Search

Search

Search

Search

World’s first 10,000-psi triple-zone, intelligent completion for water injection

Download PDFMature Fields

Multiple laminar sand packages require injection sweep

Caspian Sea

Halliburton advanced completion systems, including:

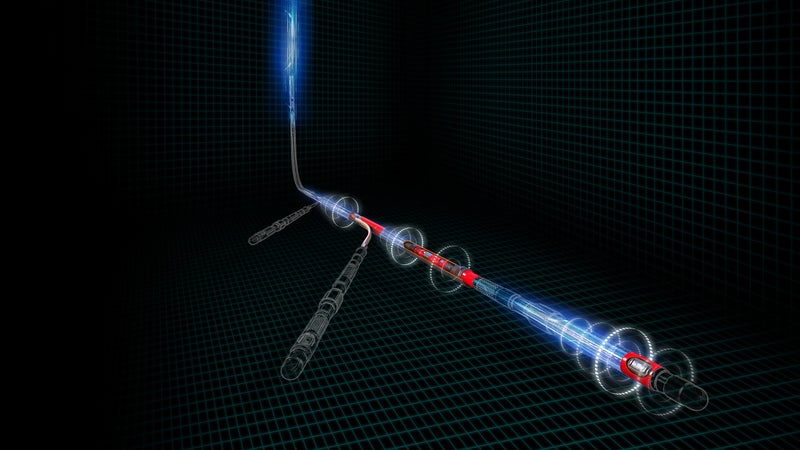

A major operator in the Caspian region required pressure support and sweep efficiency for enhanced recovery of a massive offshore oil field. Previous attempts at multizone, high-rate water injection in this soft sand field had mixed results. This included non-conformance injection profiles and loss of sand screen integrity, which led to sand infill and premature loss of zonal injectivity. Additional issues with interval control valve (ICV) reliability in early attempts caused by control line damage and a lack of custom automated topside control, also had to be addressed.

Effective remote control of the ICVs is required to successfully control injection conformance and mitigate potential downhole sand control issues attributed to an interruption in water injection, without traditional sand control equipment as part of the completion. Automated control is required to close one ICV or multiple ICVs during shutdowns performed because of topside equipment maintenance, well testing, emergencies, or loss of power.

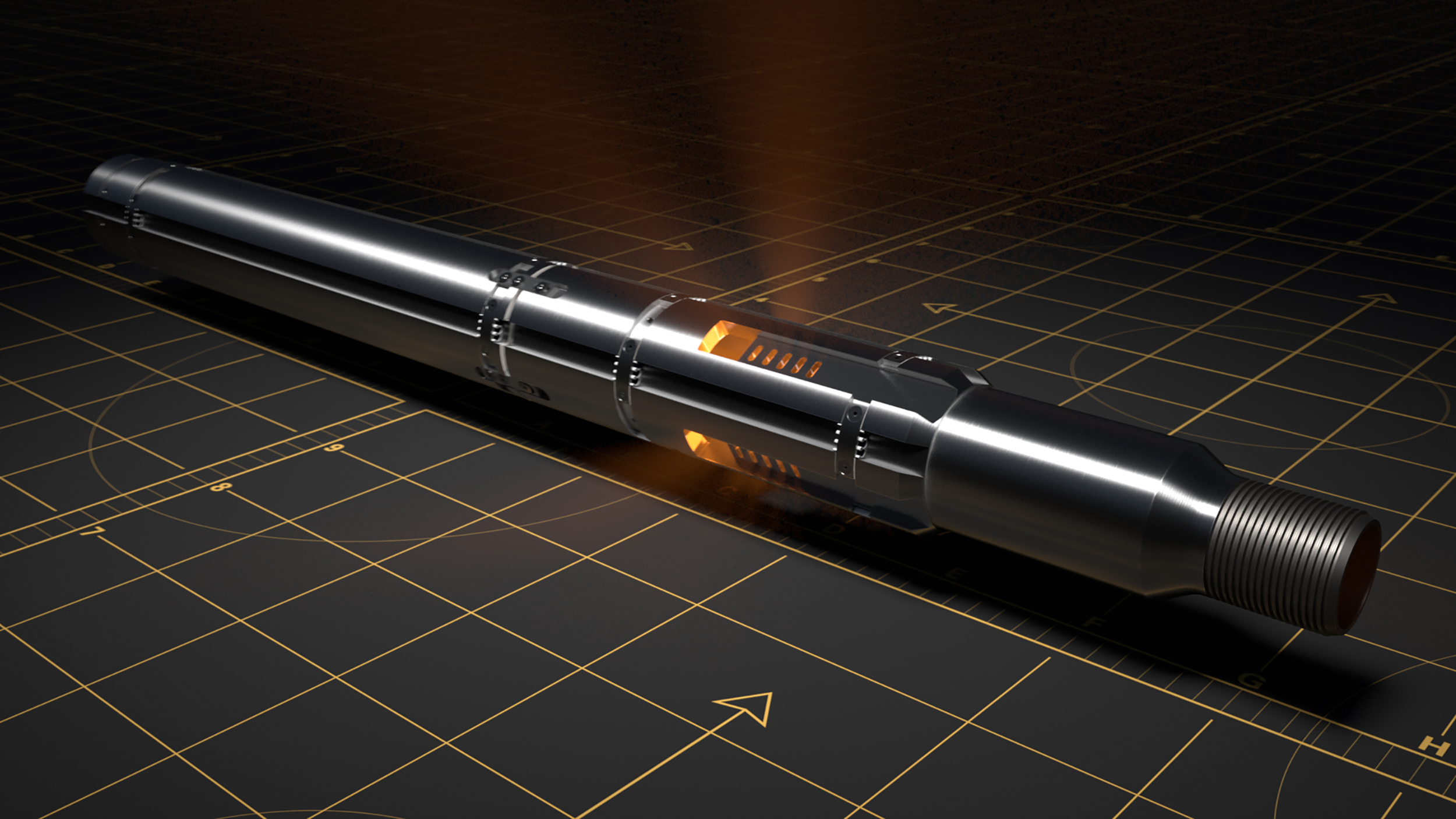

The Halliburton HS-ICV was selected for its custom flow trim, metal-to-metal (MTM) closure seal, enhanced control line protection for high-rate injection, and position sensor capability.

Over the course of a year, the discrete flow trim choke was customized with the operator’s reservoir goals in mind. Additionally, a comprehensive erosion study was completed that considered the operator’s need to inject unfiltered water with a high solids content through the completion of the life of the well.

The MTM closure seal is capable of 5,000-psi differential unloading, which is critical in a high-rate injection well for rapid startup after a shutdown sequence. Through 20 years of continuous improvement and lessons learned, the HS-ICV is equipped with enhanced control line protection for high-rate injection wells, which removes the control line from the turbulent flow path.

The ICV position sensor gives the operator the capability to quantify injection rates into each zone, knowing the discrete custom flow trim position, flow coefficient, and pressure drop from the ROC™ pressure gauge.

A surface hydraulic system (SHS) was developed with extensive hazard and operability (HAZOP) assessment, hydraulic accumulators, and a battery backup system, as well as software that is designed to automatically close ICVs during shutdowns. This rapid shutdown of ICVs mitigated the need for standard sand-control measures and decreased the risks of water hammer, sand infill, and zonal crossflow.

Zone water injection system

Wells

Zones installed

psi differential pressure injected

Halliburton installed an automated SHS that performed as designed for automatic ICV closure. This advanced completion solution is the world’s first triple-zone, 10,000-psi water-injection intelligent completion, and the injection flow rates exceeded the operator’s expectations. To date, a total of 56 zones have been installed in 18 wells

Halliburton intelligent completions technology help accelerate production and improve decision-making to increase ultimate recovery and maximize asset value