Search

Search

Search

Search

ChannelFix cement additive is a swelling solution designed to place dependable barriers in unconventional reservoirs

Talk to an expertConstant increases in both the length of well laterals and the speed of drilling continue to create new challenges for operators. Efficiency gains in long laterals are driving increased demand on the resilience of the cement sheath. Stage counts have tripled across North America, while laterals have nearly doubled in length. To meet these challenges, operators need an increase in cement barrier dependability. ChannelFix is the advanced swelling solution designed to place dependable barriers in the expanding unconventional market.

ChannelFix cement additive can provide the reassurance of a barrier for stimulation, even when mud removal is compromised.

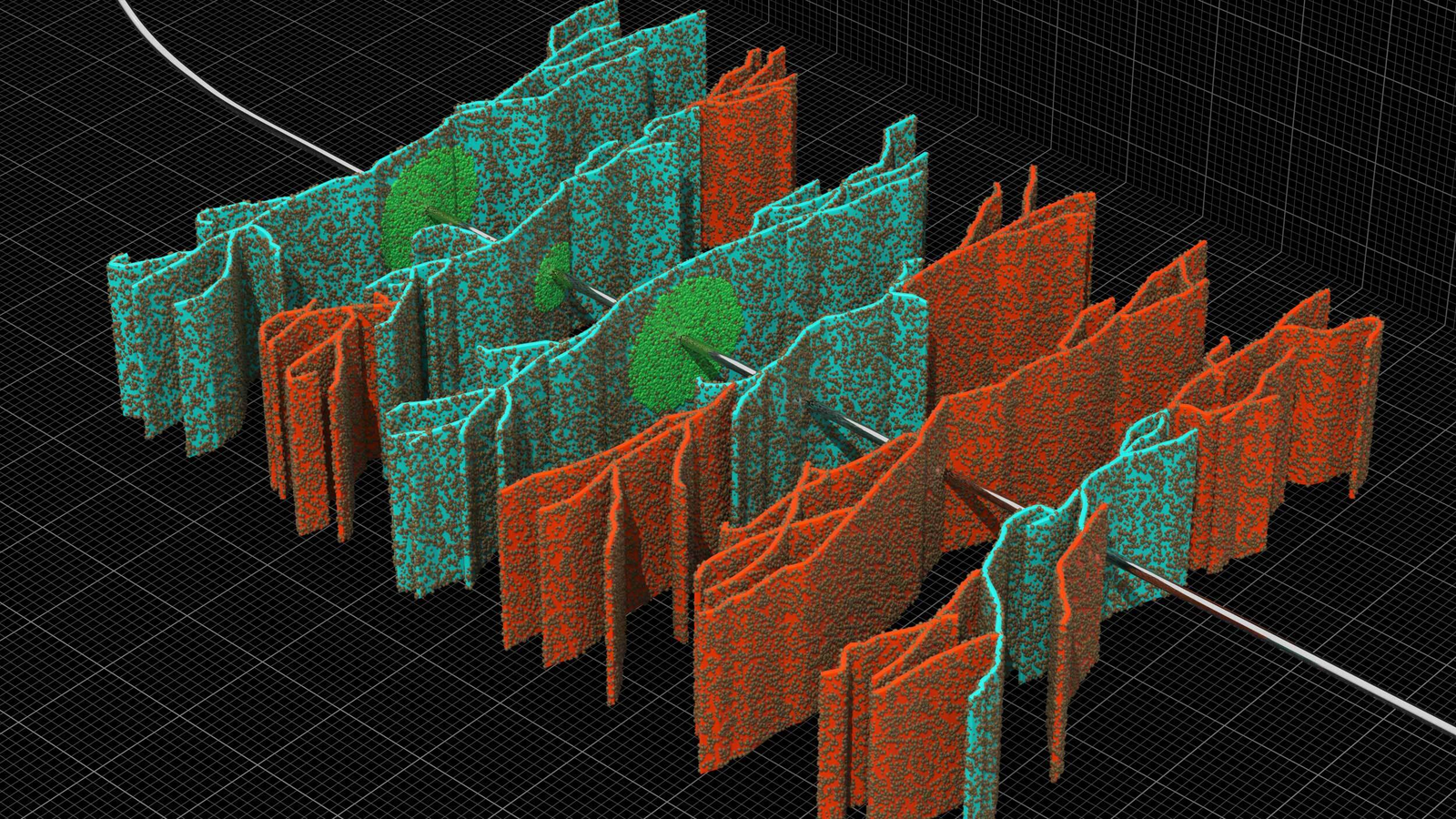

Successful development of an unconventional field requires a constant focus on driving efficiencies and maximizing production per lateral foot. If a reservoir is under-stimulated, economics can be compromised. Under-stimulation can often occur due to immovable mud channels in the annulus that allow the treatment to communicate with previous stages. This challenge is amplified by brittle cement sheaths that are not tailored for intensive stimulation. The result: a poorly producing well with a failed cement barrier.

ChannelFix cement additive provides the reassurance of a barrier for stimulation, even when mud removal is compromised. Through contact with an oil-based mud (OBM) or a synthetic-based mud (SBM), the additive will swell to fill the channel and create a barrier capable of withstanding over 2,500 psi per 10 feet (3 meters) of annular space. With increased elasticity, the barrier is also fit to withstand the many pressure cycles of a typical unconventional completion.

Advantages:

Helps provide increased cement sheath elasticity

Controlled swelling in the presence of hydrocarbons

Compatible with conventional cement slurries

Effective up to 350°F (176°C)

Improved zonal isolation

Higher resistance to cyclic loading