Search

Search

Search

Search

The wide selection of Halliburton chemicals and additives enables any slurry to be customized for the demands of each well.

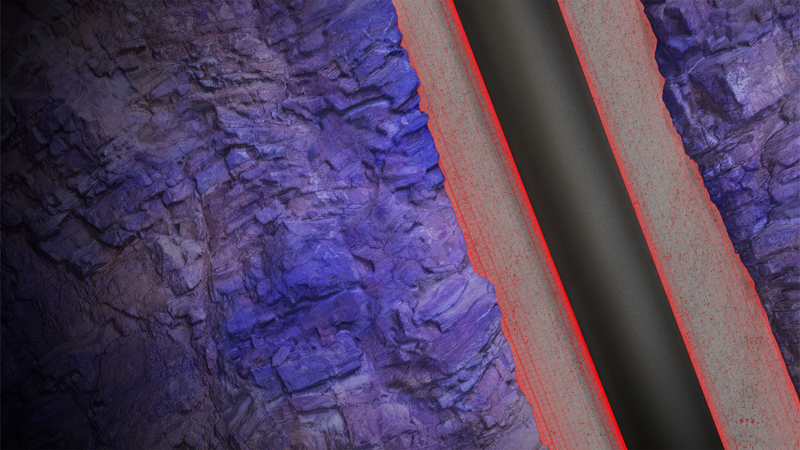

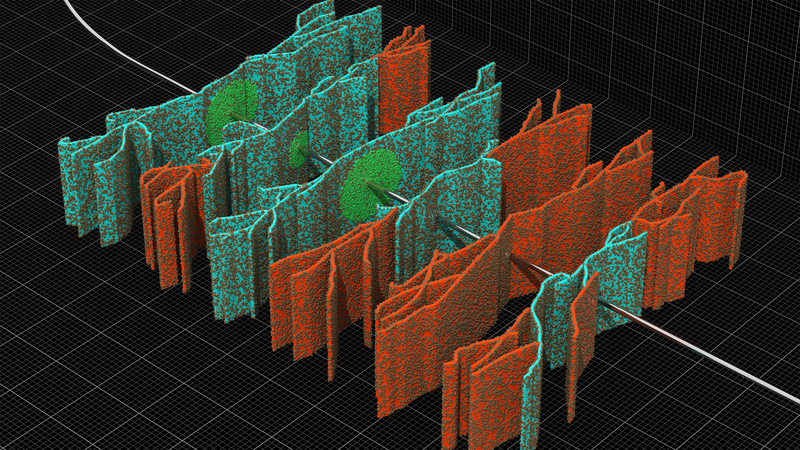

Talk to an expertHalliburton offers hundreds of chemical and additive solutions, including accelerators, dispersants, fluid loss agents, gas migration additives, latexes, retarders, and weighting agents. In addition to mitigating free fluid and reducing fluid loss, operators achieve a long-term tight annular seal and cement-sheath resilience for superior zonal isolation, even in technically demanding wells or environmentally sensitive areas.

Reduced Portland content helps customers lower carbon emission baselines and provides engineered systems with enhanced barrier performance.

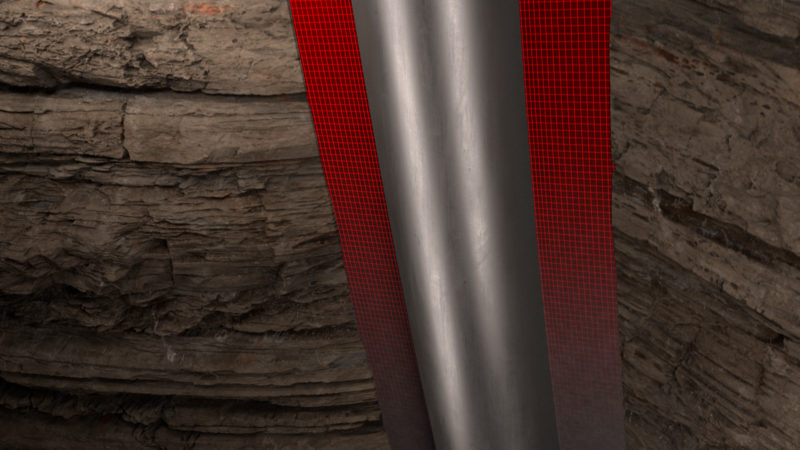

IsoBond™ cement system mitigates sustained casing pressure by managing gas migration and annular flow.

Provides enhanced resistance to CO₂, lower permeability, and increased elasticity in comparison to conventional Portland cement systems.

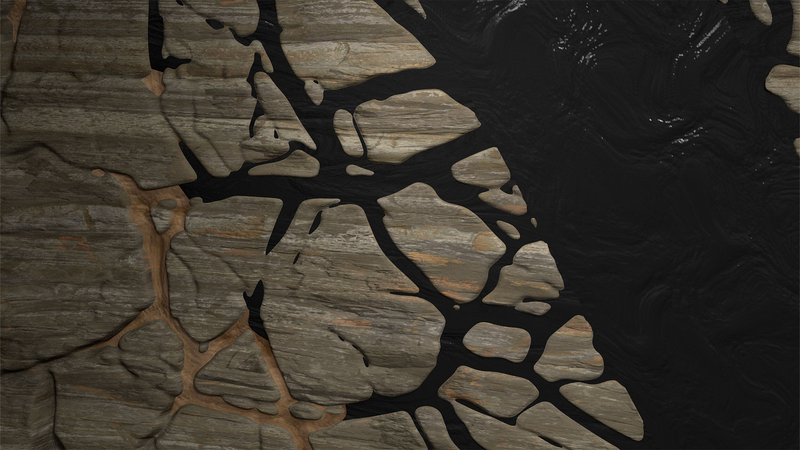

SentinelCem Pro is a unique, single-sack lightweight lost-circulation solution that enables proactive storage at the rig site to cure severe to total losses.

Tuned® Defense™ cement spacer systems prevent lost circulation while optimizing fluid rheology for effective mud displacement.

Improves cement spacer designs to prevent lost circulation.

BridgeBlend™ lost circulation material solutions use engineering design algorithms to customize locally available LCMs that address lost-circulation scenarios.

IsoGuard™ cement additive mitigates annular flow through unset cement by providing excellent fluid loss control and shortening transition time.

Swelling solution designed for barrier dependability and helps provide increased cement sheath elasticity.

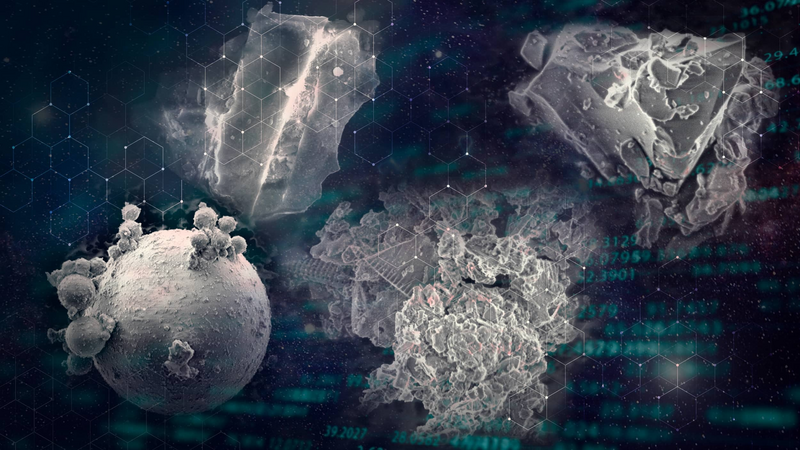

"We developed internal proprietary methods to measure the efficacy or functionality of a given material”

Going back to the basics of physico-chemistry

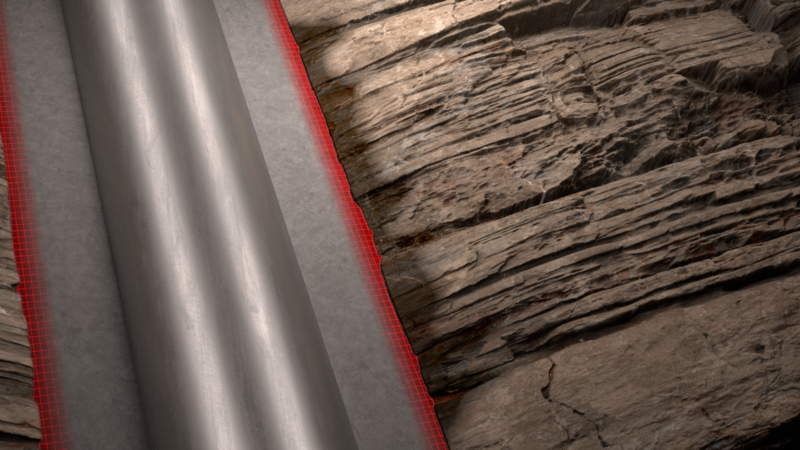

By examining how cement works at the molecular level, scientists at Halliburton created a lighter but stronger and more flexible cement for horizontal shale wells.

Read Article