Search

Search

Search

Search

Foamed Tuned® Spacer E+™ cement spacer success becomes operator’s top choice for future campaigns in Africa deepwater operation

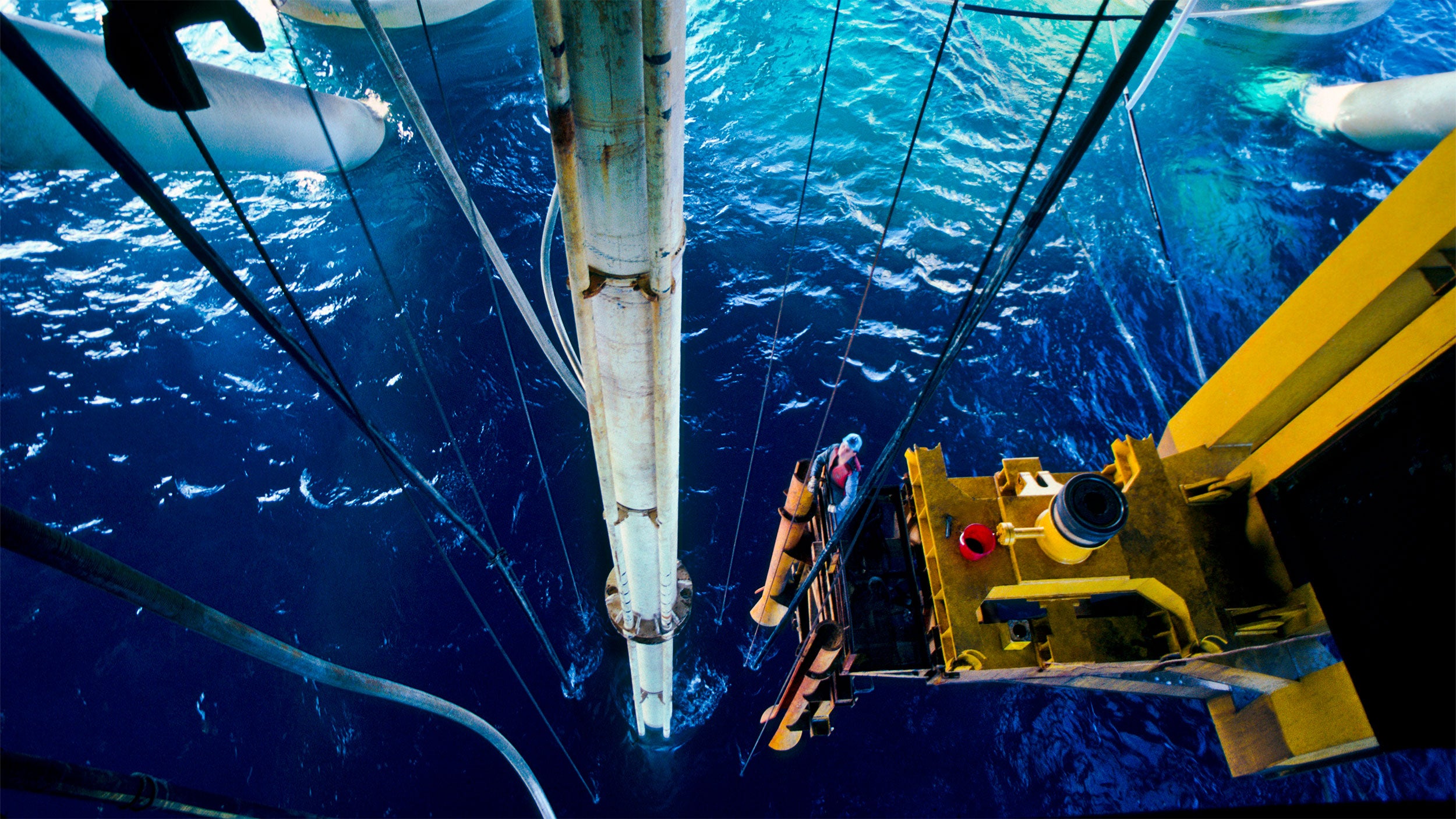

Download PDFDeepwater

Mitigate sustained casing pressure (SCP) in deepwater campaign

Africa

Sustained casing pressure (SCP), or annulus pressure buildup (APB), can challenge well designs. A confined annulus is created when the top of cement (TOC) reaches the previous shoe and the trapped incompressible fluid in the annulus cannot expand with temperature changes. As a result, the annulus pressure increase can lead to internal casing collapse, external casing burst, or packoff failure.

An operator in Africa drilling deepwater wells designed the TOC below previous casings to avoid annulus pressure buildup from the trapped incompressible fluid. This method worked during previous operations because the sand formations were deeper than the previous shoes for the intermediate and production sections. However, in the latest drilling campaign, sand formation was close to the previous casings and new regulations required the operator to cover those sands. This meant the TOC had to reach above the previous casing shoe and inside the casing-to-casing annulus. The operator needed a plan to mitigate the risk.

Halliburton identified an optimized solution to mitigate SCP. The proposed solution involved the placement of a compressible fluid in the casing-to-casing annulus to manage the pressure increase when the well is placed on production. Halliburton cemented the liner with a VersaFlex® expandable liner hanger (ELH), followed by a combined 10 3/4-in. × 9 5/8-in. tieback in the two wells selected for the trial. A foamed spacer was placed in the annulus between the tieback and the previous 13 3/8-in. casing.

The operator simulated the required volume of nitrogen to trap in the annulus. iCem® cementing service was used to calculate the liquid volume of foamed cement necessary to trap the predetermined nitrogen volume in each well. Halliburton proposed a 14.5-lbm/gal Tuned® Spacer E+™ cement spacer base density foamed to 10.8 lbm/gal. Unfoamed 10-lbm/gal Tuned Spacer E+ cement spacer was pumped ahead and behind the foamed spacer to separate it from the 8.7-lbm/gal NAF mud.

lbm/gal. foamed spacer

Sustained casing pressure

Success and planned for use in future campaigns

The operator and Halliburton executed and completed the wells. The foamed spacer was placed in the annulus of the 10 3/4-in. × 9 5/8-in. tieback. The liquid and nitrogen rates were pumped as planned, followed by the activation of the tieback hanger seals. The foamed spacer application helped prevent SCP and costly remediation. The operator plans to use this technique for future campaigns.

Cementing barrier design and tailoring digital twin software that enables real-time job monitoring, evaluation, and instantaneous barrier validation.

Delivers a low-to-moderate load bearing without sacrificing its gas-tight sealing capability or reliability