Search

Search

Search

Search

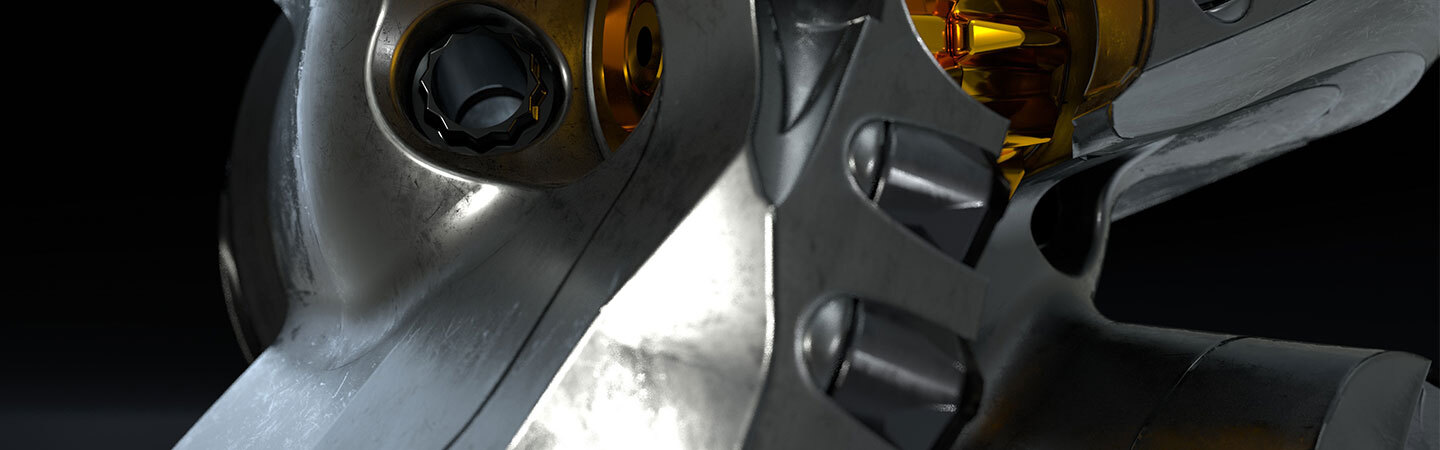

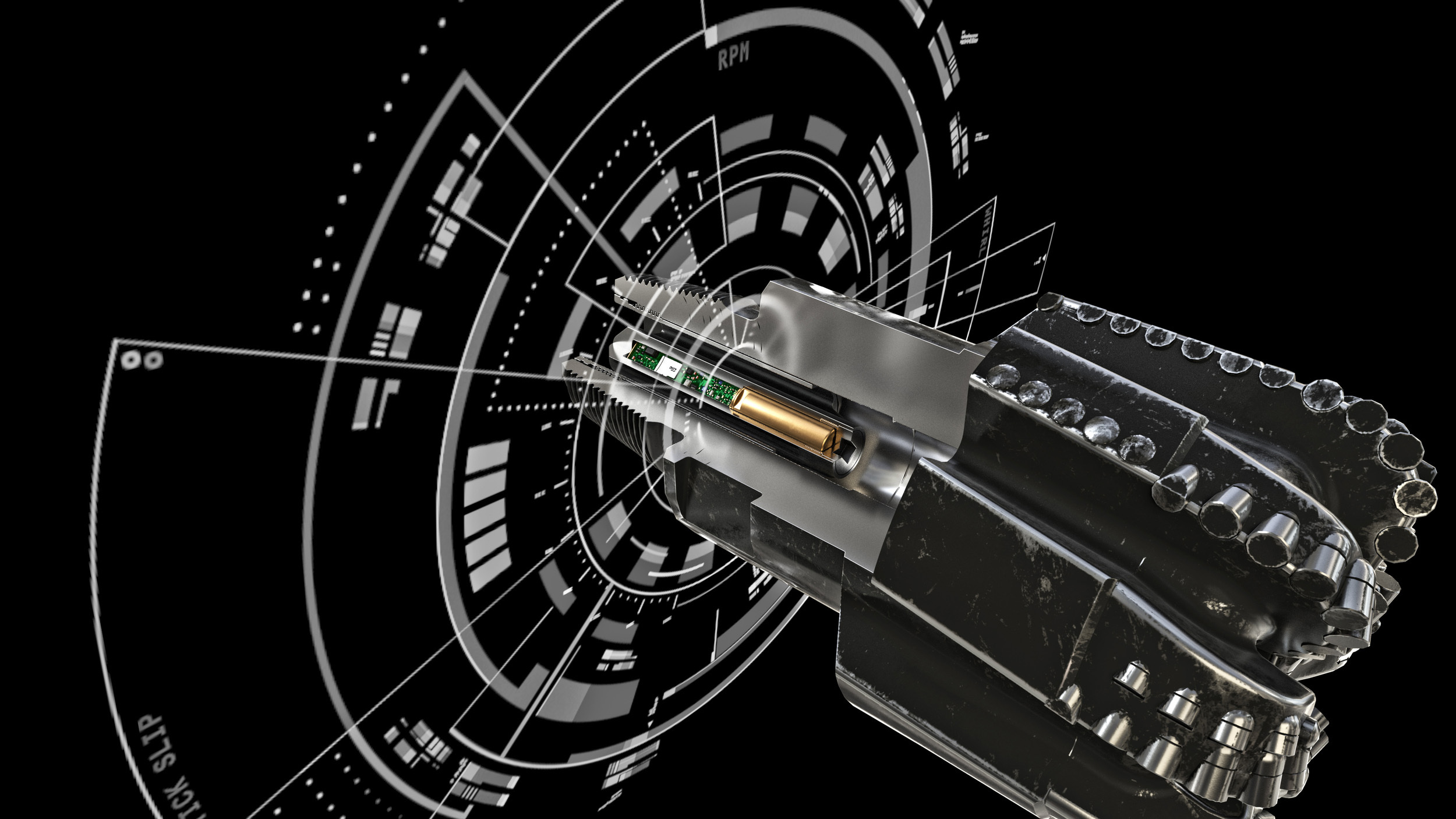

Achieving optimal drilling performance requires efficient conversion of mechanical energy into rock cutting and evacuation. Cerebro® in-bit sensors provide direct, in-bit measurements of vibration and rotational speed. Utilizing the insights provided by Cerebro and the Design at the Customer Interface (DatCISM) process, we collaborate to improve drilling efficiency through bit design, bottom hole assembly, and parameter selection. Improved drilling efficiency will increase rate of penetration and run length, ultimately lowering well construction costs.

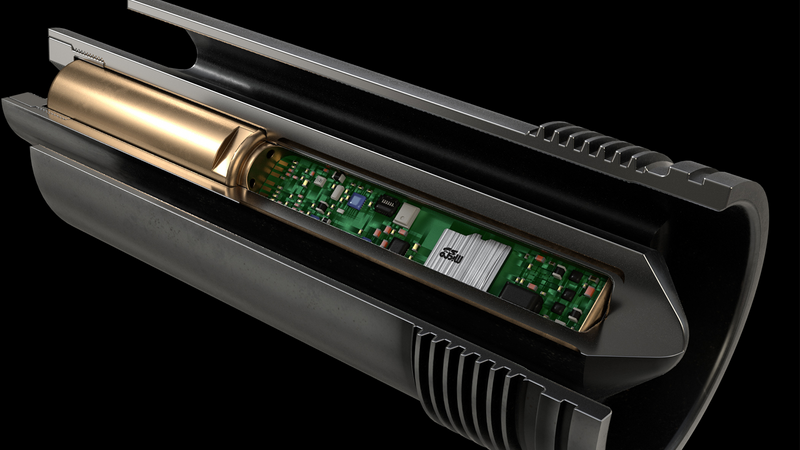

Cerebro further advances our communication with the drill bit by capturing data as close to the cutting structure as possible.

New technology that obtains performance data directly from the drill bit.

1:54

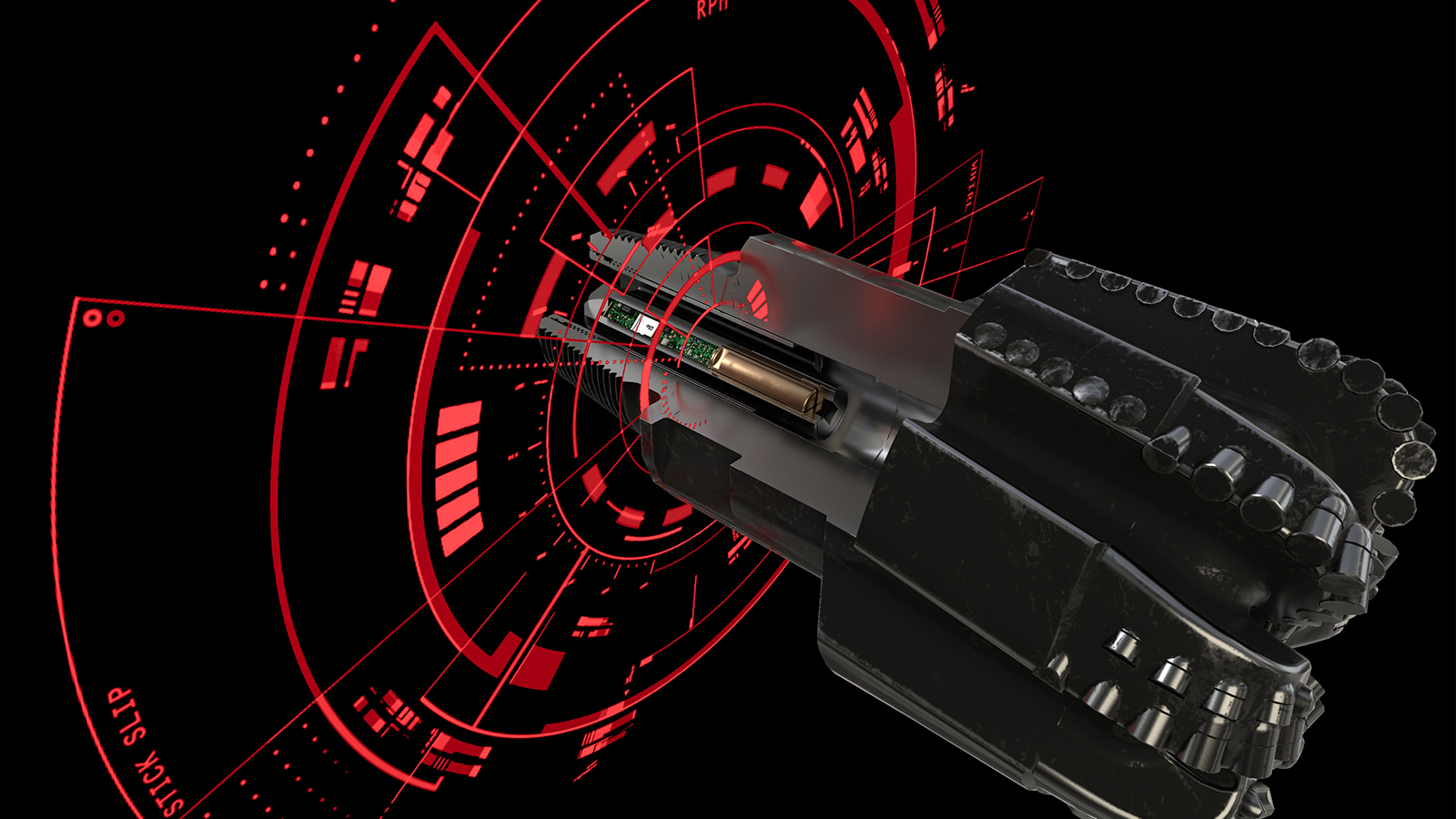

The Cerebro data-capturing system captures the most complete picture of drill bit performance to understand where bit damage occurs and where inefficiencies are located. It measures a variety of data points, including lateral and axial vibration, torsional resonance, whirl, and stick-slip.

From surface to final depth, operators are given the data they need to create a holistic picture of the drilling environment and make effective, data-driven decisions.

Halliburton's Cerebro® in-bit sensor drives Cruzer™ depth-of-cut rolling element and Shyfter™ cutters to deliver outstanding curve performance in North Dakota.

Cerebro® electronic data capture at the drill bit mitigates stick-slip, while improving ROP and drill bit conditions, allowing drill to kick-off point in 1 run.