Search

Search

Search

Search

Operator saves three days of potential remediation and eliminates NPT related to supplemental casing adaptors

Download PDFDeep Water

Welded restrictions discovered inside the casing string

Luanda

A major deepwater operator drilled offshore Angola for several years in an ongoing exploration campaign in two blocks. Although the operator had supplemental casing adaptors in its stock, nonproductive time (NPT) related to casing hanger issues was prevalent; thus, a reliable solution was necessary to allow the hanger to move safely through tight tolerances and casing anomalies. Halliburton installed the VersaFlex® Big Bore expandable liner hanger (ELH) system, which is known for its robust hanger and running tool. The installation was successful, and the liner was set to depth–the first such installation in Angola.

The Angola operator experienced NPT issues specifically related to supplemental casing adaptors. Welded restrictions were discovered inside the 20-in. casing. This presented concern because the liner hanger had to pass through a tight tolerance for more than 671 m (2,200 ft).

In addition to the robust liner system and reliable liner-top integrity, the operator required a high-quality cement operation that resulted in an effective formation integrity test and leakoff test. Expedited logistics were also necessary to deliver the components on-site in short notice.

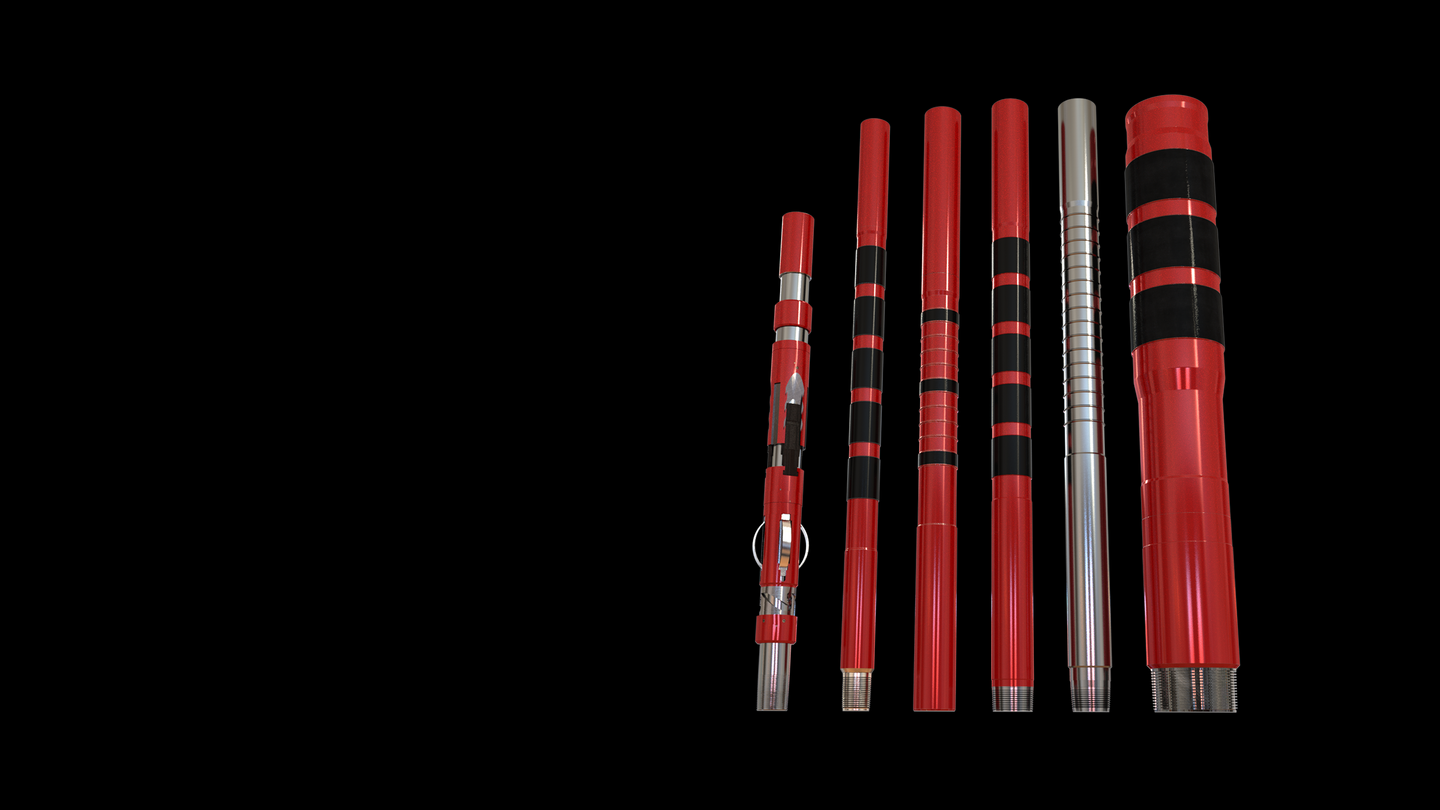

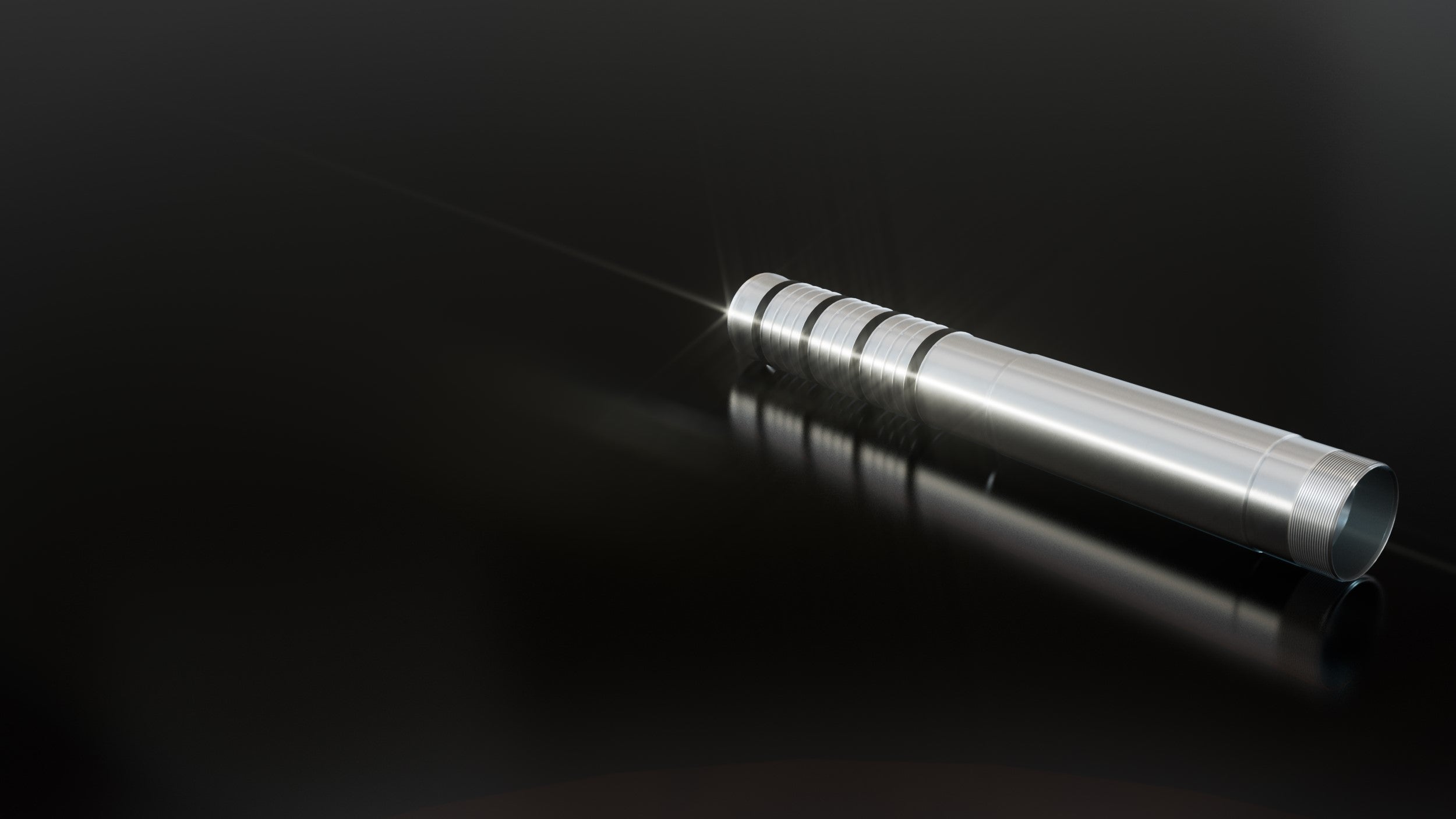

The VersaFlex Big Bore ELH system was a natural fit for this application because the tool provides a liner-top packer and liner hanger in a single trip. The smooth-form exterior allows the hanger to move safely through tight tolerances and casing anomalies. Additionally, unlike a casing hanger, the system can be set and sealed reliably anywhere in the parent casing, independent of, and without the need for, cement or a landing adapter to seat the hanger. Multiple sealing elements were preferred to the delicate external machined profile of the casing hanger. This provided unprecedented casing placement flexibility because it is not necessary to hang-off at the wellhead. The robust running tools can withstand more than 100,000 ft/lb of torque and can wash, ream, or drill the liner into position.

After thorough pre-job planning and careful examination of the casing between the operator and Halliburton, a VersaFlex Big Bore ELH system was installed in 1805 m (5,922 ft) of water depth from a drillship.

16 x 22 in. ELH in Caribbean

Objectives achieved

Hours of rig time saved

NPT

The VersaFlex Big Bore ELH system was deployed flawlessly without any safety and service quality issues. Most importantly, there was no NPT during the operation, and three days of remediation were potentially avoided. This saved the operator a significant amount of money considering the uncertainties and risks associated with deepwater operations.

With a 97.5% reliability performance rating, the VersaFlex Big Bore ELH system helped Halliburton achieve a benchmark for its first installation in Angola’s challenging deepwater environment.