Search

Search

Search

Search

First GeoTap® IDS Fluid Sampling-While-Drilling Service in a Potentially Corrosive Environment

Download PDFDeep Water

Collect fluid samples while drilling in deep water environment

Offshore, West Africa

Working from a semi-submersible rig offshore, an operator was focused on a horizontal deep water well. The operator needed to understand the fluid properties of the reservoir while reducing well time and costs.

The operator needed to collect fluid samples while drilling in a potentially corrosive environment. The contamination from drilling fluids needed to be minimized to ensure quality samples were retrieved for reservoir characterization. Normally, fluid sampling would be accomplished using a vertical or low-angle directional pilot well to run gravity-conveyed wireline logging tools; however, to reduce well time, worked with the operator to determine a viable solution.

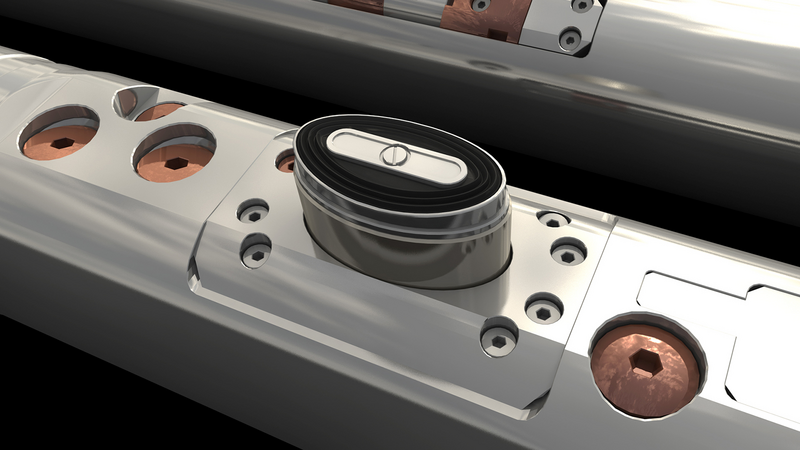

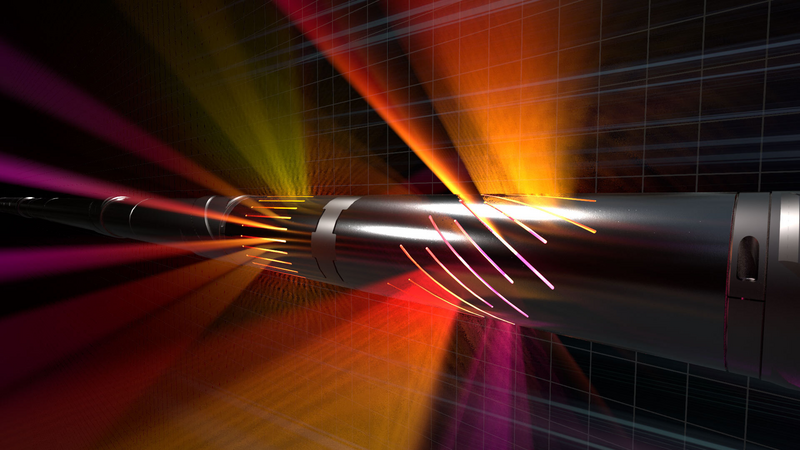

The Drilling Engineering Solutions team recommended including the GeoTap® IDS fluid identification and sampling service in the bottom hole assembly (BHA) to acquire fluid samples while drilling. The GeoTap IDS service delivers real-time reservoir characterization through logging-while-drilling. Due to the potentially harsh environment, specific technical upgrades to key components and sensors were required to facilitate a safe and successful operation. The component and sensor upgrades were implemented to meet the required specifications to safely operate reservoir and gather data to facilitate drilling, completion, and production decisions. Close collaboration between the customer and the Halliburton Technology Center in Houston enabled the configuration upgrade of the standard GeoTap IDS service and remain on schedule. In addition to the upgraded GeoTap IDS service, the BHA included the iCruise® RSS, EarthStar® ultra-deep resistivity service, and ADR™ azimuthal deep resistivity service. These additional services allowed pro-active steering decicions to reach the drilling targets.

Fluid identification and sampling solution.

Ultra-deep resistivity service mapping reservoir and fluid boundaries up to 225 feet from the wellbore.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs