Search

Search

Search

Search

Formation testing and sampling while drilling solution

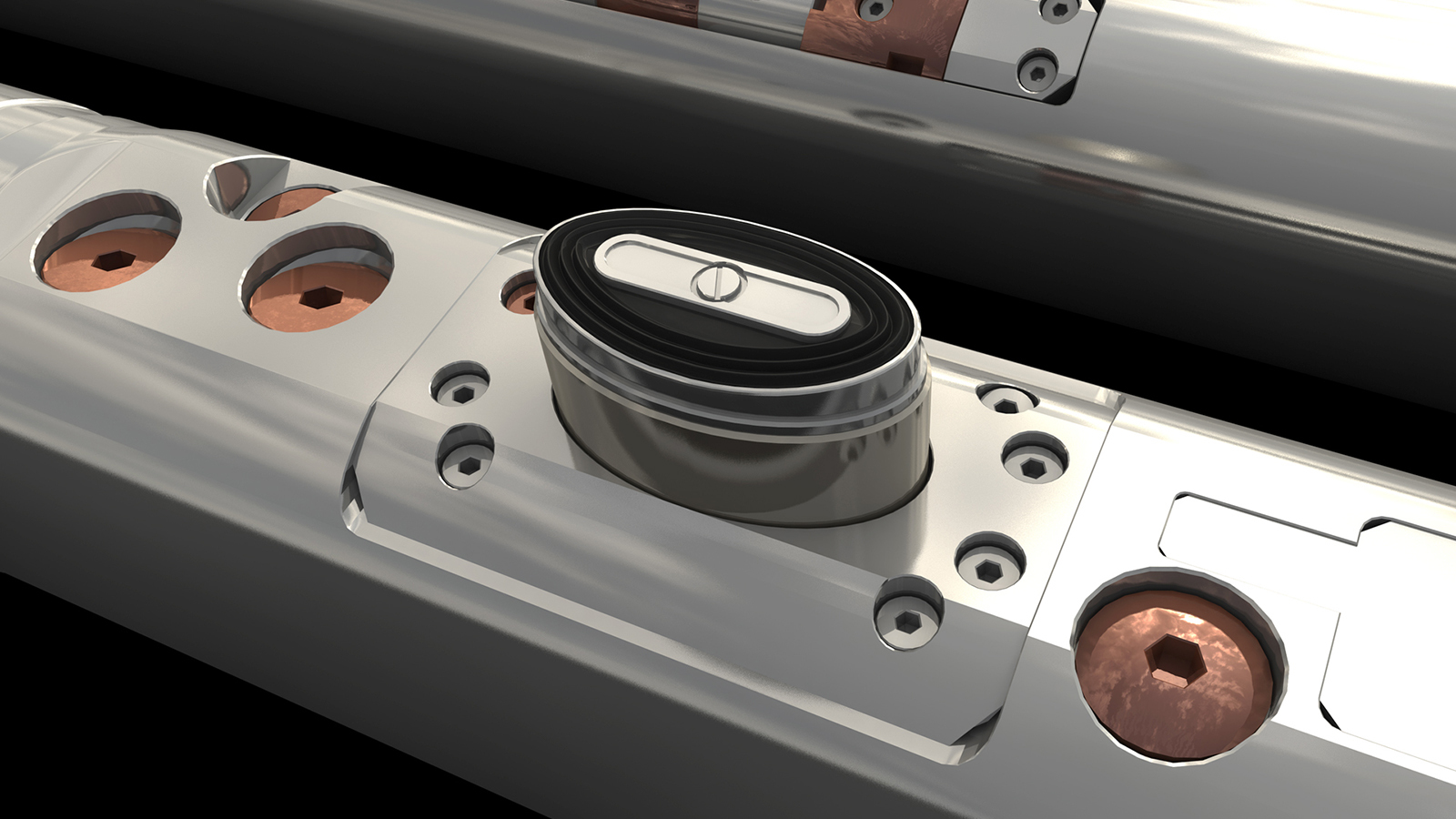

Talk to an expertThe GeoTap IDS fluid identification and sampling service enables the recovery of reservoir fluid samples while drilling. Operators are able to acquire, recover, and identify multiple samples of uncontaminated formation fluids within hours, rather than days, thus reducing well time and maximizing asset value.

The GeoTap IDS service provides true formation testing while drilling, minimizing the contamination from drilling fluids and reducing pump-out times for clean samples. The data is recovered rapidly leading to faster and more accurate decision making such as optimizing wellbore placement to achieve maximum production over the lifetime of the reservoir.

The new GeoTap IDS sensor from Sperry Drilling services enables reservoir fluid samples to be recovered with LWD technology for the first time

05:35

The GeoTap IDS service, combined with additional logging-while-drilling solutions, eliminates the time and cost associated with drilling low-angle pilot wells. Operators can now reduce their risks and uncertainties by running GeoTap IDS service in all the sections of the well and get real-time pressure testing while drilling and rapid fluid identification and sampling.

An industry first, the GeoTap® IDS fluid identification and sampling service eliminates the need for pilot wells and dedicated wireline trips to obtain multiple fluid samples, completing a full package of formation testing while drilling capabilities.