Search

Search

Search

Search

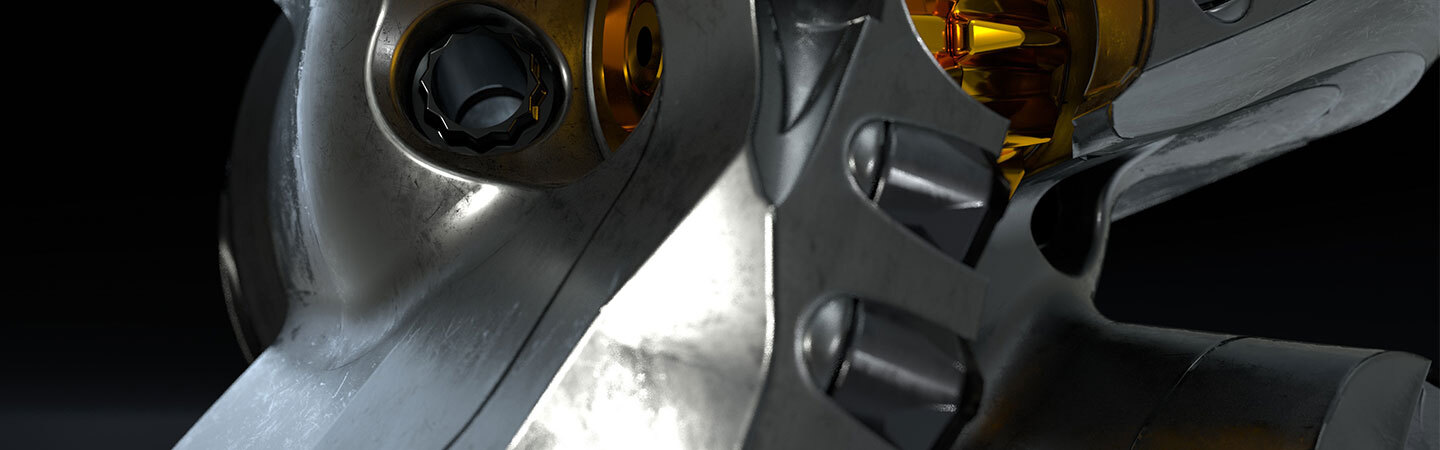

The Cruzer depth-of-cut rolling element is an enhancement feature available on Halliburton’s fixed cutter drill bits. Designed to improve overall drilling economics by reducing torque and increasing ROP, its benefits include durability, steerability, and consistency of results. The Cruzer rolling element is particularly effective in applications requiring more stabilized control of the directional drilling process. The depth-of-cut rolling element incorporates the latest engineering advancements.

Case Study / Williston Basin

Cruzer™ rolling element technology helps reduce average on-bottom time to drill the curve by 43 percent.

Read case studyThe Cruzer depth-of-cut rolling element is designed to improve overall drilling economics by reducing torque and increasing ROP. The rolling element is particularly effective in applications requiring more stabilized control of the directional drilling process.

The Cruzer element is an innovative drill bit technology designed to increase tool face control and maximize drilling efficiency.

02:40

The GeoTech® GTD55DCU drill bit helped us reduce our drilling time and achieve a record curve run in North Dakota by improving tool face control with the Cruzer element.