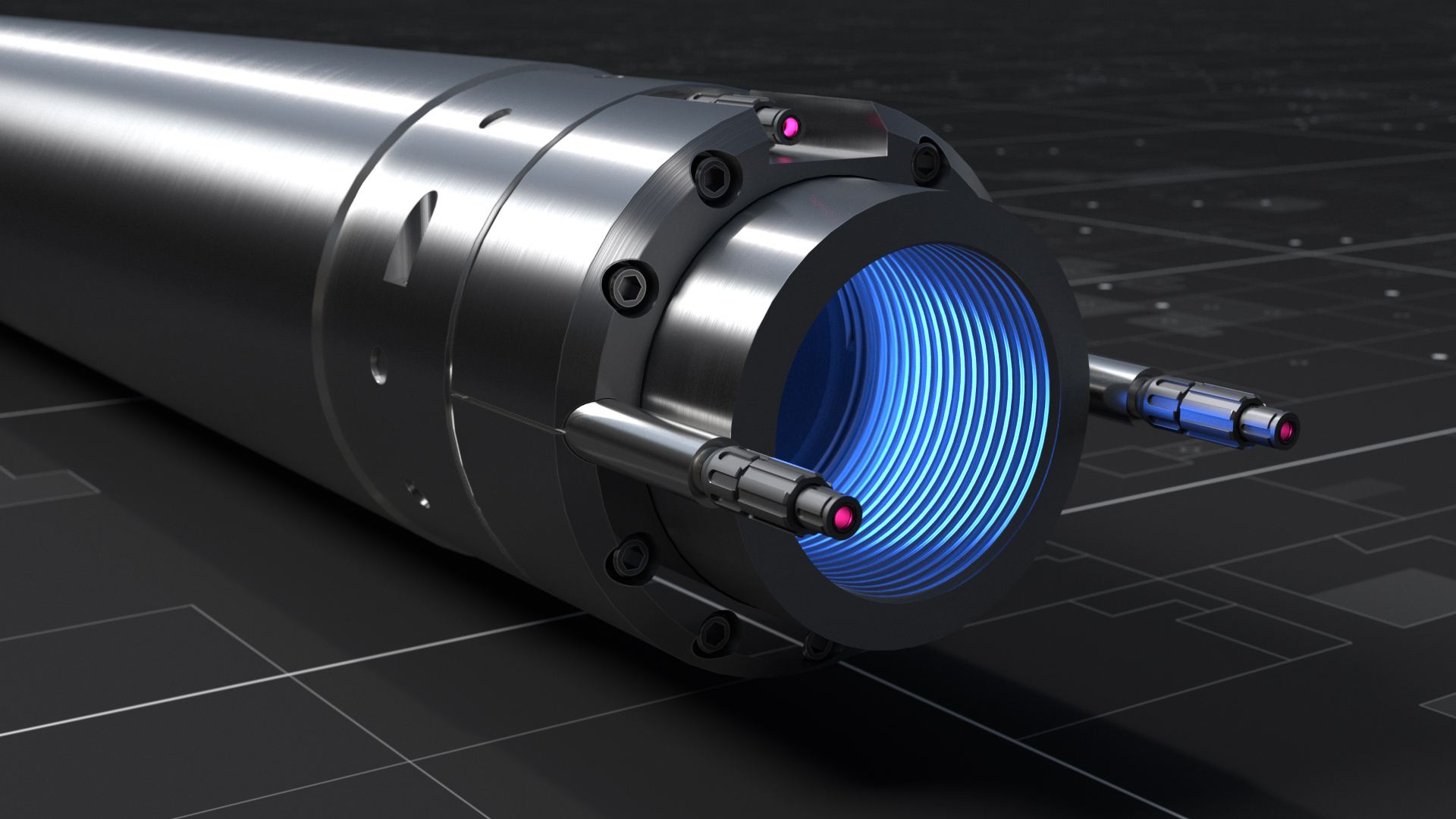

This breakthrough in electric actuation is made possible through a unique magnetic coupling mechanism between the actuator and the safety valve. The design and construction of the valve creates a chamber for the downhole electronics and electric actuator outside of the wellbore.

This enables a fully electric completion system with zero risk of exposing electronics to produced wellbore fluid and the added benefit of serving as a conventional safety valve with the same trusted fail-safe mechanisms.

World Oil Article

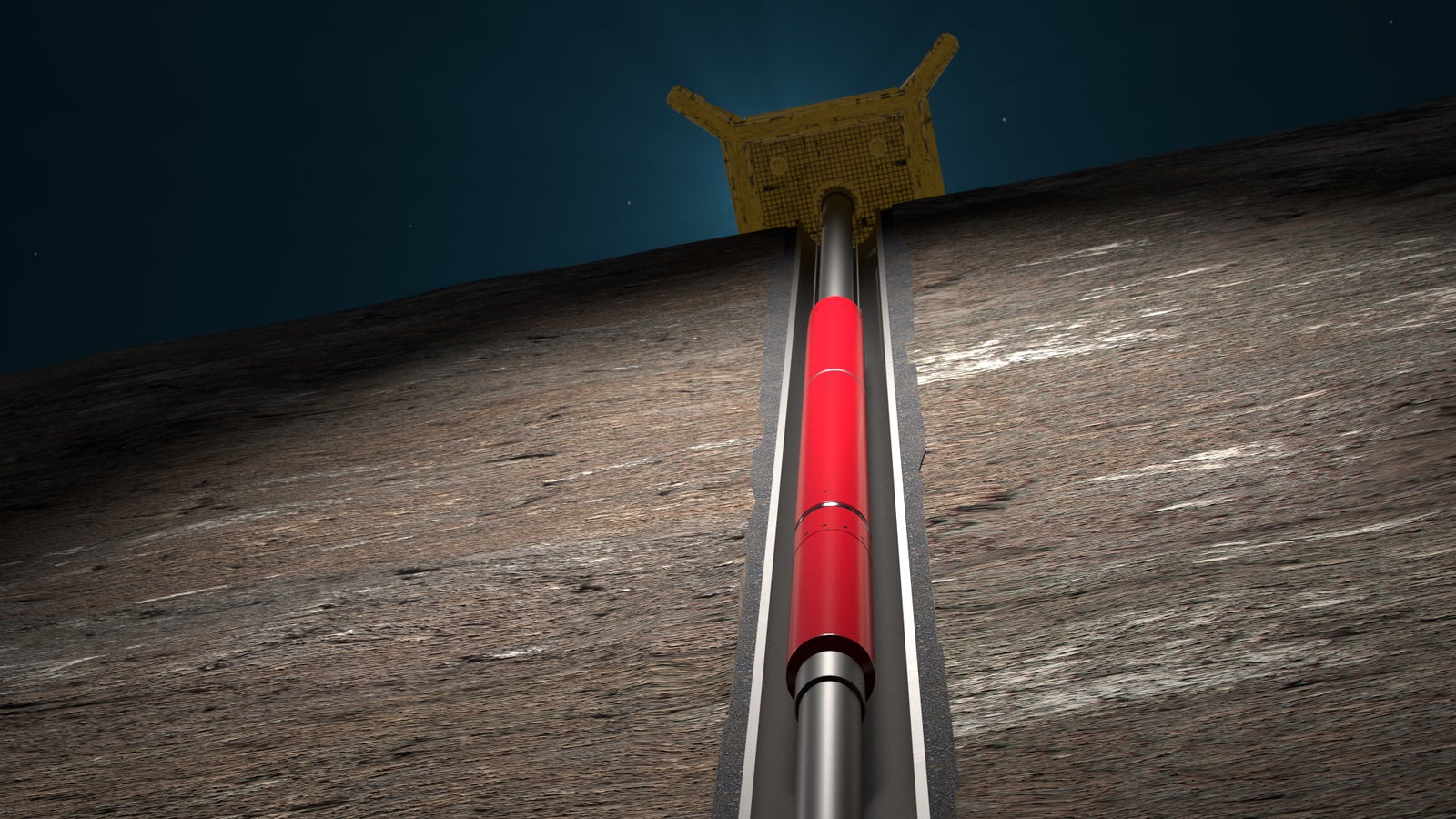

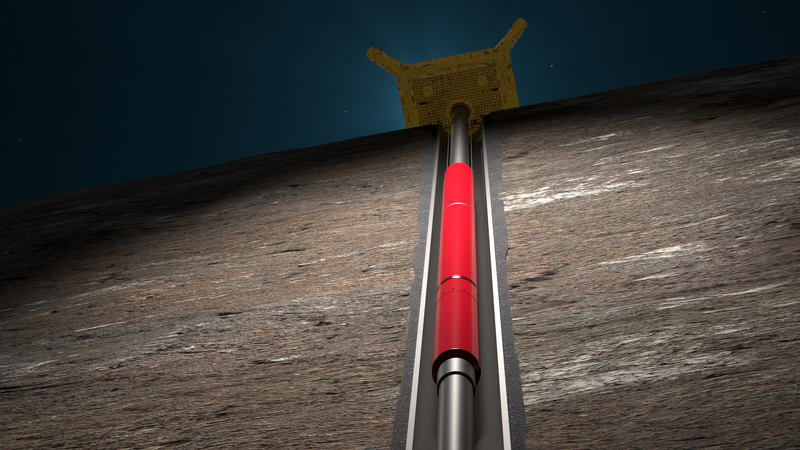

Read articleWith fully-electric actuation, the EcoStar eTRSV is easier to implement in deep waters and long tiebacks than hydraulic systems.

The world's first and only field-proven electric tubing-retrievable safety valve.

02:17

Read press releaseAs part of Halliburton’s all-electric portfolio, the EcoStar eTRSV marks another step toward the full electrification of wellbores.

Helps to eliminate setting depth constraints, increase reliability, and reduce capex.

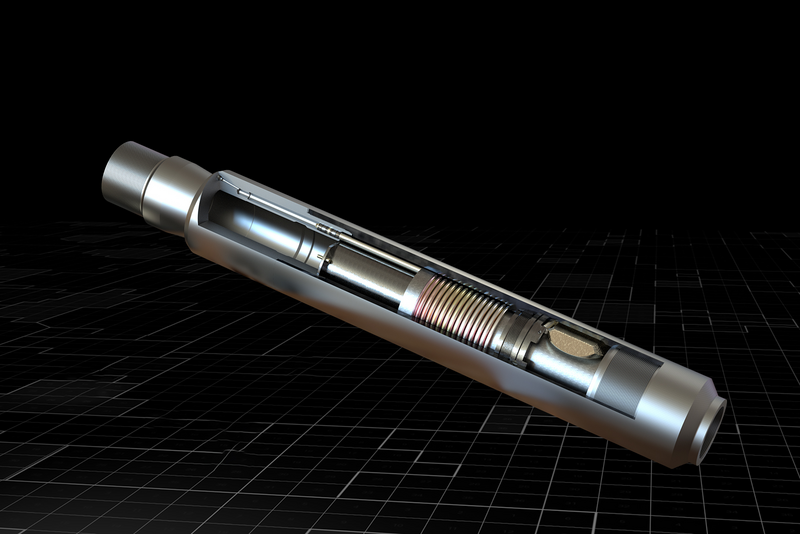

The Halliburton EquiStar® TRSV is a tubing pressure insensitive, non-equalizing, flapper-type safety valve that shuts down a well at a point below the surface.

A single rod-piston non-elastomer flapper valve designed for general production with enhanced reliability and long life.

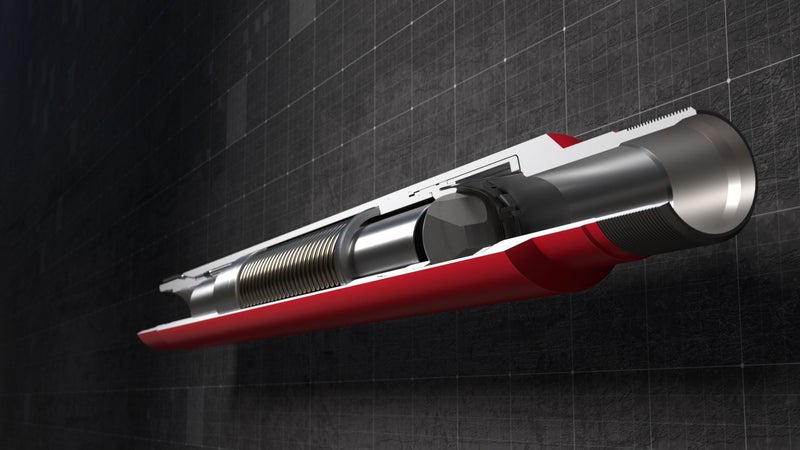

The NeoStar TRSV is a single-rod-piston, non-elastomer flapper valve for hostile environments and extended-life applications where reliability is needed.

NeoStar CS TRSV retains the features of the legacy SP safety valve and is equipped with the ultralow temperature operation and survival capabilities for CCUS.

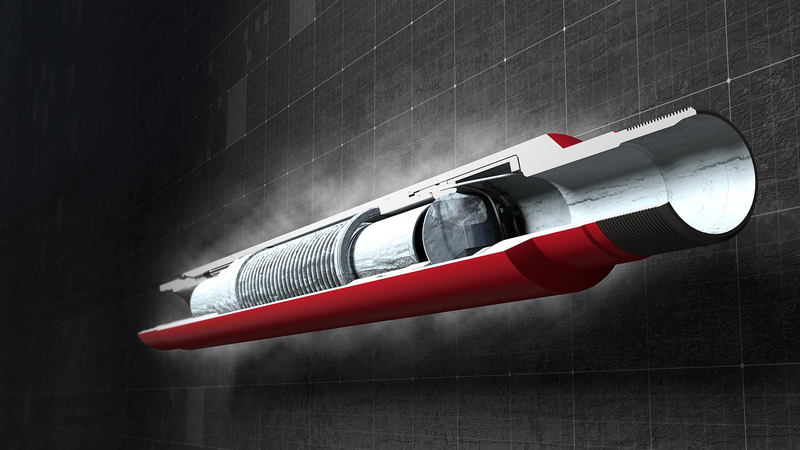

WellStar is a general production, hydraulically operated, downhole TRSV designed to enhances the valve’s overall reliability and provide trouble-free operation.

Halliburton tubing-retrievable and wireline-retrievable subsurface safety valves are a field-proven solution for operators.