Search

Search

Search

Search

iCruise® intelligent rotary steerable system places well accurately in zone

Download PDFUnconventionals

Maximize reservoir contact in a long lateral section

Springer Shale Formation, Oklahoma

Collaborated with the operator to engineer a drilling solution:

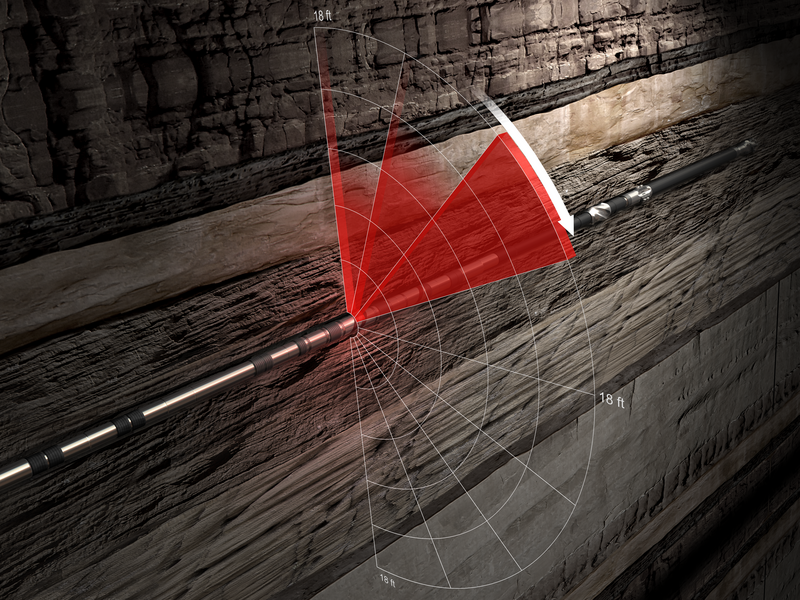

An operator drilling in the Springer shale formation — located in the South Central Oklahoma Oil Province (SCOOP) play — needed to maximize reservoir contact in a long lateral section, traversing a formation where dip angles varied from 89° to 93° over a very short interval. Halliburton Sperry Drilling recommended deploying the new iCruise intelligent rotary steerable system (RSS), which is designed to reduce well time and place wells accurately. The system was able to reduce dogleg severity, while also precisely steering the well in the zone for the entire 5,226-foot (1,593-meter) lateral, thus helping the operator maximize asset value. This precise control was maintained by highly accurate directional data processed at the rate of 1,000 measurements a minute.

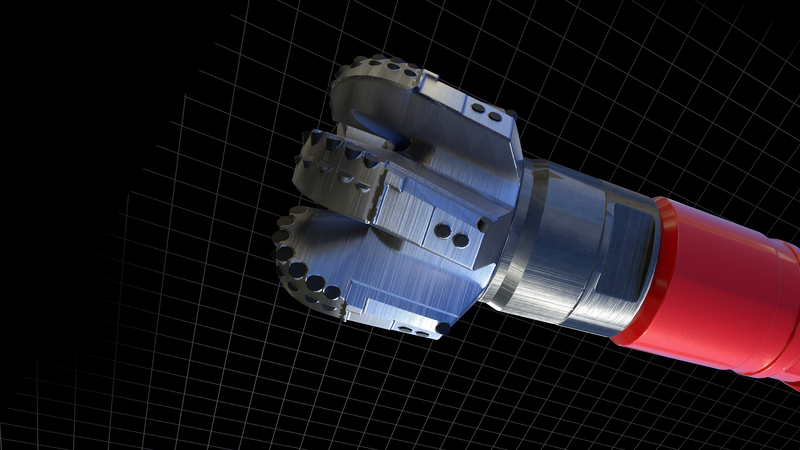

Halliburton collaborated with the operator so that the iCruise bottomhole assembly (BHA) was properly configured to achieve the directional drilling objectives. The BHA included the ADR™ azimuthal deep resistivity service for interpreting formation dips, along with the iCruise intelligent RSS matched with a GeoTech® (GTi) drill bit designed via the Design at the Customer Interface (DatCISM) process. Direction by Design® (DxD) software was used to add enhanced capabilities that gave the RSS an increased rate of penetration (ROP), along with more accurate steerability and better control.

This engineered drilling solution enabled the operator to drill 5,226 feet (1,593 meters) in 105.5 IADC hours, with an average rate of penetration (ROP) of 49.5 feet (15 meters) per hour — all while traversing the steep inclines encountered in this geological environment. The rugged design of the iCruise RSS allowed the section to be drilled in a one-bit run.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs

ADR's deep-reading geosteering and resistivity sensors deliver over 2,000 unique measurements for accurate petrophysical analysis and wellbore placement.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.

DatCI is a powerful service platform used to optimize bit and drilling performance through in-depth planning, bit design, and post-well evaluation.