Search

Search

Search

Search

iCruise® intelligent rotary steerable system drills Spraberry Group faster than competition offsets

Download PDFUnconventionals

Create a drilling solution to complete a horizontal production section

Midland, Texas

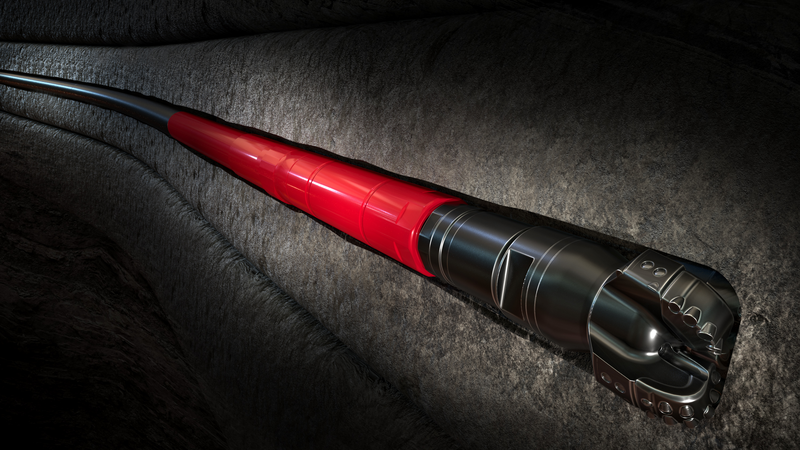

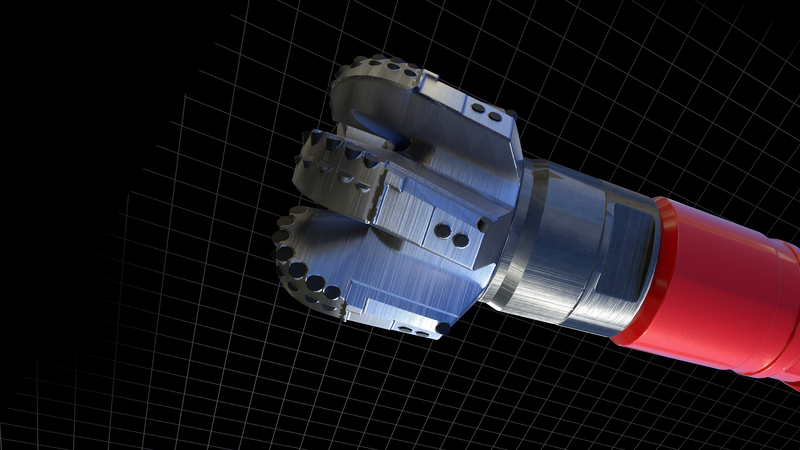

A major operator in the Midland basin collaborated with Halliburton to drill a 8.5" horizontal production section improving drilling performance compared to competitor's offset runs in the same field, reducing lateral drilling time by ~20%. Halliburton Sperry Drilling delivered an engineered drilling solution, including the iCruise® intelligent rotary steerable system (RSS), 7" StrataForce™ high-performance motor, and 8.5” Geotech® GTi65DHEO drill bit. The 6.75” iCruise RSS drilled the 2.5-mile lateral in one run. CruiseControl™ technology was utilized to hold inclination and azimuth delivering a high quality wellbore, helping the operator maximize asset value.

Feet Drilled

average rate of penetration (ROP) per hour in feet

Drilling-Time Reduction

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

The Halliburton StrataForce™ motor delivers increased power and torque for optimal drilling.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.